Polyvinyl chloride polymerization production process real-time measurement control system

A production process and real-time measurement technology, applied in the direction of biological neural network model, neural architecture, neural learning method, etc., can solve the problems of tediousness, low precision, lag, etc., and achieve the goal of improving prediction accuracy, strong practicability, and simplified composition Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the embodiments shown in the accompanying drawings.

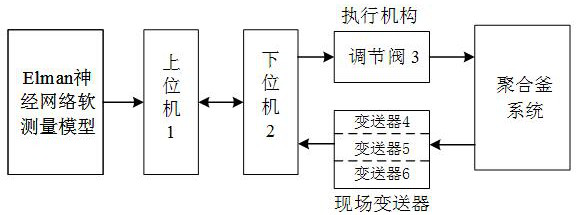

[0025] The system of the present invention collects various data of the polymerization kettle through sensors such as pressure, temperature and flow installed on the polymerization kettle, and field transmitters, and transmits them to the lower computer. The lower computer is connected with the actuator and the upper computer to convert the model signal. The digital signal is transmitted to the host computer. The host computer transmits the signal with the soft sensor model, data processing and analysis, and transmits the analysis result to the soft sensor model (known technology); the result of the soft sensor model predicting the conversion rate of VCM satisfies the requirement Real-time control requirements of the production process.

[0026] As shown in the figure, the system of the present invention includes a field transmitter installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com