A super high-rise structure with indented bottom, inner circle and outer square double-tube oblique grid and its composition method

A super-high-rise, oblique technology, applied in the direction of special structures, building components, building structures, etc., can solve the problems of complex component composition, complex node connection structure, etc., and achieve beautiful shape, guaranteed load-bearing performance, and high lateral resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

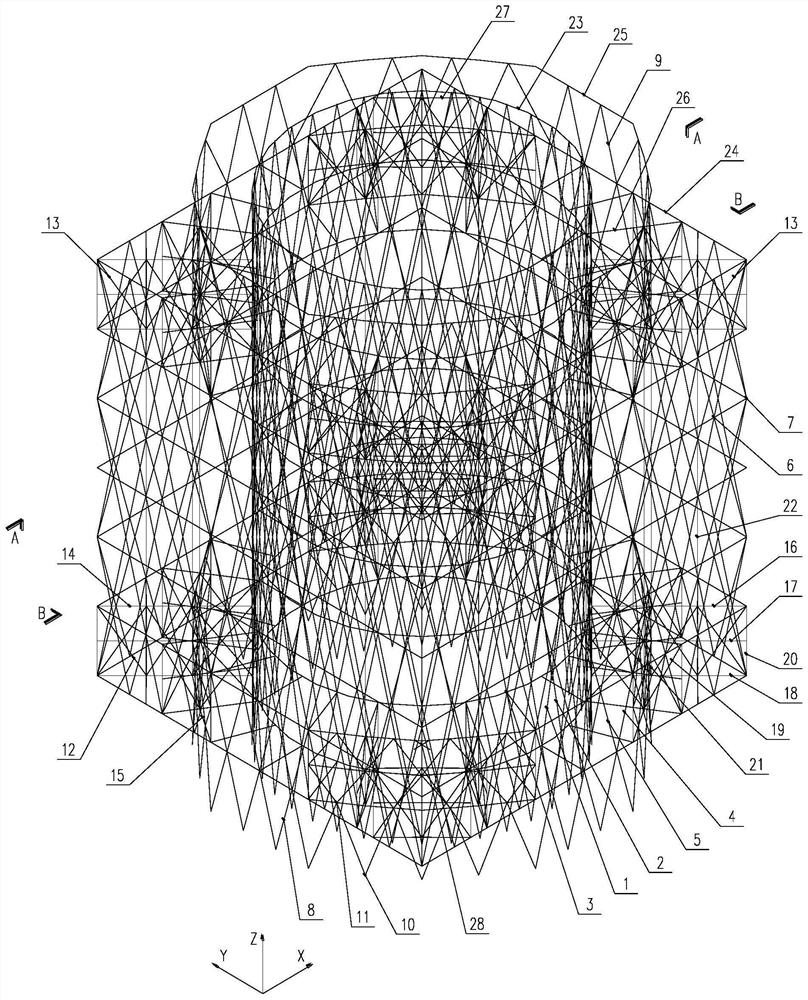

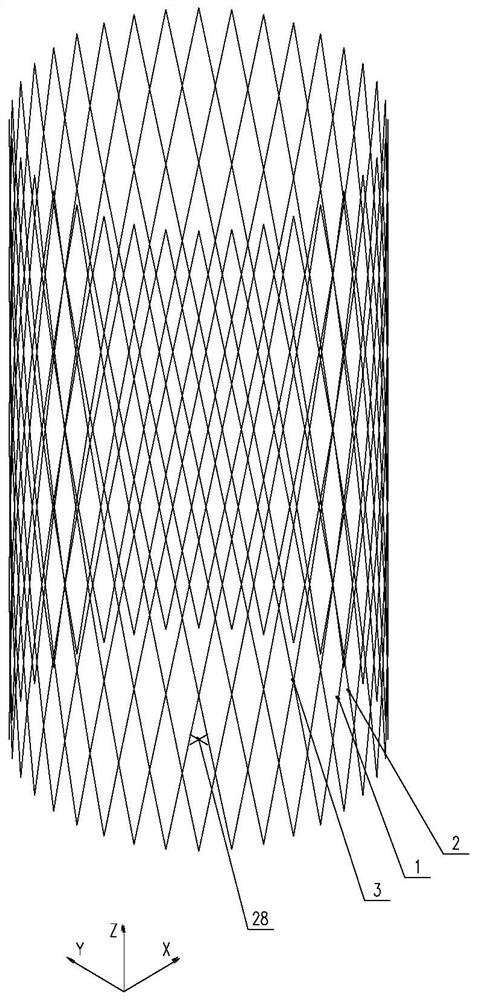

[0059] Such as Figures 1a-1g as well as Figure 2-Figure 4 As shown, the super high-rise structure with outer circle and inner square oblique grid with indented bottom, including inner circular through-height oblique cylinder, outer non-floor oblique cylinder, outer ring indented oblique column, and multi-layered corners Cantilever trusses, non-floor frame columns, floor steel beams. The inner round through-high oblique tube ( Figure 1b ) is located inside the overall structure, and is cross-connected by two-way slanted column members and set at full height to form a plane circular vertical slanted grid inner cylinder; the outer non-grounded slanted cylinder ( Figure 1c ) is located on the outer side of the overall structure, and is cross-connected by two-way slanted column members instead of being set on the ground, forming a plane rectangular vertical oblique grid outer cylinder, an inner round through-high oblique cylinder and an outer non-ground oblique cylinder to for...

Embodiment 2

[0077] Such as Figure 10 As shown, the specific components of the super high-rise structure of the inner circle and outer square double-barreled oblique grid structure with the bottom indented are as follows:

[0078] S1. The one-way oblique column 1 of the inner circular through-height oblique tube and the two-way oblique column 2 of the inner circular through-high oblique tube are cross-connected and set at the same height. The intersection is the arc oblique node 3 of the inner circular through-high oblique tube. Based on the central positioning point 28, the symmetrical inner ring is arranged to form a vertical oblique grid inner cylinder with a circular plane on the inner side;

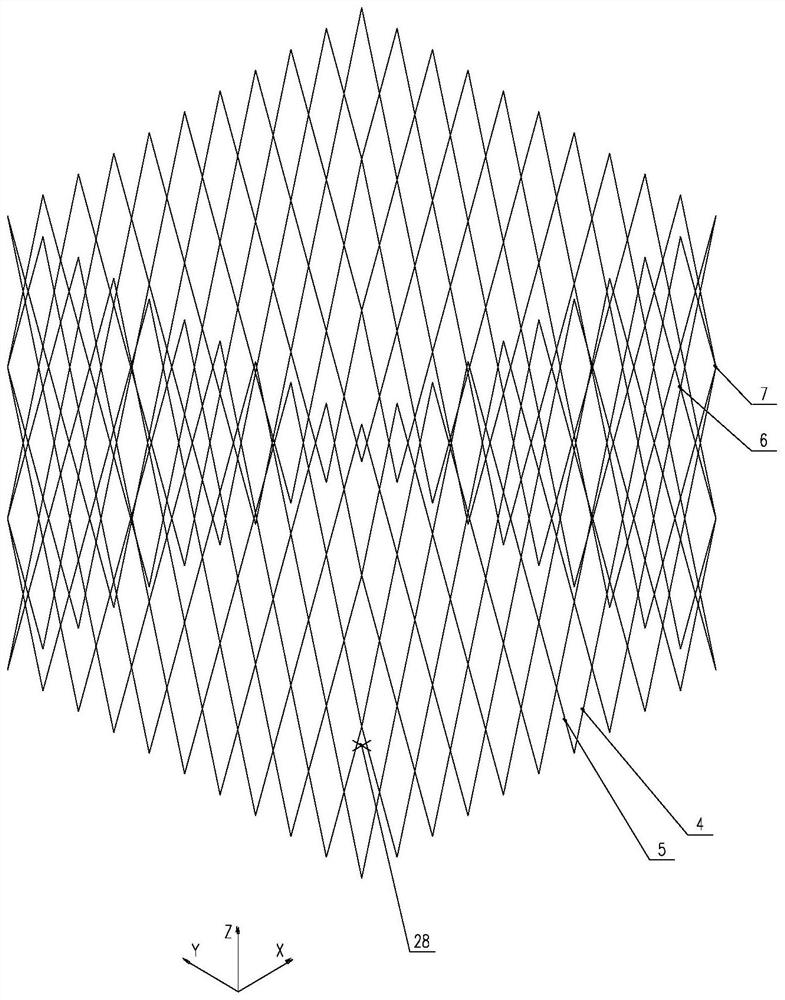

[0079] S2. The cross connection of the one-way inclined column 4 of the outer non-floor oblique tube and the two-way oblique column 5 of the outer non-ground oblique tube is not set on the ground, and the middle and corner intersections of the outer non-floor oblique tube are respectively The X...

Embodiment 3

[0089] The present invention also provides a super high-rise structure with inner circle, outer square, double-tube oblique grid structure with indented bottom, large cantilever indentation at the bottom and a high atrium inside. In the application of load bearing, the super high-rise means that the height of the structure is not less than 100 meters, and the indentation at the bottom means that the maximum cantilever indentation span at the bottom is not less than 20 meters.

[0090] Compared with the deficiencies of the prior art, the present invention provides a bottom-indented inner circle and outer square double-tube oblique grid super high-rise structure based on the double-sided inner circular high-slanted tube and the outer non-floor diagonal tube. The overall structural form of the tube oblique super high-rise, through the outer ring indented slanted columns and corner multi-layer cantilevered trusses, the vertical component conversion of the bottom large cantilever in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com