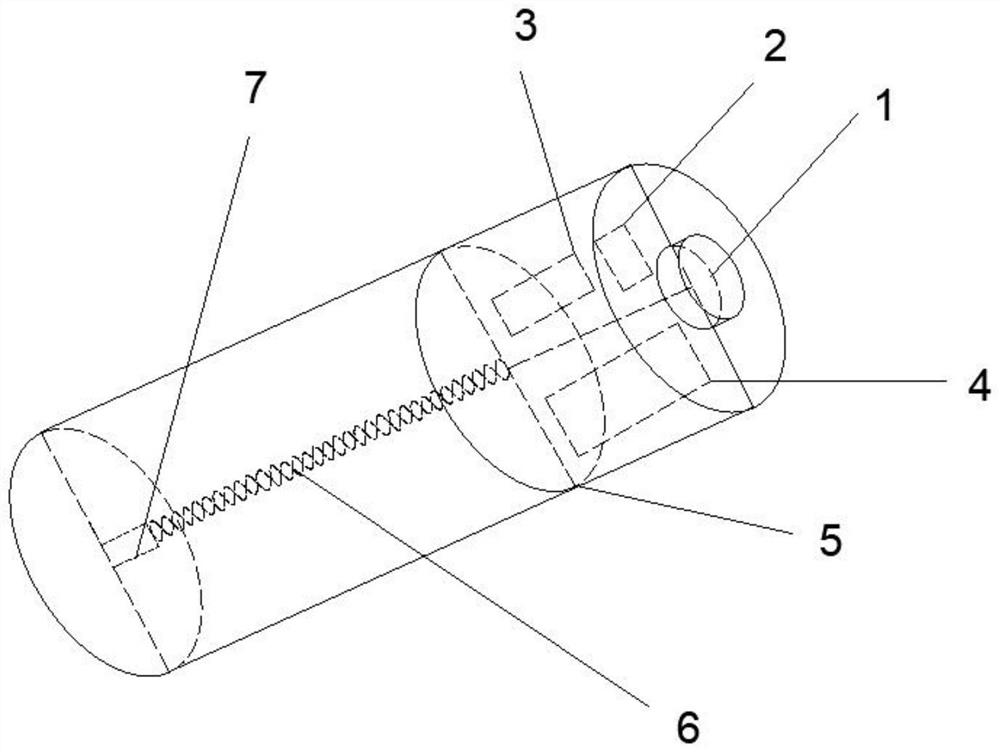

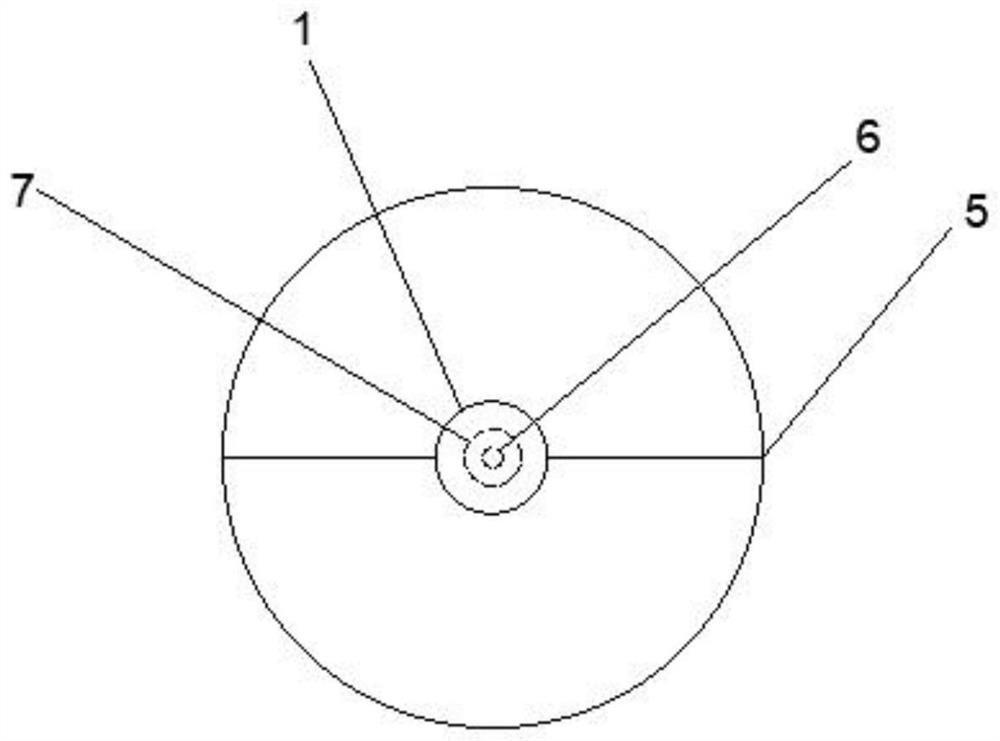

Device for monitoring whether charge in blast hole is completely detonated or not

A blasthole and built-in technology, applied in blasting and other directions, can solve the problems of coil interval, explosive stagnation, detonation interruption, etc., and achieve the effect of accurate monitoring effect, low learning cost, and convenient completion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0016] In the open-air deep hole blasting and building demolition blasting project, in the blast hole charging stage, if the top of the blast hole is used to detonate, the power switch of the present invention is turned on, and the present invention is inserted horizontally into the bottom of the charge roll at the bottom of the blast hole; The bottom of the hole is detonated, the power switch of the present invention is turned on, and the present invention is inserted horizontally into the top of the charge roll at the top of the blast hole. After the detonation, the enameled wire melts and connects under the action of the detonation wave, and the radio frequency signal generating module instantly transmits a signal to the computer, which proves that the explosive is completely detonated and no residual explosive remains; Response, remaining drug residue, find out the location of residual drug through the positioning module, and process it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com