Ready-to-disassemble and ready-to-assemble connecting structure for headboard and bedstead

A technology of connecting structure and headboard, which is applied in the direction of connecting components, furniture connection, mechanical equipment, etc., can solve the problems of inconvenient disassembly and assembly, complex connection structure, non-removable fixed connection, etc., and achieve the effect of convenient disassembly and assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

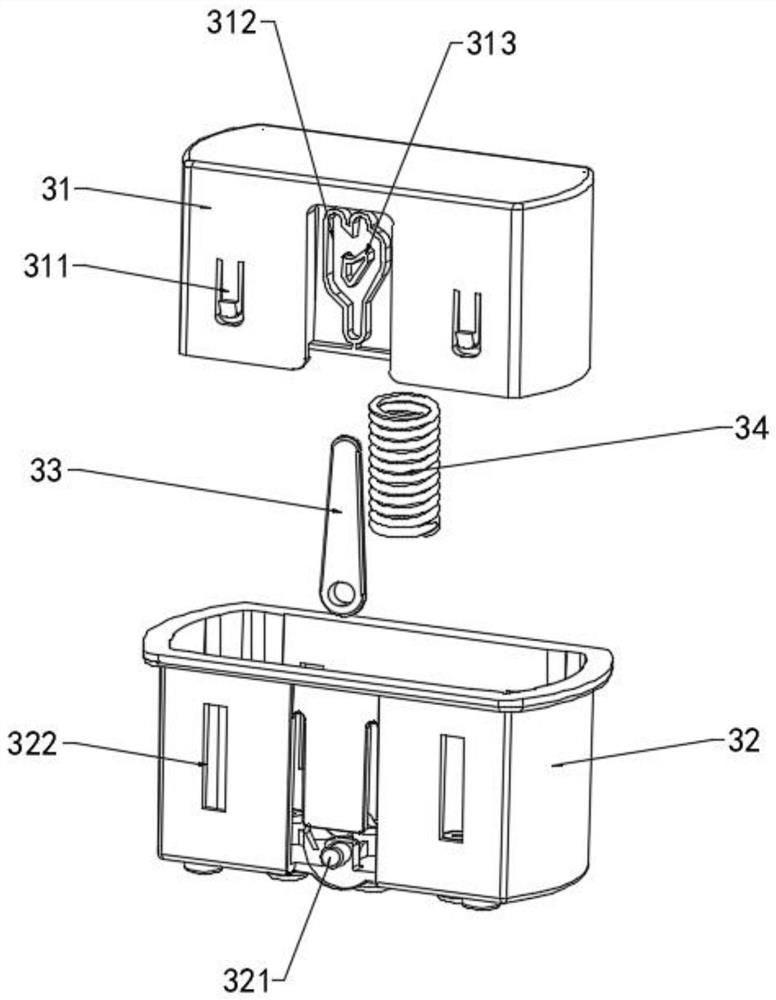

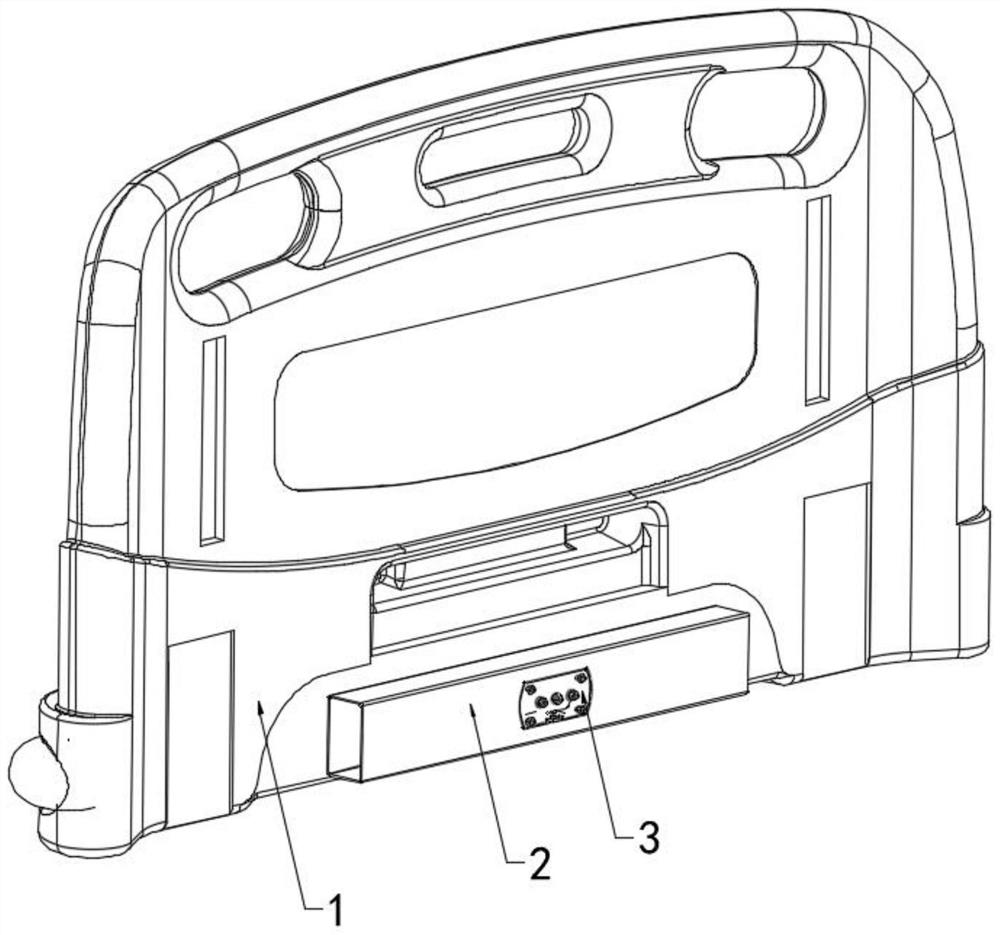

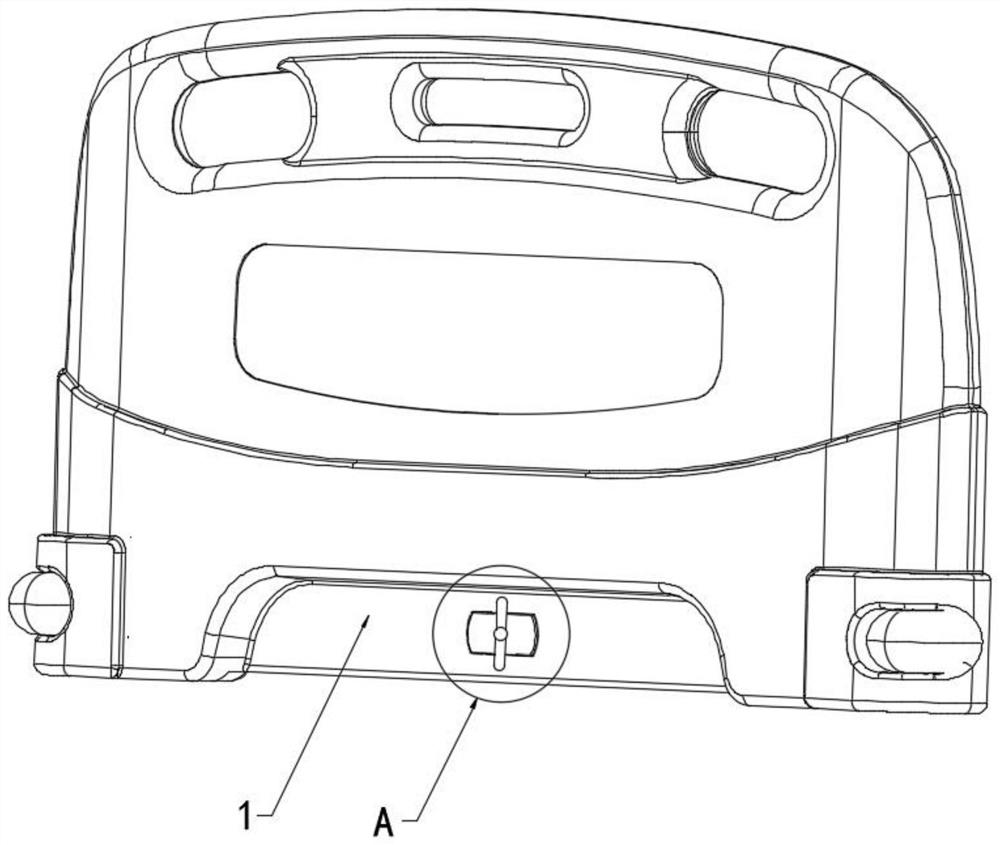

[0045] see Figure 1-12 , the present invention provides a technical solution: a detachable and ready-to-install connection structure for the headboard and the bed frame, including the headboard 1 and the bed frame 2, the headboard 1 and the bed frame 2 are connected by The mechanism 3 is connected, and the connecting mechanism 3 includes a connecting piece 32 fixedly connected to the middle part of the bed frame 2. The inside of the connecting piece 32 is sleeved with a pressing piece 31 passing through the headboard 1, and the two sides of the connecting piece 32 are provided with card slots 322. Both sides of the piece 31 are provided with buckles 311 connected to the slots 322, one side of the connecting piece 32 is rotatably connected with a connecting rod 33, one side of the bottom of the connecting piece 32 is provided with a boss 321, and the bottom of the connecting rod 33 has a The through hole 331 on the outside of the boss 321, the top side of the linkage rod 33 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com