Traditional Chinese medicinal material grinding device for bioengineering

A grinding device and bioengineering technology, applied in grain processing, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of inconvenient cleaning of grinding devices and large powder particles, and achieve easy cleaning, fine powder particles, and convenient use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

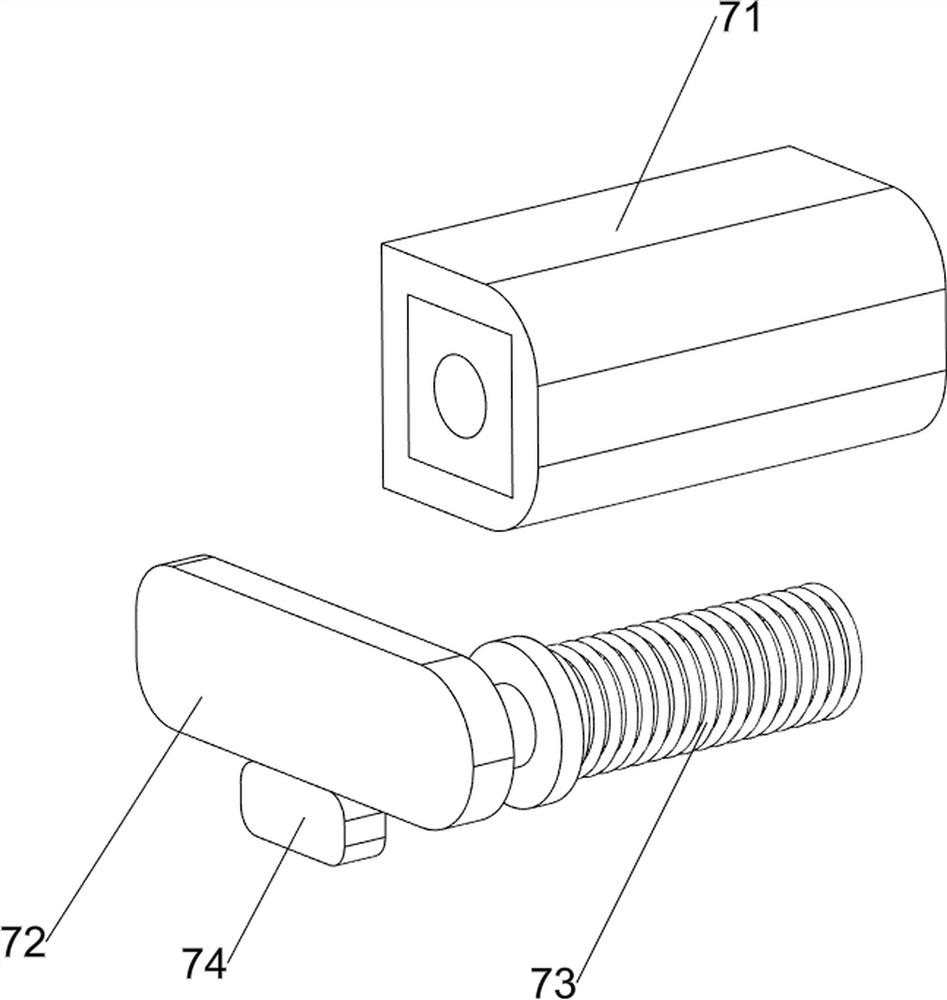

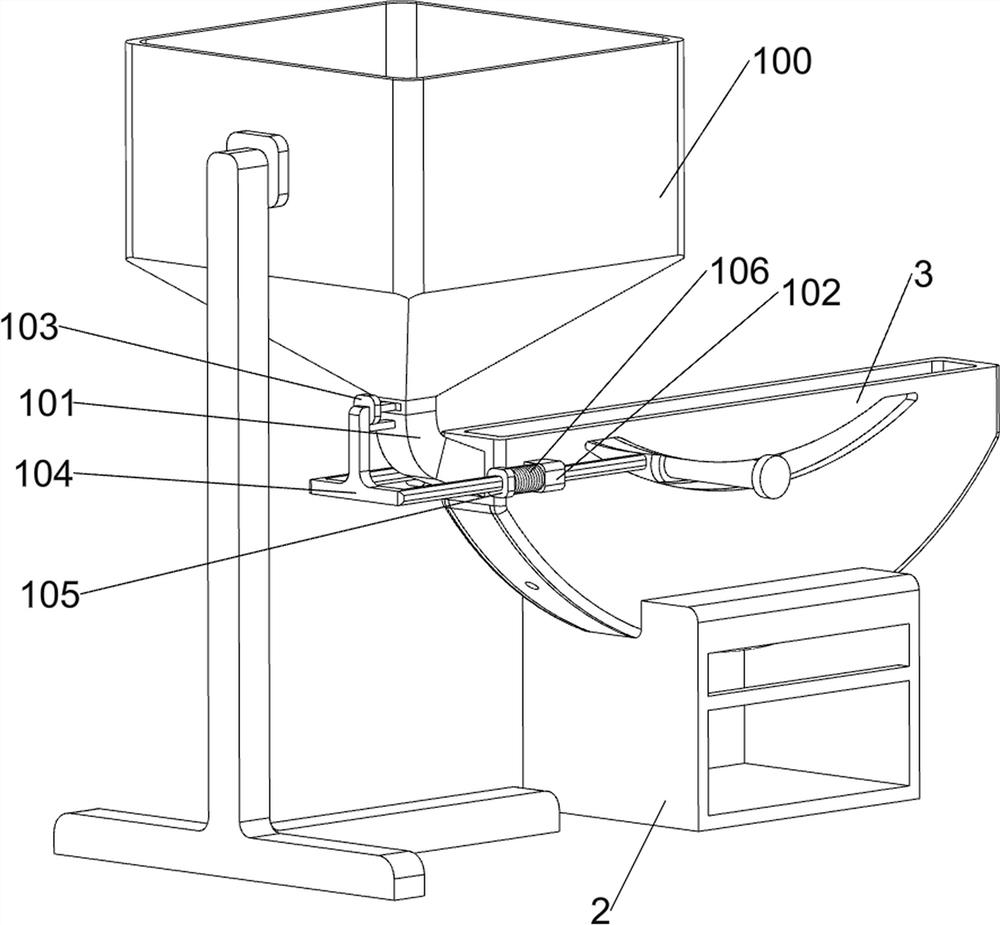

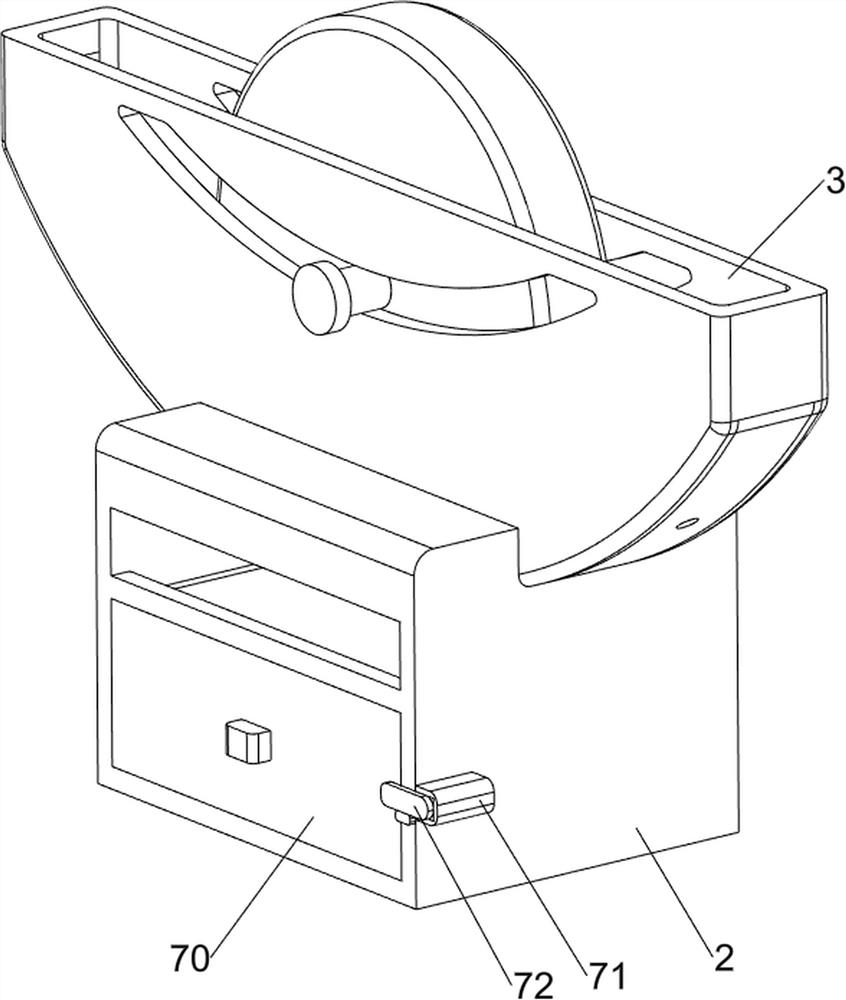

[0068] A kind of Chinese herbal medicine grinding device for bioengineering, such as figure 1 , figure 2 , image 3 and Figure 4As shown, it includes a base 1, a first mounting block 2, a second mounting block 3, a rotating shaft 4, a roller 5, a telescopic mechanism 6 and a charging mechanism 7, and the telescopic mechanism 6 includes a cylinder 60, a third mounting block 61, a first The slider 62 and the first connecting block 63, the top left side of the base 1 is provided with the first mounting block 2, the inner middle of the first mounting block 2 is provided with the second mounting block 3, and the upper part of the second mounting block 3 is slidingly provided with the rotating shaft 4 , the middle part of the rotating shaft 4 is provided with a roller 5, the roller 5 rotates in the second installation block 3, the top of the base 1 is provided with a telescopic mechanism 6, the first installation block 2 is provided with a charging mechanism 7, and the top right...

Embodiment 2

[0073] On the basis of Example 1, such as figure 1 , Figure 5 , Figure 6 , Figure 7 and Figure 8 As shown, a screening mechanism 8 is also included. The upper side of the first mounting block 2 is provided with a screening mechanism 8. The screening mechanism 8 includes a fifth mounting block 80, a third sliding block 81, a clamping block 82, a second spring 83, and a screen cloth. 84. The sixth mounting block 85 and the third connecting block 86, four fifth mounting blocks 80 are arranged on the upper part of the first mounting block 2, and the third sliding block 81 is provided on the outside of the fifth mounting block 80, and the third sliding block Block 81 inner side is all slidingly provided with clamping block 82, is provided with second spring 83 between clamping block 82 and the third similar sliding block 81, and first mounting block 2 upper inner sliding type is provided with screen cloth 84, and clamping block 82 and the fifth mounting block 80 and the scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com