Assembly type modular prefabricated composite floor slab pouring forming mold

A technology for laminating floors and forming molds, applied in the directions of molds, floors, forming surfaces, etc., can solve the problems of inconvenient pouring of laminated floors, unsuitable molds, affecting the yield rate of arc-shaped laminated floors, etc., to improve pouring efficiency and quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

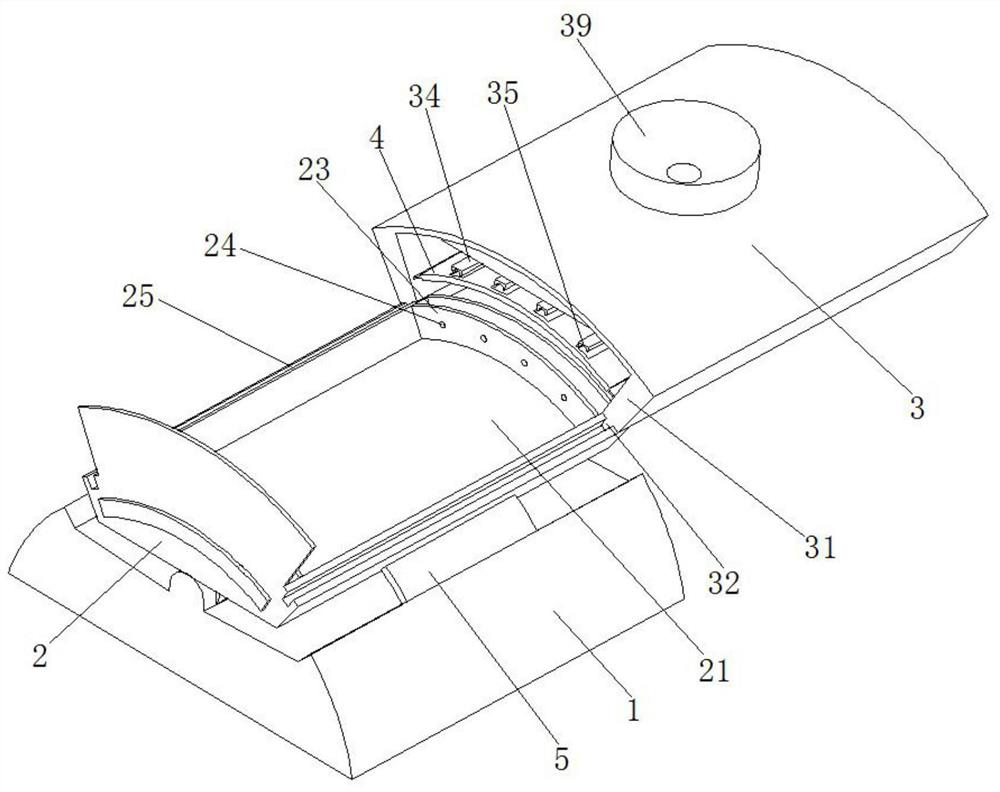

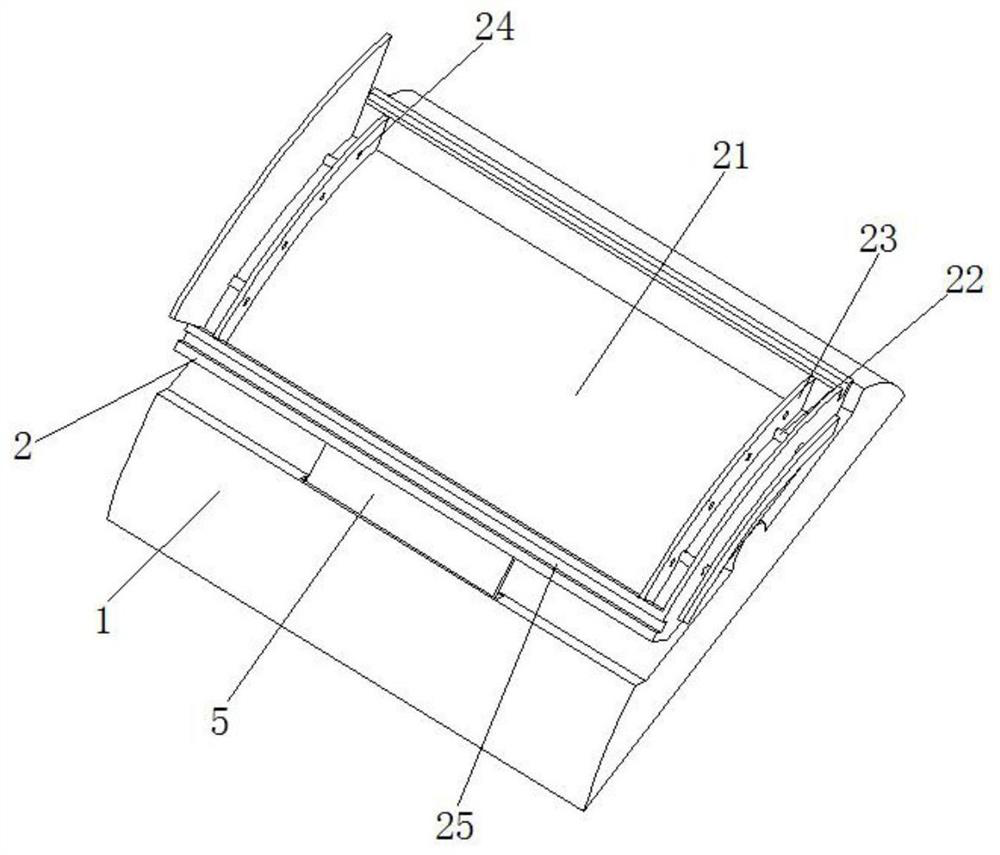

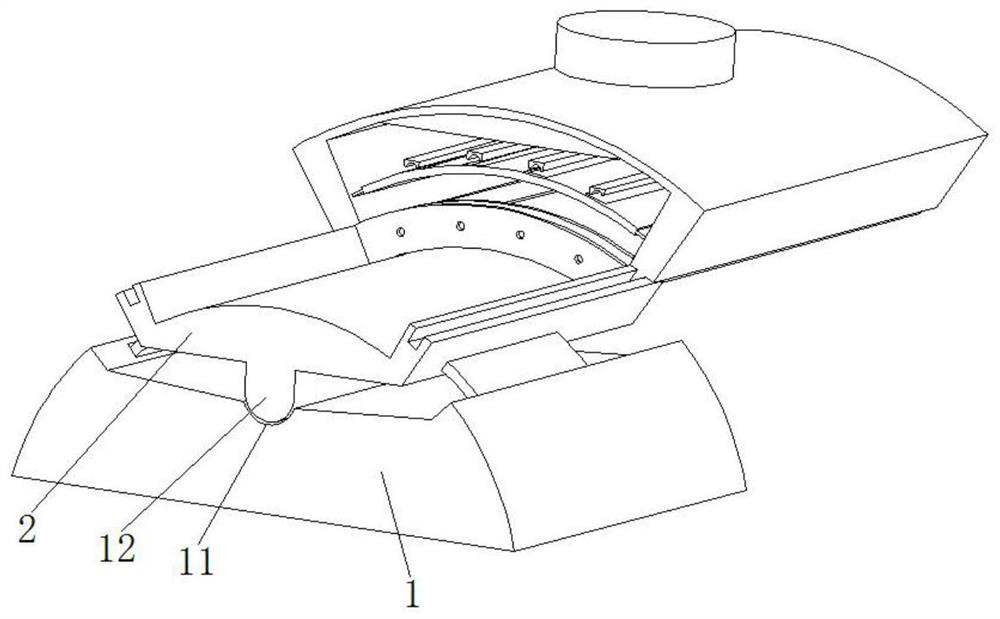

[0026] Such as Figure 1 to Figure 8 As shown, an assembled modular prefabricated laminated floor casting molding mold includes a base 1, the top of the base 1 is provided with a groove 11 with an arc-shaped structure, and a rotating base 12 is arranged in the groove 11, and the rotating base The top of the mold table 2 is provided with a mold table 2, and the top of the mold table 2 is provided with an arc-shaped mold cavity 21. Both ends of the mold table 2 are provided with a number of insertion rods 22, and one end of the insertion rod 22 extends through the mold table 2 to The ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap