Aluminum alloy profile

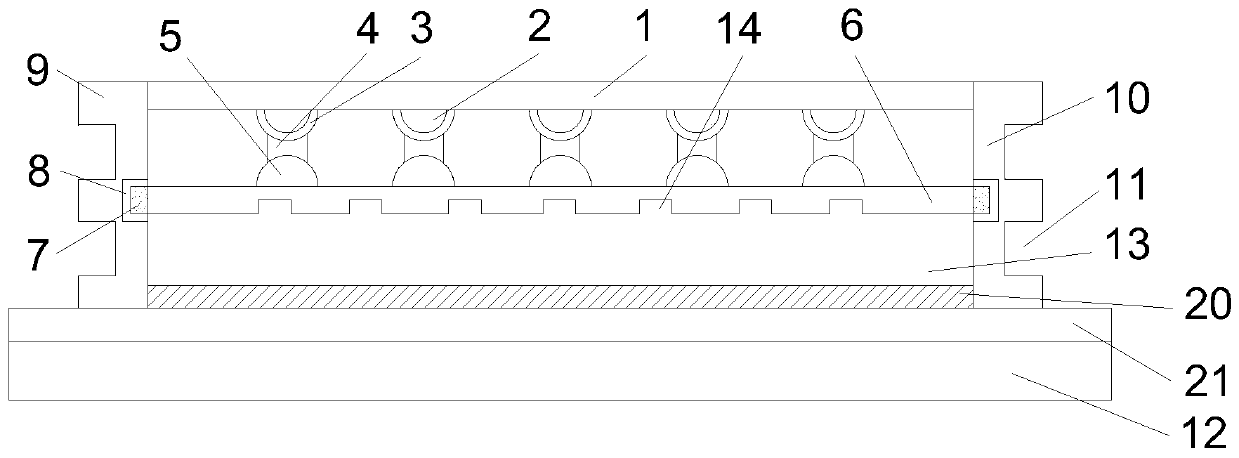

A technology of aluminum alloy profiles and profiles, applied in railway car body parts, static electricity, railway car body and other directions, can solve the problems of inability to obtain a train floor, easy deformation of aluminum alloy profiles, insufficient track strength, etc., to prevent distortion and deformation. , The effect of strong bonding, enhanced support strength and compressive ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

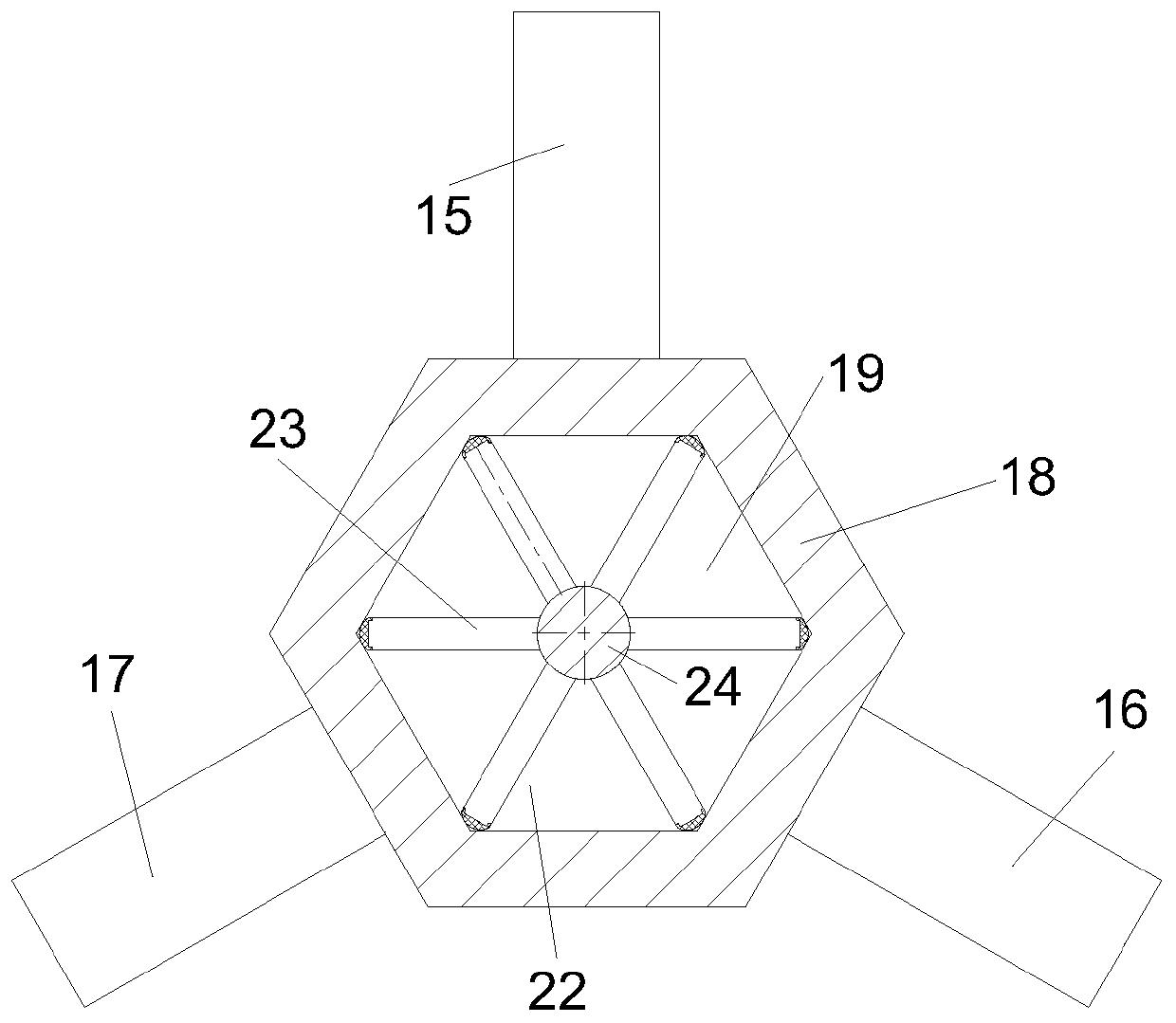

[0024] As an embodiment of the present invention, a support member 22 is slidably installed in the cavity 19, and the support member 22 includes a fixed plate 23 and a fixed shaft 24; five fixed plates 23 are provided; One end of 23 is welded on the outer surface of the fixed shaft 24 and is distributed in five equal parts; the supporting member can be inserted into the cavity 19 to support the regular hexagonal compression body 18 . During work, by sliding and inserting the corresponding support piece 22 into the cavity 19 in the regular hexagonal pressure-resistant body 18, when the profile is subjected to external pressure, the internal support piece 22 can effectively support the cavity 19. Strong support is provided to ensure the support strength of the regular hexagonal compression body 18, prolong the overall service life of the regular hexagonal compression body 18, and further enhance the overall support strength and compressive capacity of the profile.

[0025] As an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com