Detection method and detection system of electronic compass

An electronic compass and detection system technology, applied in the field of detection, can solve the problems of magnetization damage of components, waste of manpower and time, etc., and achieve the effect of simple assembly, quick use and short detection time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

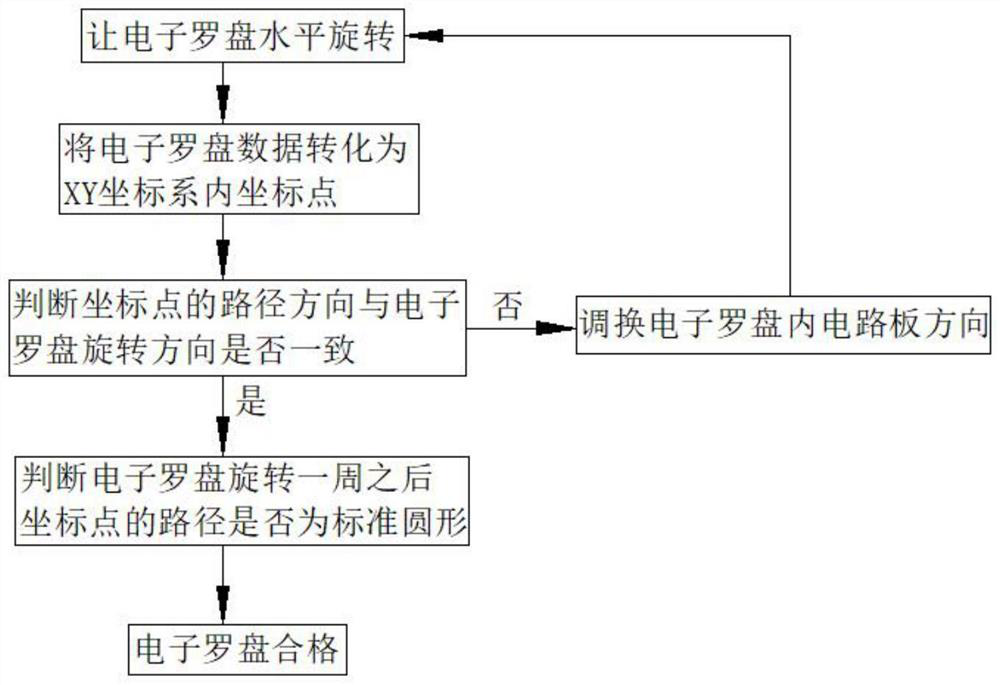

[0063] Such as figure 1 Shown, a kind of detection method of electronic compass comprises:

[0064] (1) Let the electronic compass rotate horizontally,

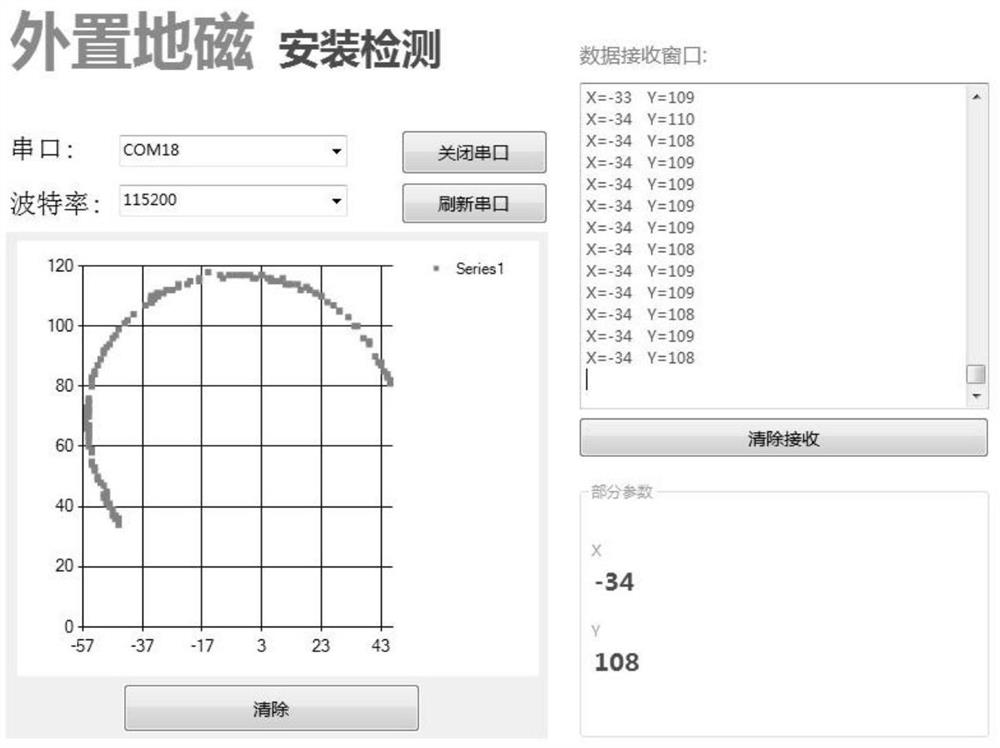

[0065] (2) Convert the electromagnetic field modulus generated by the electronic compass into coordinate points in the XY plane;

[0066] (3) Whether the path direction of the coordinate point is consistent with the horizontal rotation of the electronic compass to judge whether the circuit board installation of the electronic compass is correct;

[0067] (4) Let the electronic compass rotate one circle horizontally, and judge whether the electronic compass is damaged by magnetization according to the proximity of the coordinate point path to the standard circle;

[0068] (5) The electronic compass that satisfies the detection of steps (3) and (4) at the same time is a qualified product.

[0069] Wherein, the detection of the step (3) is performed with priority relative to the detection of the step (4).

[0070] In this em...

Embodiment 2

[0072] Such as figure 1 As shown, different from the above embodiments, in this embodiment, the detection of the step (3) is performed simultaneously with the detection of the step (4).

[0073] At the same time, regardless of whether there is a problem with the circuit board, it can quickly detect whether the electronic compass is damaged by magnetization and whether the magnetic field value is normal; when it is confirmed that the electronic compass is normal, the test can be passed on the spot. Repair speed.

Embodiment 3

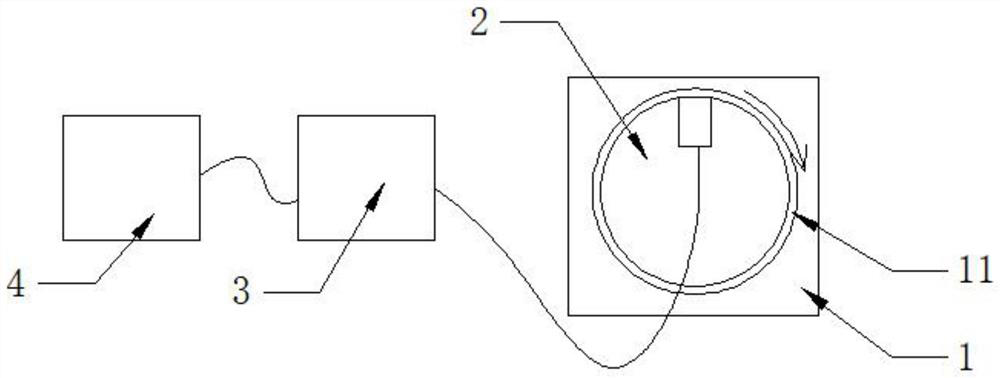

[0075] Such as figure 1 , figure 2 As shown, in this embodiment, a detection system of an electronic compass is provided, including:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com