Whole-plant chenopodium quinoa willd and corn mixed silage and application thereof

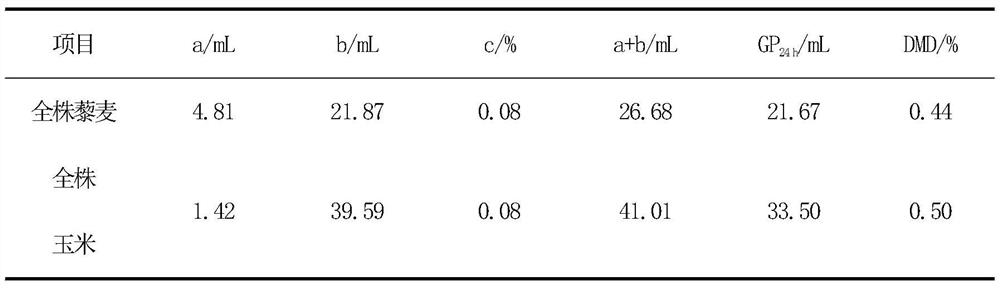

A technology of silage and whole plant corn, which is applied in the field of silage, can solve the problems of less research and reports, and achieve the effects of improving energy conversion capacity, increasing gas production value and dry matter degradation rate, and improving digestion and utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

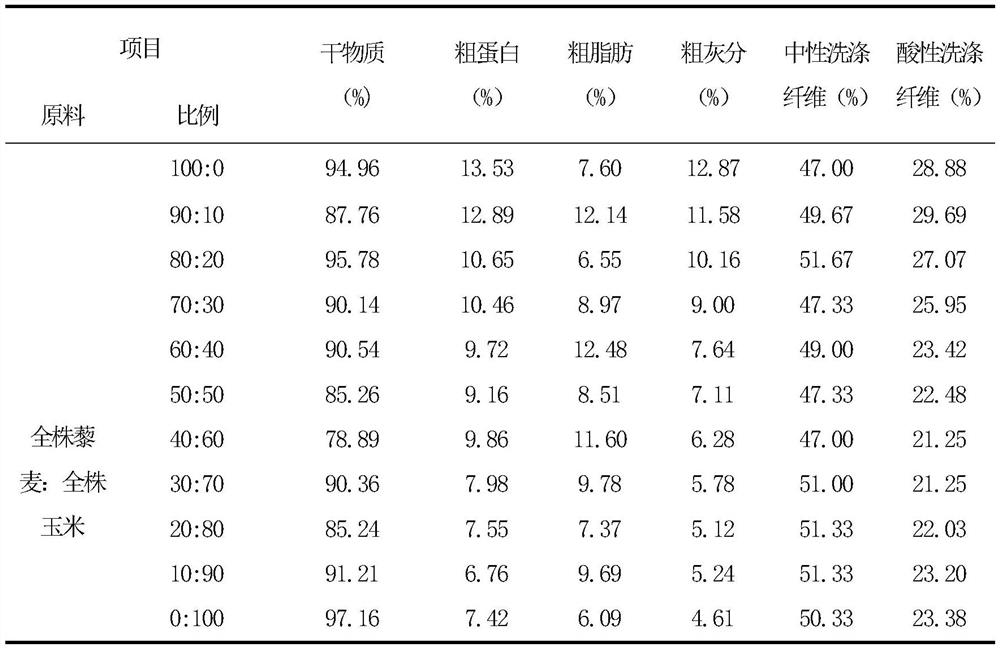

[0017] A kind of silage mixed with whole plant quinoa and corn, comprising whole plant quinoa and whole plant corn at a weight ratio of 90:10, the silage is packed after mixing the whole plant quinoa and whole plant corn in proportion Put it into a 15L barrel and seal the silage for 60 days to get it.

Embodiment 2

[0019] A kind of silage mixed with whole plant quinoa and corn, comprising whole plant quinoa and whole plant corn at a weight ratio of 80:20, the silage is packed after mixing the whole plant quinoa and whole plant corn in proportion Put it into a 15L barrel and seal the silage for 60 days to get it.

Embodiment 3

[0021] A kind of silage mixed with whole-plant quinoa and corn, comprising whole-plant quinoa and whole-plant corn at a weight ratio of 70:30, the silage is packed after mixing the whole-plant quinoa and whole-plant corn Put it into a 15L barrel and seal the silage for 60 days to get it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com