Large generator stator transposition bar strand short circuit fault positioning method

A technology of generator stator and transposition bar, which is applied in the direction of fault location, short-circuit test, and electrical measurement. It can solve the problem that the short-circuit fault of strands cannot be effectively located, and achieve reliable and easy-to-implement results in maintenance and testing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

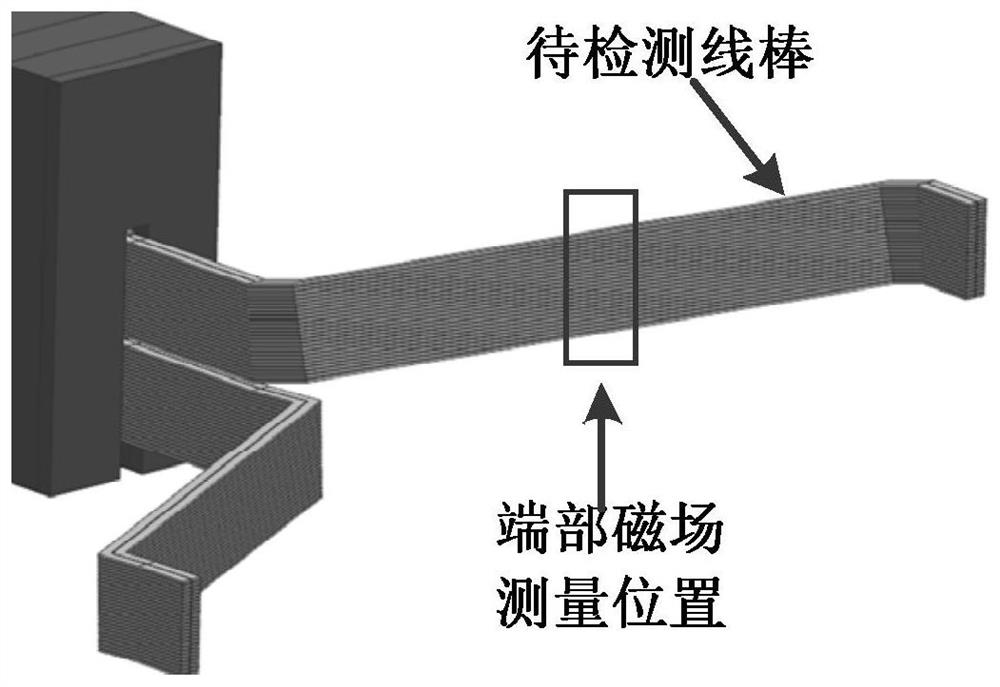

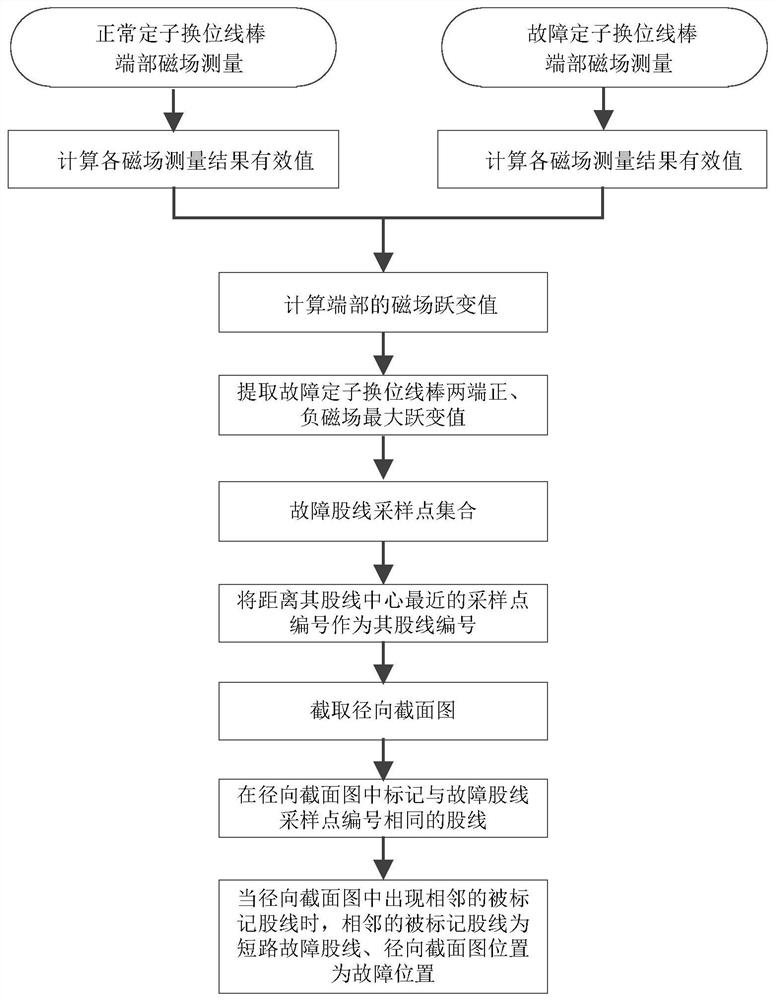

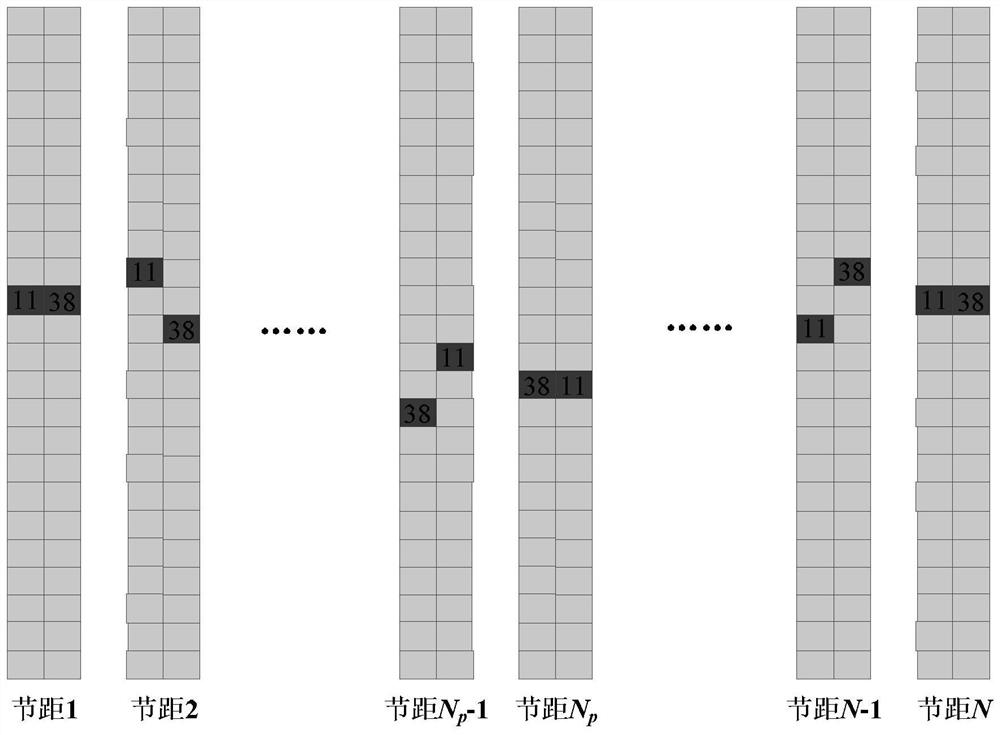

[0038] Specific implementation mode one: refer to Figures 1 to 3 This embodiment will be described in detail. In the method for locating the short-circuit fault of the large-scale generator stator transposition bar strands described in this embodiment, firstly, sampling points are respectively set on the normal and faulty stator transposition bars. Specifically, the end of the stator transposition bar is the part located outside the stator core slot, such as figure 1 As shown, this part has two inflection points, and the straight line between the two inflection points is the middle section at the end of the transposition bar. A line is drawn on the outer surface of the middle section along the midline of the middle section, and the line forms a closed coil. Evenly set multiple sampling points with different numbers on the closed coil, and ensure that there is at least one sampling point on the surface of each strand. The positions of the sampling points on the normal and faul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com