Filtering device of butyronitrile glove hand mold cleaning tank

A filter device and nitrile glove technology, which is applied in the fields of filtration separation, household components, applications, etc., can solve the problems of equipment downtime, poor cleaning effect of hand molds in the cleaning tank, etc., and achieve the effect of ensuring the filtering effect and cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

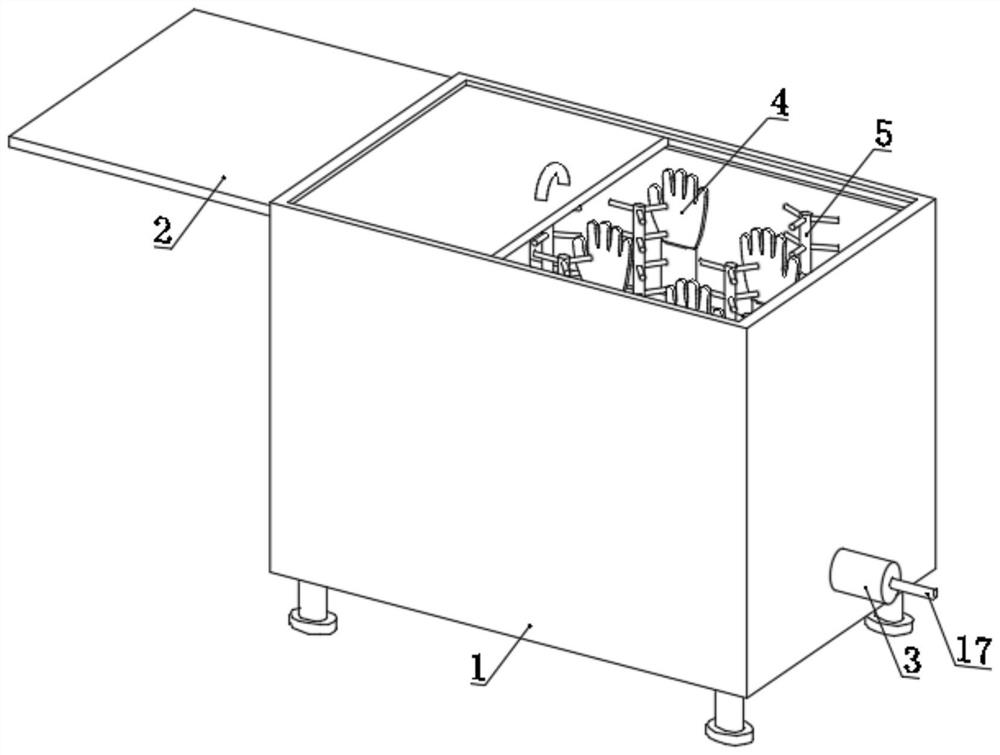

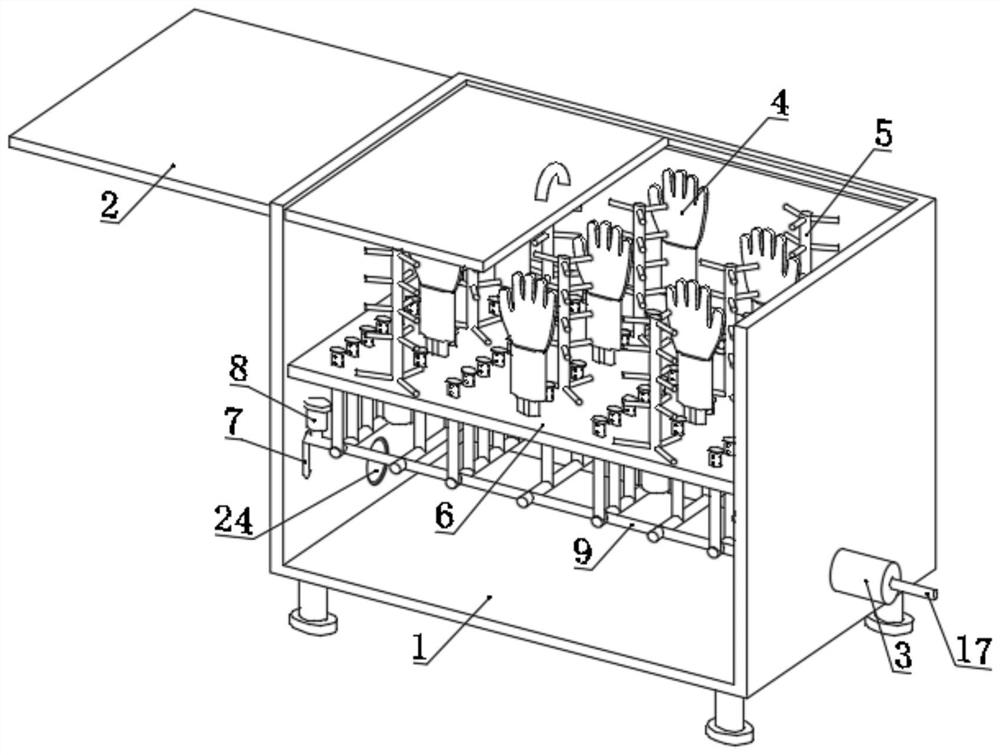

[0036] refer to Figure 1-7 , a nitrile glove hand mold cleaning tank filter device, a nitrile glove hand mold cleaning tank filter device, comprising a box 1, the upper part of the box body 1 is slidingly installed with a box cover 2, and the inside of the box body 1 top is provided with A horizontal chute matched with the side of the case cover 2, a handle is installed on the top wall of one end of the case cover 2.

[0037] The box cover 2 can be opened and closed by the handle, and the handle is installed on figure 1 The top wall on the right side of the box cover 2 shown in , the handle can also prevent the box cover 2 from falling off with the box body 1.

[0038] One side of casing 1 bottom is equipped with water pump 3, and the other side of casing 1 bottom is equipped with blowdown pipe 24, and the water inlet end of water pump 3 is equipped with water outlet hose 18, and water outlet hose 18 adopts rubber hose. A water inlet pipe 17 is installed at the water outlet...

Embodiment 2

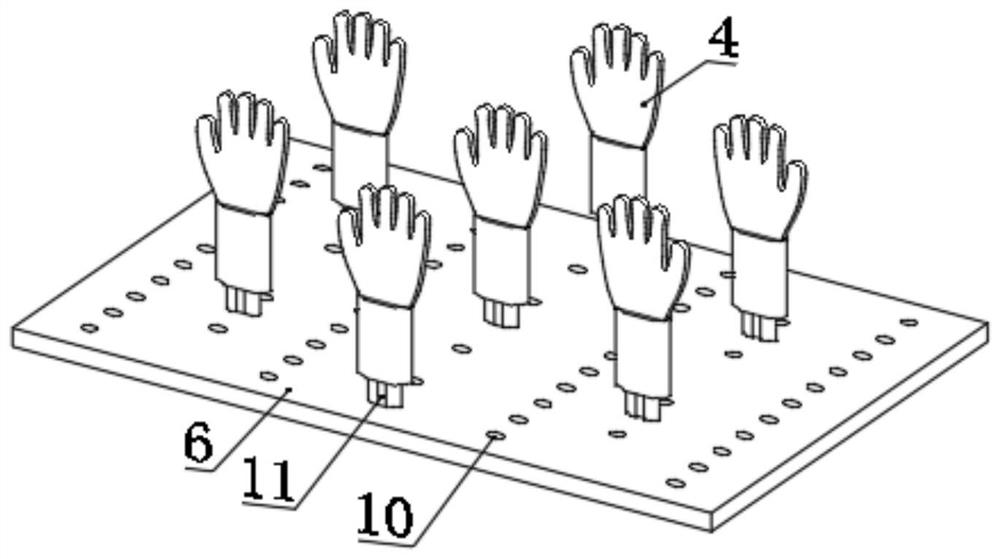

[0051] Present embodiment two is on the basis of embodiment one, by being fixed with rubber sheet 23 at the top of standpipe 21, the diameter of rubber sheet 23 is greater than the inner diameter of through hole 10, and the inner diameter of through hole 10 is 2cm, and the diameter of rubber sheet 23 2.5 cm, the rubber sheet 23 is in frictional contact with the inner wall of the through hole 10 .

[0052] When the top of the standpipe 21 moves up and down in the through hole 10, the rubber sheet 23 at the top can utilize its own elasticity to be squeezed and gradually enter the through hole 10, and the rubber sheet 23 and the inner wall of the through hole 10 friction effect, further increase the cleaning effect on the through hole 10, and when the top of the standpipe 21 stops moving in the through hole 10, the rubber sheet 23 can also increase the blocking effect on the through hole 10, thereby ensuring that the box body 1 The upper body of water will not flow out under abno...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com