Heat affected zone control device for high-frequency tempering equipment

A heat-affected zone and control device technology, applied in the mechanical field, can solve problems such as unstable control of the heat-affected zone, achieve balanced cooling effects, achieve stable control, and improve mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

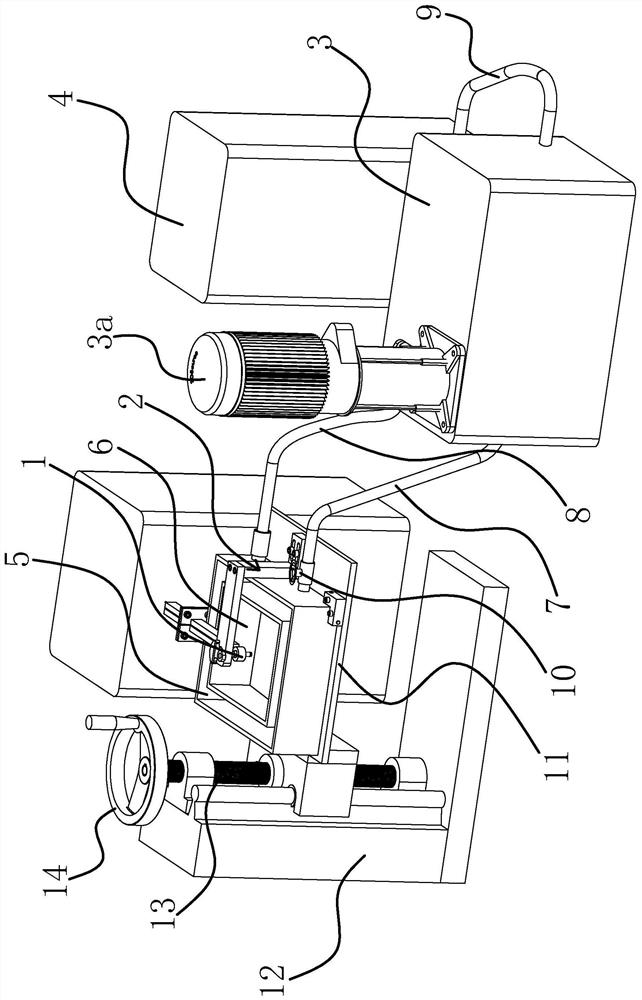

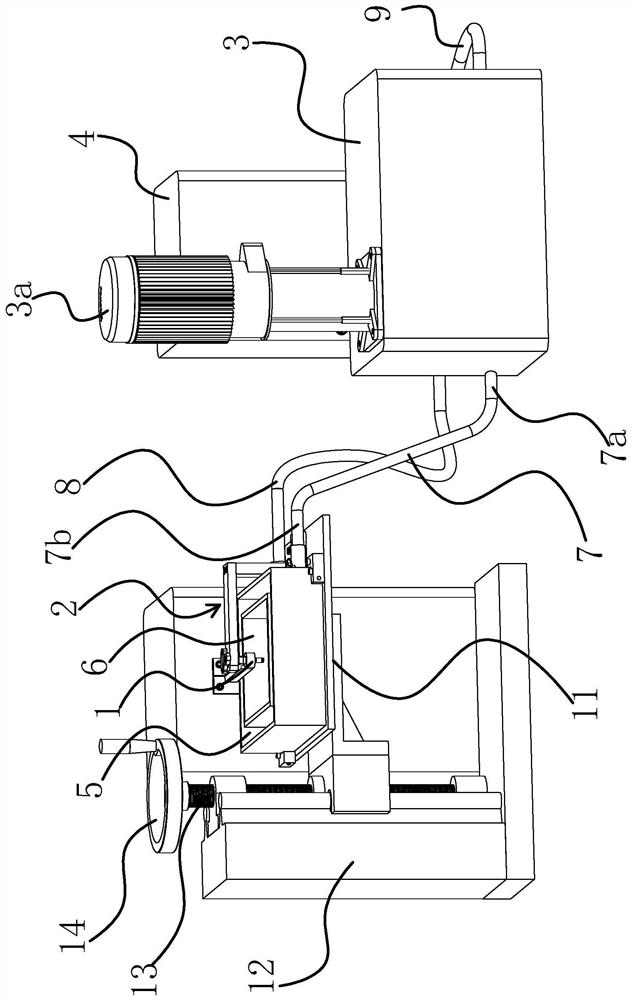

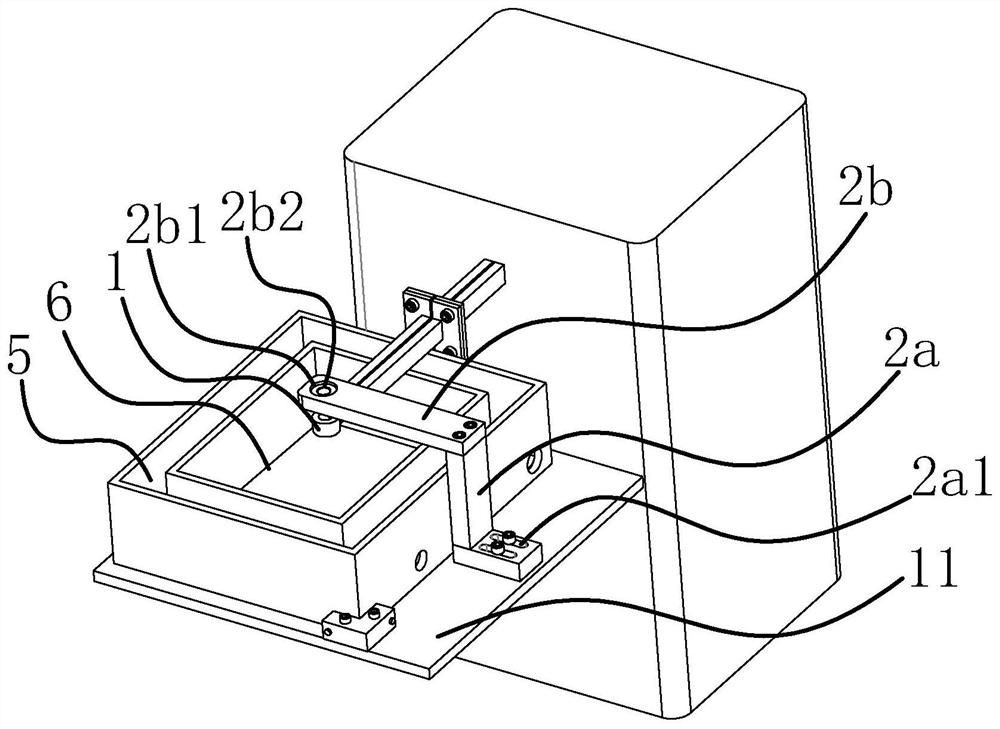

[0034] like figure 1 and figure 2As described above, the heat-affected zone control device used for high-frequency tempering equipment, the high-frequency tempering equipment includes a high-frequency induction coil 1 and a fixture 2, and the heat-affected zone control device includes a cooling liquid supply box 3, a liquid cooler 4, The overflow tank body 5 and the cooling tank body 6 located inside the overflow tank body 5, the cooling tank body 6 is located below the high-frequency induction coil 1, the clamp 2 is located above the high-frequency induction coil 1, the cooling liquid supply tank 3 and the cooling tank body 6 is connected with a medium inlet pipe 7, a return pipe 8 is connected between the liquid cooler 4 and the overflow tank body 5, and a medium pipe 9 is connected between the cooling liquid supply tank 3 and the liquid cooler 4. Specifically, the liquid cooler 4 adopts a water chiller model RHP-AD, and a water pump 3a is also arranged in the cooling liqu...

Embodiment 2

[0043] The structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that in this embodiment, the clamp 2 is located in the cooling tank 6, specifically, the clamp 2 is a three-piece set in the cooling tank 6 Jaw Chuck. Usually, the heat-affected part on the part is divided into two ends. When controlling the accuracy of the heat-affected zone at the upward end of the part, the upward end of the part is clamped by the three-jaw chuck, and the end is immersed in the cooling liquid, so as to complete the heat-affected part on the upward end. The precision control of the heat-affected zone realizes the function that the device can control the precision of the heat-affected zone at both ends of the part.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com