Non-floor dynamic height-adjusting support and construction method for steel plate composite girder bridge deck construction

A technology of composite beams and steel plates, which is applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of inability to adjust dynamically and in real time, and inconvenient erection of floor supports, so as to achieve easy control of construction quality, easy operation of adjustment and dismantling, and The effect of simple construction technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

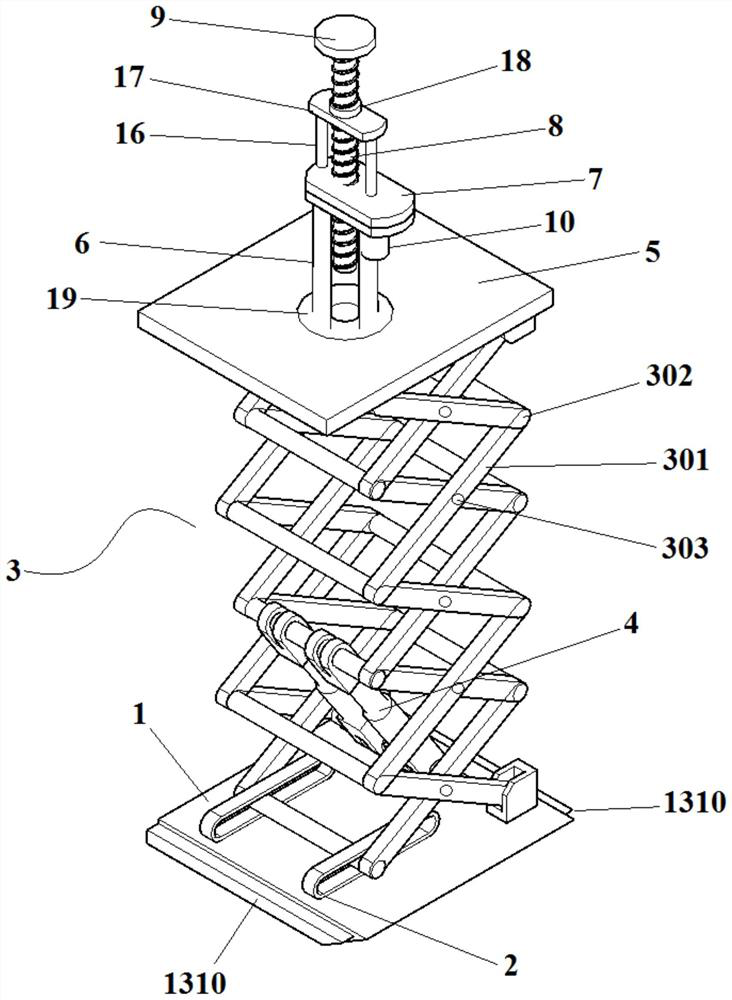

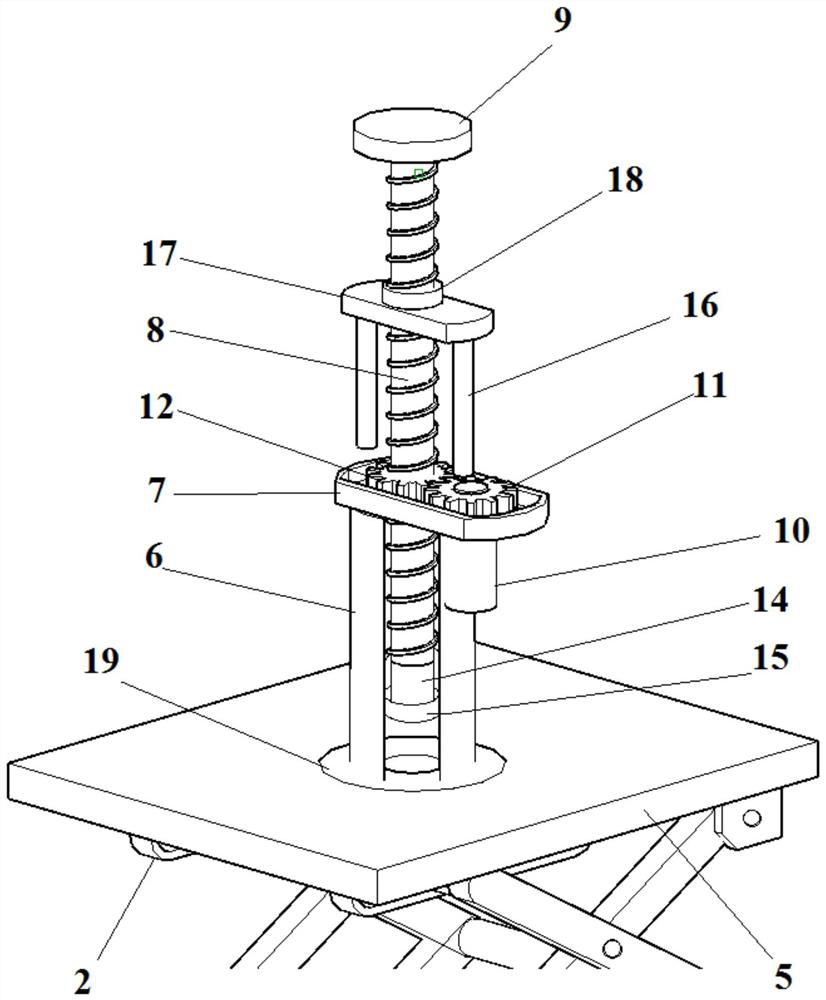

[0042] This embodiment provides a non-floor dynamic height-adjusting bracket for the construction of steel plate composite girder bridge deck, such as Figure 1 to Figure 3As shown, including the lower platform 1 for linkage work, the lower platform 1 for linkage work is fixedly provided with a scissor bar restraint rail 2, and the scissor bar restraint rail 2 is installed with a scissor bar lift that can move in the scissor bar restraint rail 2 One end of the bottom of the assembly 3, the other end of the bottom of the scissor lift assembly 3 is hinged on the lower platform 1 for linkage work; the lower platform 1 for linkage work is also installed with the tail end of the electro-hydraulic telescopic rod 4, and the head of the electro-hydraulic telescopic rod 4 The end is connected to the scissor bar lifting assembly 3 to drive the lifting and lowering of the scissor bar lifting assembly 3; the top end of the scissor bar lifting assembly 3 is installed in the scissor bar rest...

Embodiment 2

[0057] The present embodiment provides a construction method for a steel plate composite girder bridge deck that does not fall to the ground, and the method adopts the non-falling dynamic height-adjusting bracket for the construction of a steel plate composite girder bridge deck in Example 1;

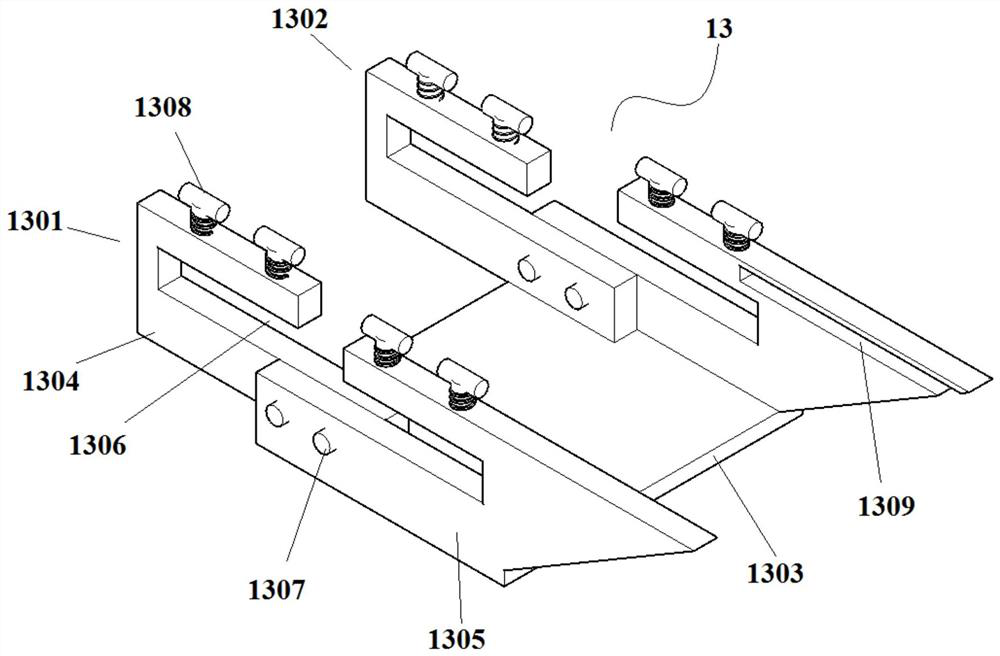

[0058] like Figure 4 and Figure 5 As shown, on the I-beam 20 of the steel plate composite beam 21, a plurality of non-floor dynamic height-adjusting brackets are installed for the construction of the steel plate composite beam bridge deck, and the linkage work at the bottom of the non-floor dynamic height-adjusting bracket for the construction of each steel plate composite girder bridge deck is used. The lower platform 1 is installed on the wing plates on both sides of the I-beam 20 of the steel plate composite beam 21 through the I-beam fasteners 13, and the formwork pedestal 9 on the top of the non-floor dynamic height-adjusting bracket is used for the construction of each steel pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com