A special self-locking spreader for steel structure

A steel structure and spreader technology, applied in the direction of load hanging components, transportation and packaging, etc., can solve the problems of reducing risks, achieve the effects of reducing risks, simple operation, and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

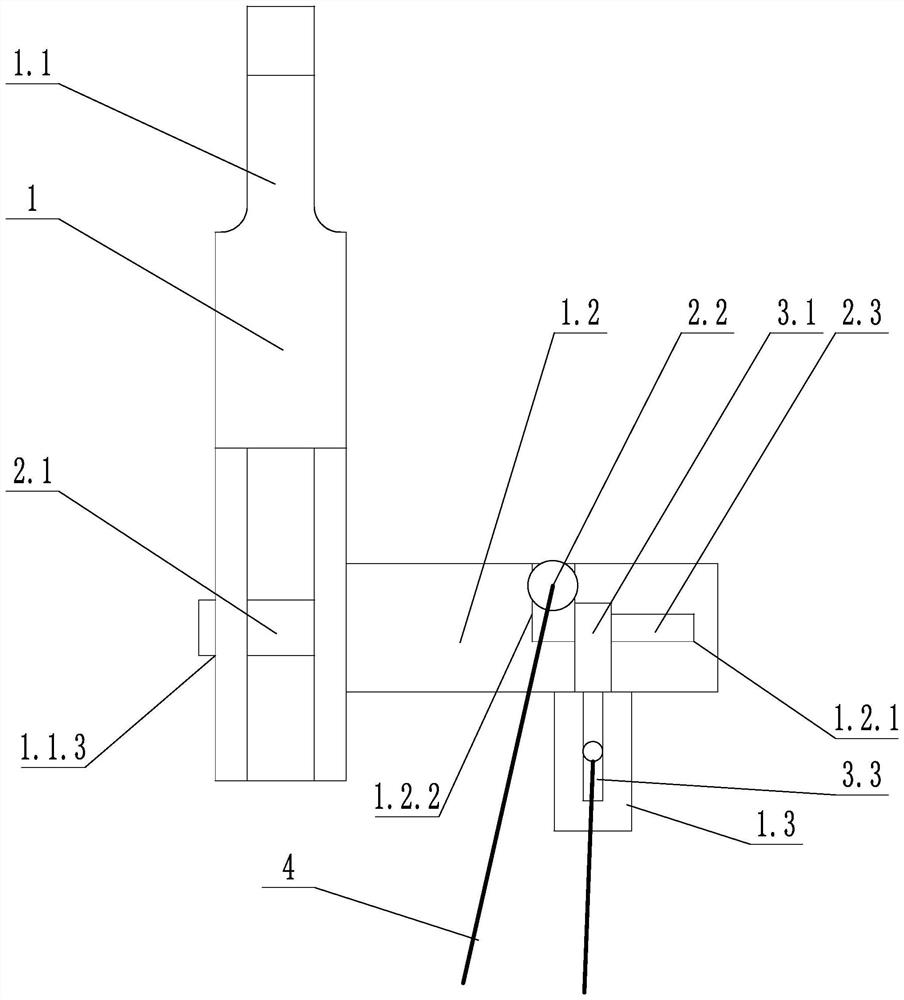

[0031] like image 3 As shown, a special self-locking spreader for steel structures includes a spreader body 1, a fixing structure 2, a locking structure 3 and a pull rope 4. The spreader body 1 includes a connecting block 1.1, a first sleeve 1.2 and a second set of Pipe 1.3, the axis of the first sleeve 1.2 is perpendicular to the axis of the second sleeve 1.3, the connecting block 1.1 is provided with a jack 1.1.3, the jack 1.1.3 transversely passes through the connecting groove 1.1.2, the first sleeve 1.2 The side wall is provided with a first sliding groove 1.2.1 and a first locking groove 1.2.2 that communicate with each other.

[0032] The fixed structure 2 includes a fixed pin 2.1, a first pull rod 2.2 and a first telescopic spring 2.3. The fixed pin 2.1 is arranged in the first sleeve 1.2 and is slidably connected with the first sleeve 1.2. The fixed pin 2.1 can be along the first sleeve 1.2. The axis rotates, one end of the fixed pin 2.1 passes through the jack 1.1.3...

Embodiment 2

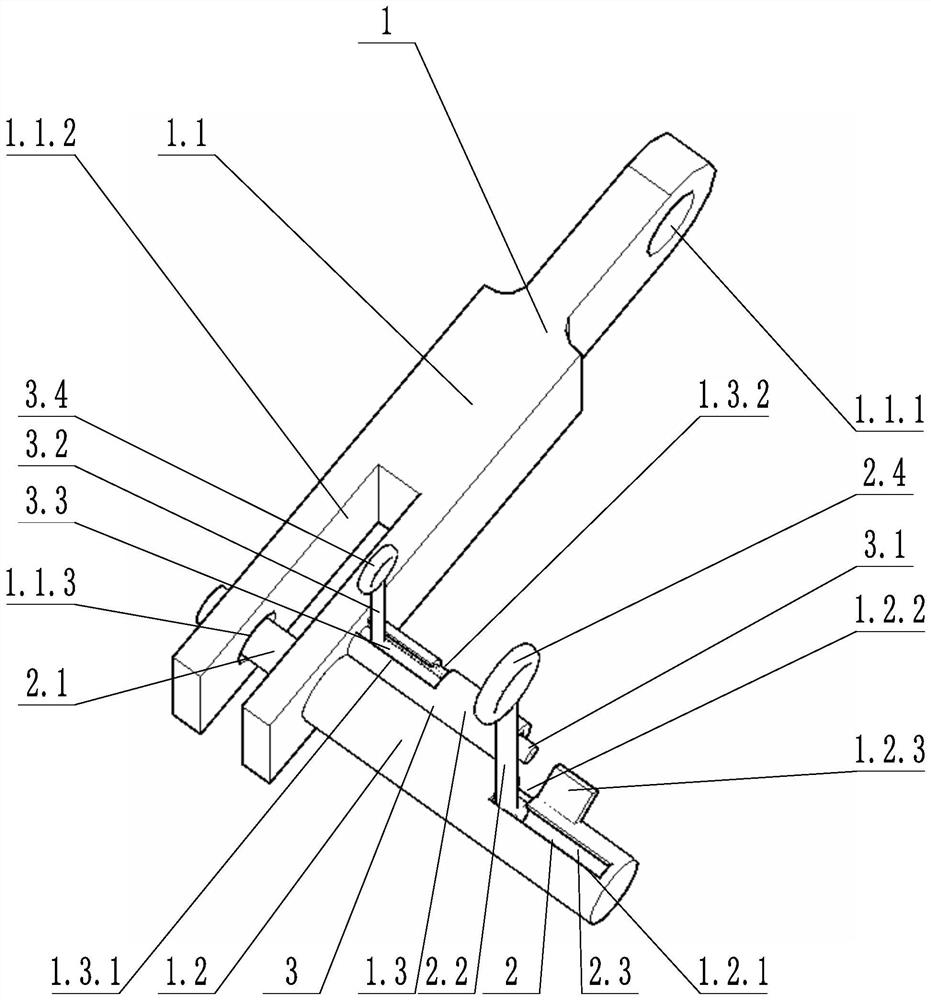

[0036] like figure 1 As shown, a special self-locking spreader for steel structures includes a spreader body 1, a fixing structure 2, a locking structure 3 and a pull rope 4. The spreader body 1 includes a connecting block 1.1, a first sleeve 1.2 and a second set of Pipe 1.3, the connecting block 1.1 is provided with a jack 1.1.3, a connecting hole 1.1.1 and a connecting groove 1.1.2, the jack 1.1.3 transversely passes through the connecting groove 1.1.2, on the side wall of the first sleeve 1.2 A first chute 1.2.1 and a first lock slot 1.2.2 communicated with each other are provided; the side wall of the second sleeve 1.3 is provided with a second chute 1.3.1 and a second lock slot 1.3.2 communicated with each other .

[0037] The fixed structure 2 includes a fixed pin 2.1, a first pull rod 2.2 and a first telescopic spring 2.3. The fixed pin 2.1 is arranged in the first sleeve 1.2 and is slidably connected with the first sleeve 1.2. The fixed pin 2.1 can be along the first ...

Embodiment 3

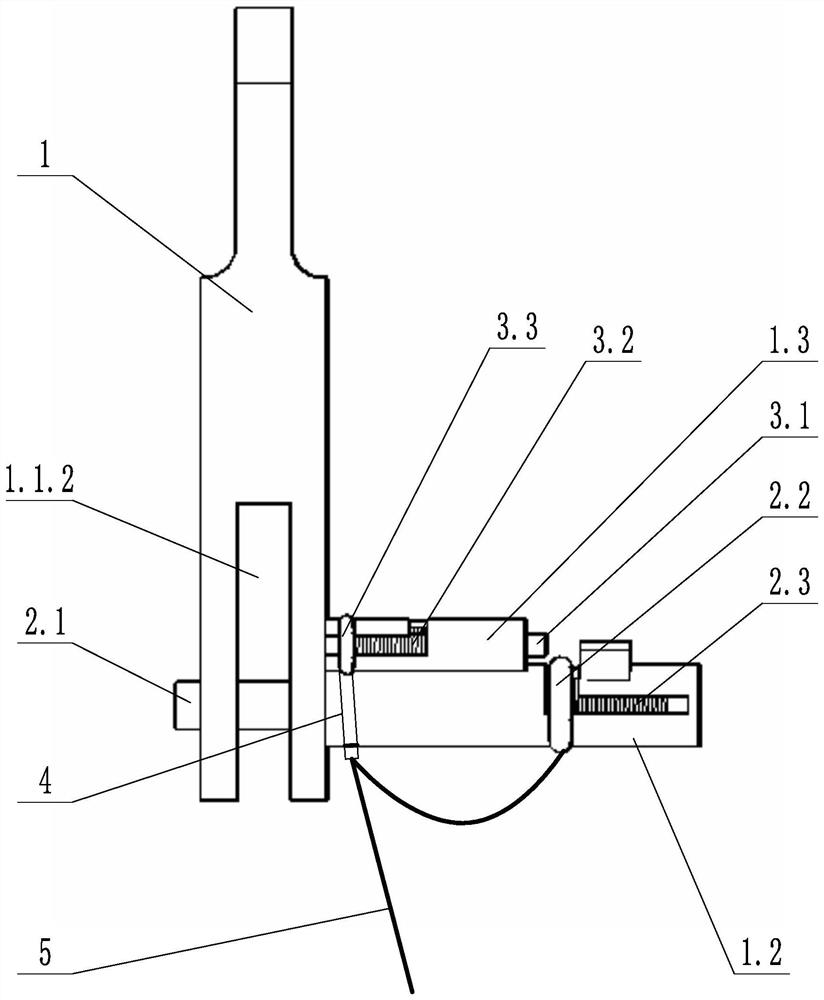

[0041] like figure 1 and figure 2 As shown, on the basis of Embodiment 2, the first pull rod 2.2 and the second pull rod 3.2 are connected to the same pull rope 4; the second pull rod 3.2 is provided with an elastic elastic member 5, one end of the elastic elastic member 5 is connected to the second pull rod 5. The pull rod 3.2 is connected, and one end of the pull rope 4 is fixed with the elastic telescopic element 5 and then passes through the elastic telescopic element 5 and is connected to the first pull rod 2.2.

[0042] In the above technical solution, the elastic elastic member 5 may be a retractable spring or an elastic elastic cord or other elastic member. One end of the pull rope 4 is bound to the first pull rod 2.2, and after leaving an appropriate margin, it is knotted and then tied to the elastic telescopic element 5 on the second pull rod 3.2. The function of the elastic telescopic element 5 is to adjust the length of the rope between the two pull rods, and to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com