A discontinuous graded gravel screening device and screening method thereof

A screening device and a technology for grading crushed stones, which are applied in chemical instruments and methods, screening, solid separation, etc., can solve problems such as affecting the screening effect and blocking the screen holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

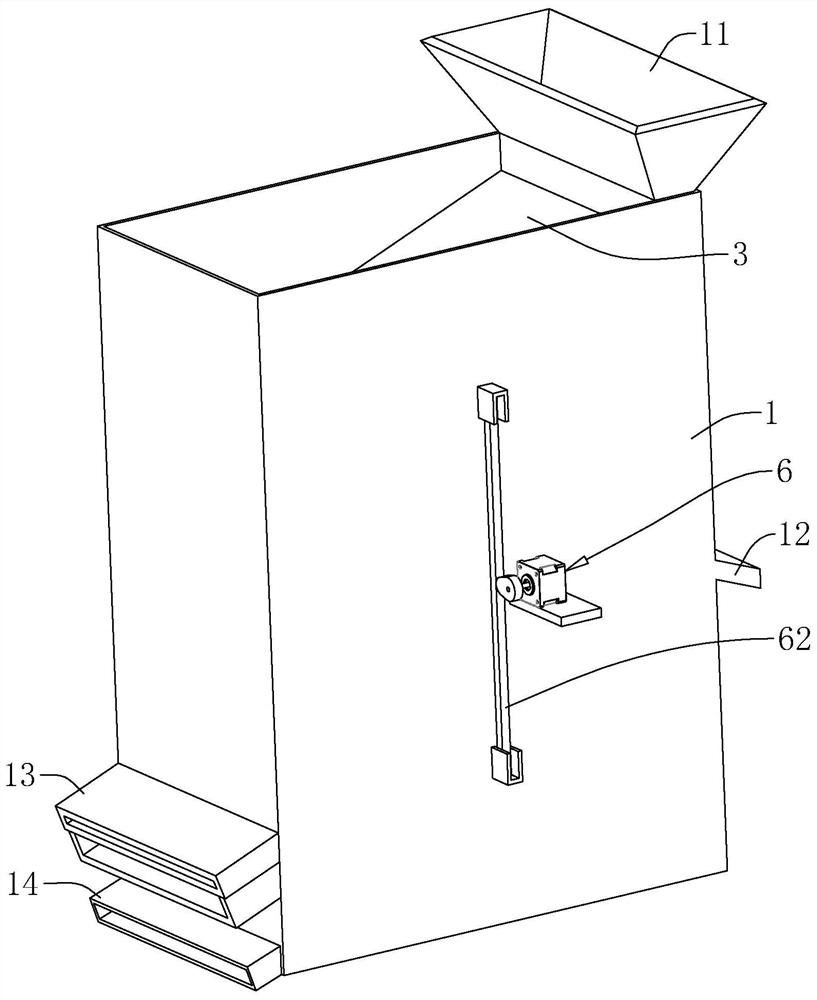

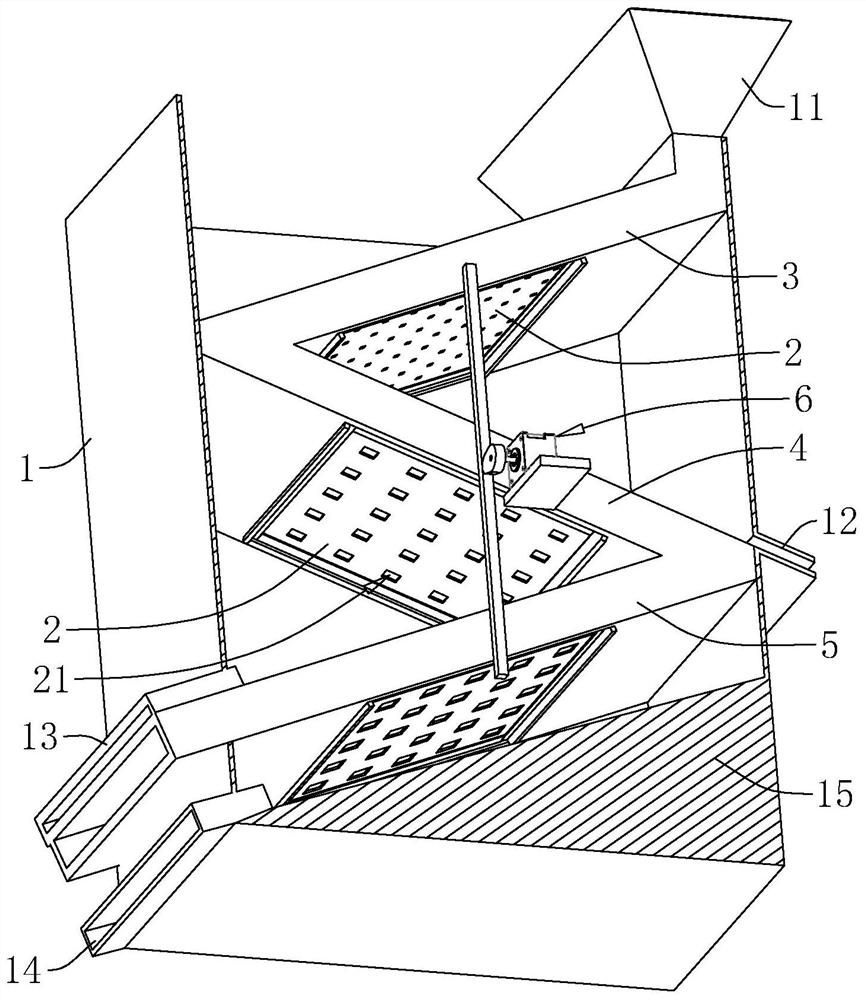

[0040] The application discloses a discontinuous grading gravel screening device. refer to figure 1 with figure 2 The discontinuous grading crushed stone screening device includes an installation frame 1 and a screen 2 arranged in the installation frame 1 for screening materials. The installation frame 1 is provided with a feeding bin 11 for placing materials. When screening, the material is placed in the upper bin 11, and enters the installation frame 1 to be screened through the screen 2.

[0041] refer to figure 1 with figure 2, a feeding plate 3 is arranged in the installation frame 1, the feeding plate 3 is a hollow structure and openings are opened at both ends, one end of the feeding plate 3 is arranged correspondingly to the upper silo 11, and the other end is arranged obliquely toward the ground The screening net 2 is arranged on the side of the feeding plate 3 close to the ground, and the screening net 2 is provided with a plurality of screening holes 21 for sc...

Embodiment 2

[0051] A screening method of a discontinuous grading gravel screening device comprises the following steps:

[0052] In the first step, the material is poured into the feeding bin 11, the material enters the feeding plate 3 through the feeding bin 11, and the material is screened through the screening net 2 in the feeding board 3;

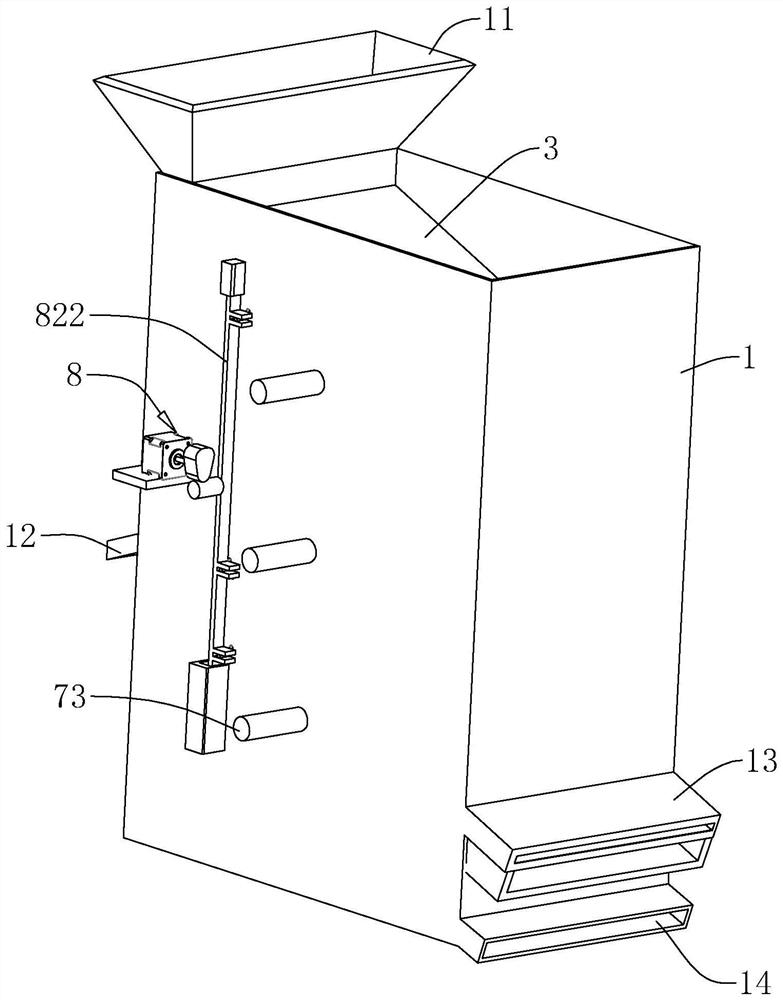

[0053] In the second step, the driving member 61 drives the screening net 2 to move in the installation frame 1 through the adjustment plate 62 and the adjustment rod 63, and at the same time reciprocates under the action of the reset component 7, thereby improving the screening effect on materials;

[0054] In the third step, the materials of different particles flow out of the installation frame 1 through the first discharge pipe 12 and the second discharge pipe 13, and the materials of different particle sizes are classified;

[0055] In the fourth part, the transmission member 821 drives the auxiliary sleeve 81 to rotate through the transmissio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com