Visual oil film measuring device suitable for high-low pair oil-gas two-phase mixed lubrication

A measuring device and mixed lubrication technology, applied in measuring devices, instruments, etc., can solve the problems of low accuracy, narrow application range, personnel error, etc., and achieve the effect of good measurement effect, high measurement accuracy and wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] In order to clearly illustrate the technical characteristics of this patent, the following describes this patent in detail through specific implementation methods and in conjunction with the accompanying drawings.

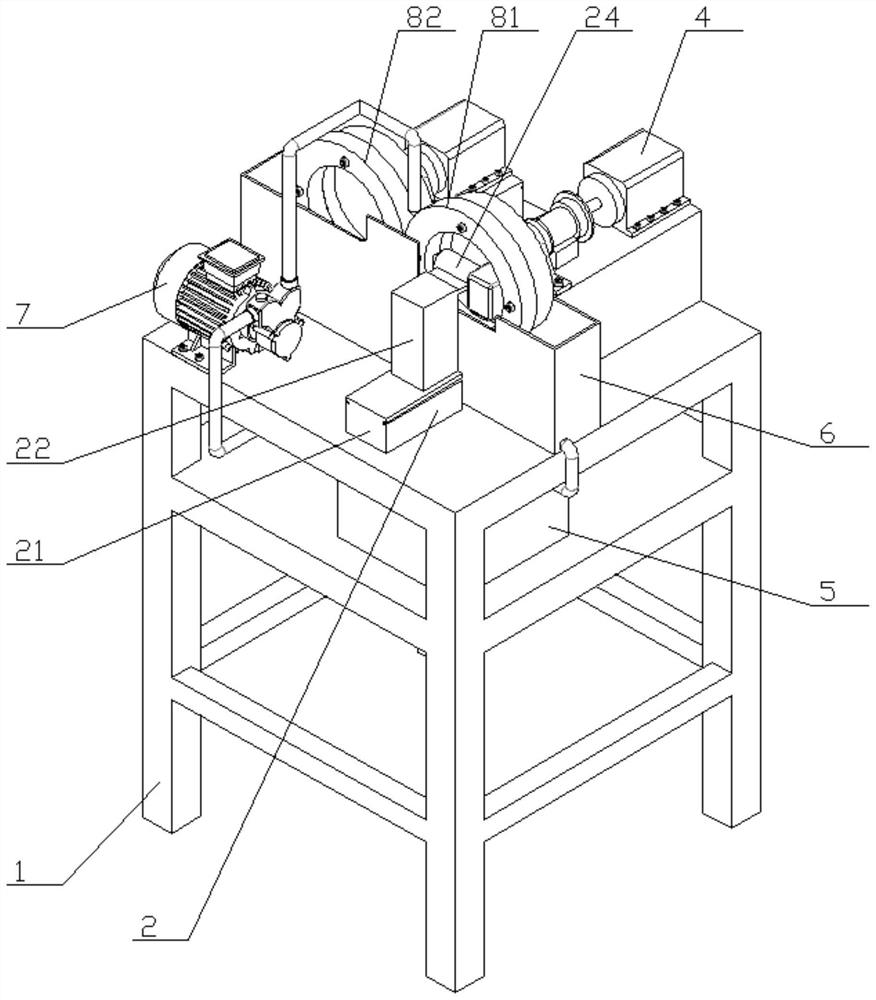

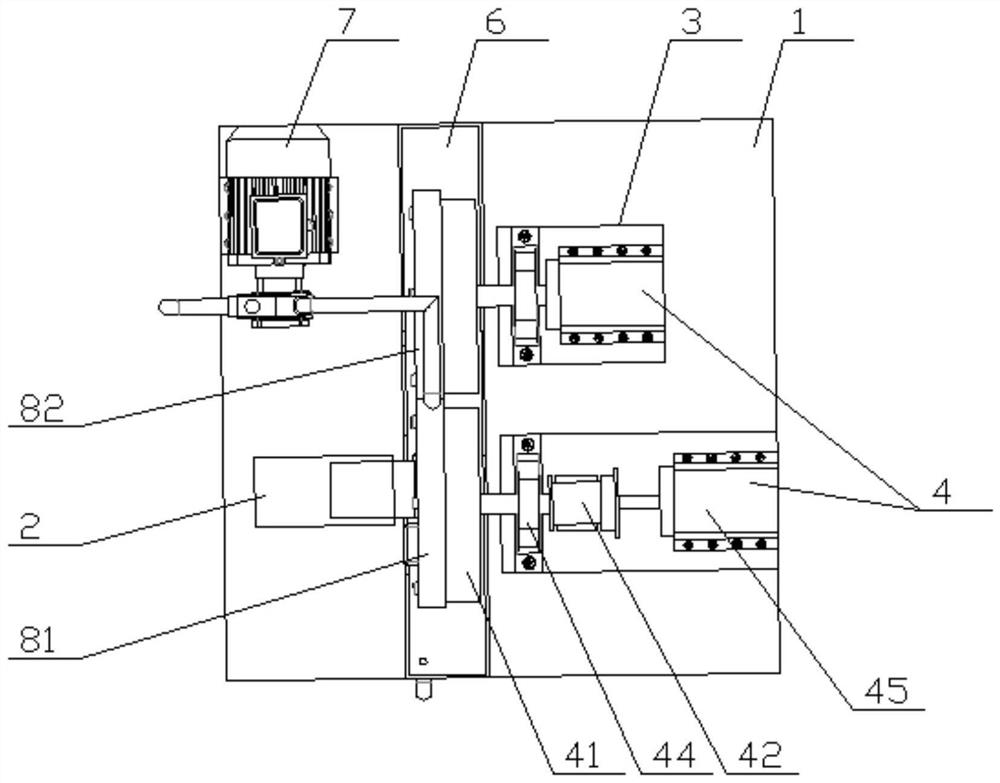

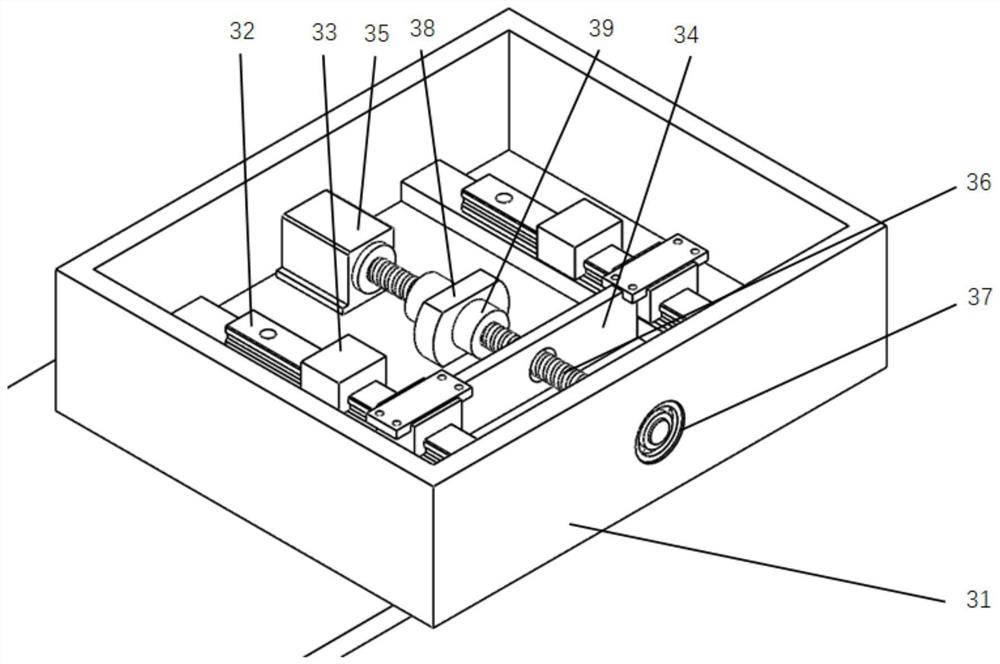

[0053] The main structure of the visual oil film measurement device applicable to high and low auxiliary oil-gas two-phase mixed lubrication of the present invention includes a support platform 1, a measurement device 2, a horizontal displacement device 3, a rotary drive device 4, an oil storage tank 5, a recovery oil tank 6 and a gas liquid mixing pump7. The support platform 1 is a four-leg support structure at the bottom, and the bottoms of the four feet are fixed by straight rods between each other, a flat plate is arranged in the middle of the four feet, and the top of the four feet is a working platform. Look at the layout on the work platform from a bird's-eye view, such as figure 2 As shown, the upper left corner is the gas-liquid mixing pump 7, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com