A kind of enhanced reverse osmosis off-line cleaning test method

A test method and technology of reverse osmosis, which is applied in the field of water treatment, can solve the problems of lack of function, large difference in water quality of reverse osmosis system, high equipment requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

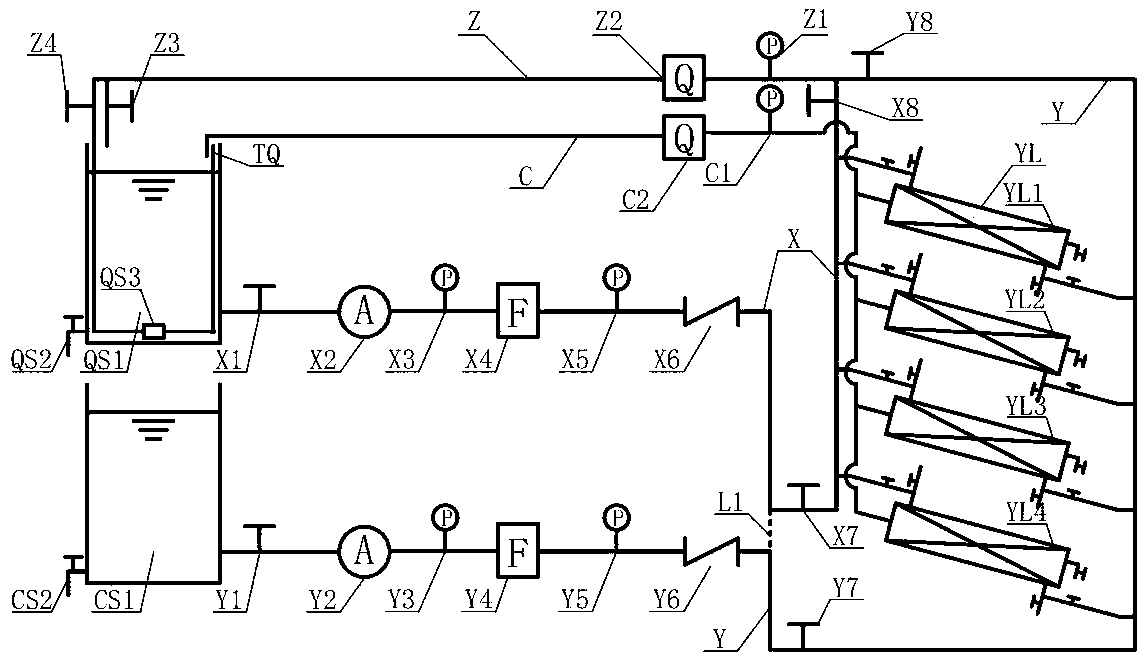

[0068] A kind of enhanced reverse osmosis off-line cleaning test method of the present invention is described in detail. This method relies on the above-mentioned equipment to clean the reverse osmosis membrane. The standardized membrane flux of a new membrane of this type of membrane is 1.79m at 25°C under a pressure of 15.5bar. 3 / h, single membrane 37m 2 , including the following steps:

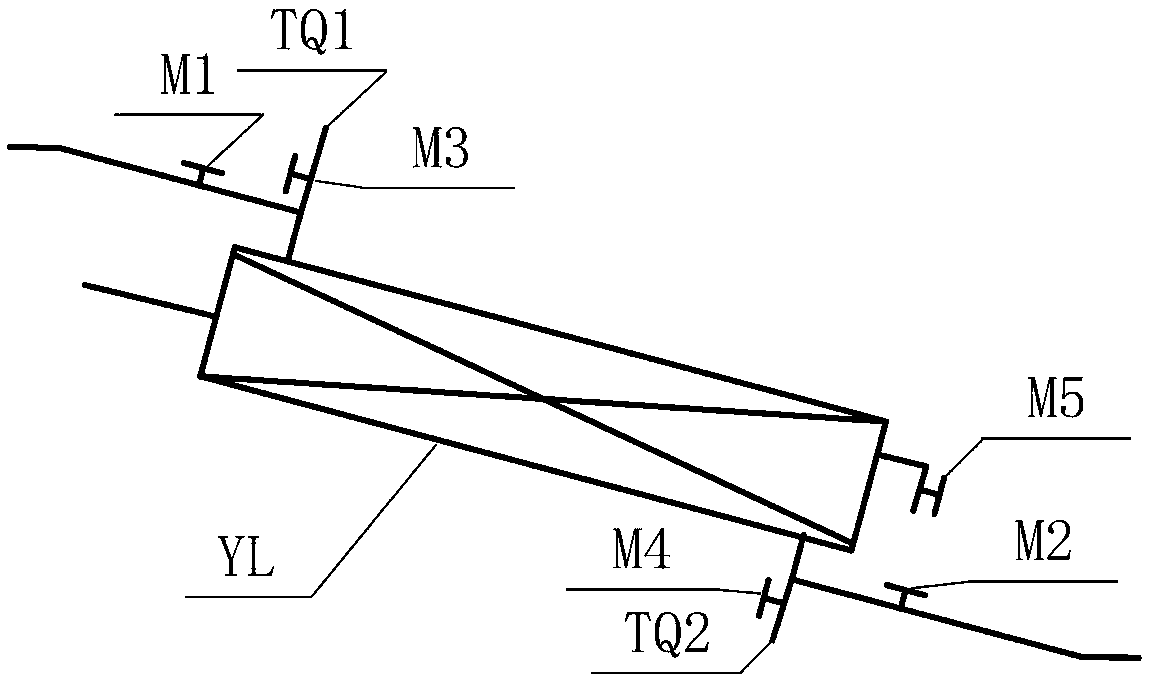

[0069] 1) Pre-washing test: Before the pre-washing test, all the valves of the system are closed, the test water tank (CS1) is filled with test water to the highest water level, and the outlet valve of the test water tank (Y1), the front valve of the water inlet pipe (X7), and the pressure vessel inlet are opened in sequence. Water pipe valve (M1), pressure vessel concentrated water pipe valve (M2), concentrated water pipe rear valve (Y8), return branch pipe valve (Z3), turn on the test pump (Y2), reach the membrane inlet pressure, open the sampling pipe on the sampling pipe Pipe valve (M...

Embodiment 2

[0083] Except step 6) to step 8), all the other are the same as embodiment 1, that is, the present embodiment does not carry out air-drying and foam alkali washing process, and the normalized recovery rate after cleaning is only 76.4%, which is significantly lower than that of embodiment 1, which is 94.4%. , it can be seen that the process of air drying and foam alkaline washing has an important impact on the cleaning recovery effect.

Embodiment 3

[0085] Except step 7) to step 8), all the other are the same as embodiment 1, that is, the present embodiment does not carry out the foam alkali cleaning process, and the standardized recovery rate after cleaning is only 85.3%, which is significantly lower than the 94.4% of embodiment 1. The 76.4% of 2 is slightly increased. It can be seen that the foam alkaline washing process has an important impact on the cleaning recovery effect.

[0086] category Condition Pf △P Cf Y T Cp Q Pp R Inlet pressure pressure drop Influent TDS Recovery rate temperature Permeate TDS actual traffic Permeate pressure Normalized Flow Recovery Rate bar bar mg / L ℃ mg / L m3 / h bar Standardized conditions initial 15.5 0.2 2000 0.15 25.0 37.2 1.79 0.2 100% Example 1 before cleaning 11.0 0.8 2100 0.25 29.8 39.5 0.52 0.0 38.9% Example 1 after cleaning 11.0 0.3 2100 0.26 29.9 32.0 1.30 0.0 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com