Semiconductor device and preparation method thereof

A semiconductor and device technology, applied in the field of semiconductor devices and their preparation, can solve problems such as time-consuming, photoresist stripping, and cost increase, and achieve the effects of improving product performance, low cost, and ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

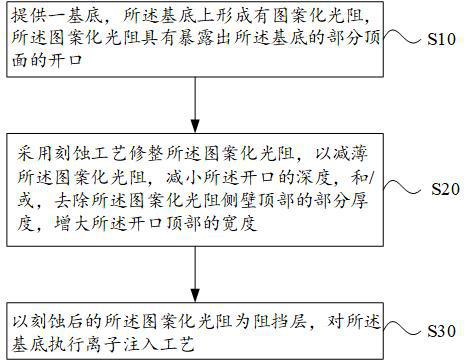

[0039] In order to solve the above technical problems, this embodiment provides a method for manufacturing a semiconductor device, please refer to image 3 ,include:

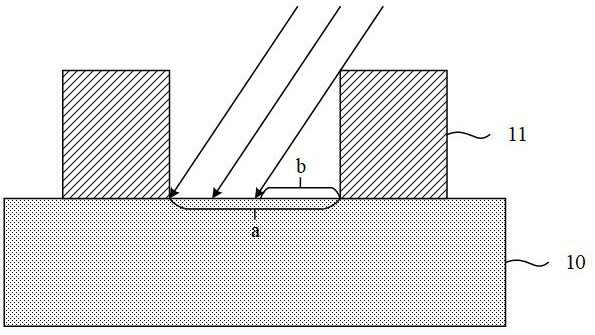

[0040] Step 1 S10: providing a substrate, on which a patterned photoresist is formed, and the patterned photoresist has an opening exposing part of the top surface of the substrate;

[0041] Step 2 S20: trimming the patterned photoresist by using an etching process to thin the patterned photoresist, reduce the depth of the opening, and / or remove the top part of the patterned photoresist sidewall thickness, increasing the width of the top of the opening;

[0042] Step 3 S30: Using the etched patterned photoresist as a barrier layer, perform an ion implantation process on the substrate.

[0043] In this embodiment, the size of the patterned photoresist is adjusted by etching and trimming, so as to at least reduce the thickness of the patterned photoresist, and / or increase the width of the top of the opening, so ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com