Rotating shaft mechanism and electronic equipment

A technology of electronic equipment and rotating shaft, which is applied in the field of electronic equipment, can solve the problems of inconvenient adjustment operation and unsatisfactory adjustment results, and achieve the effect of preventing free fall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

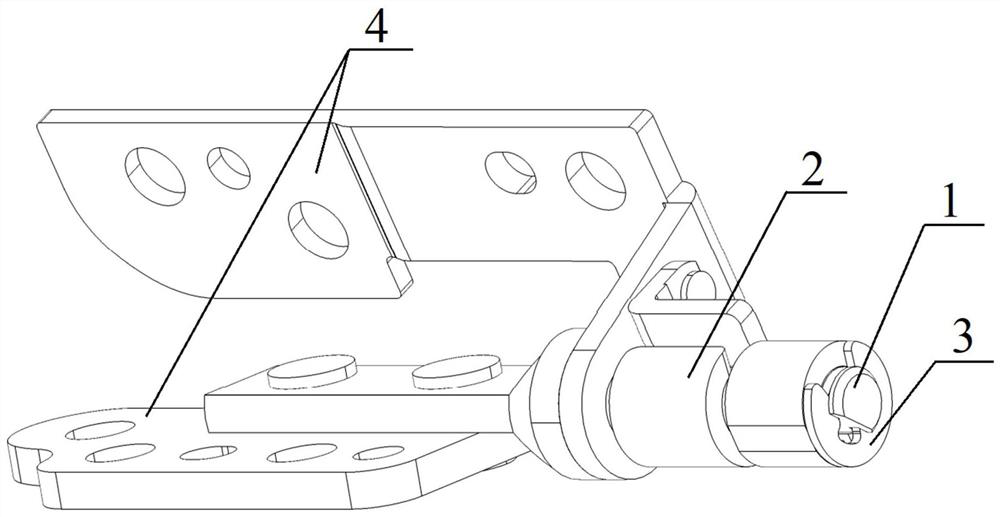

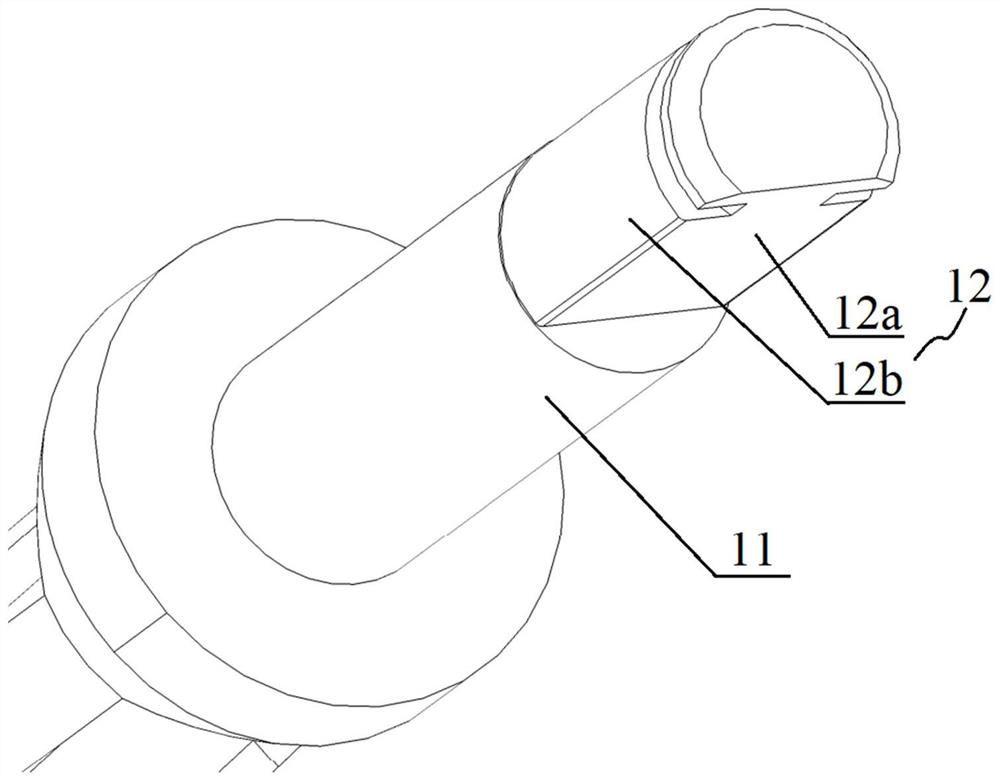

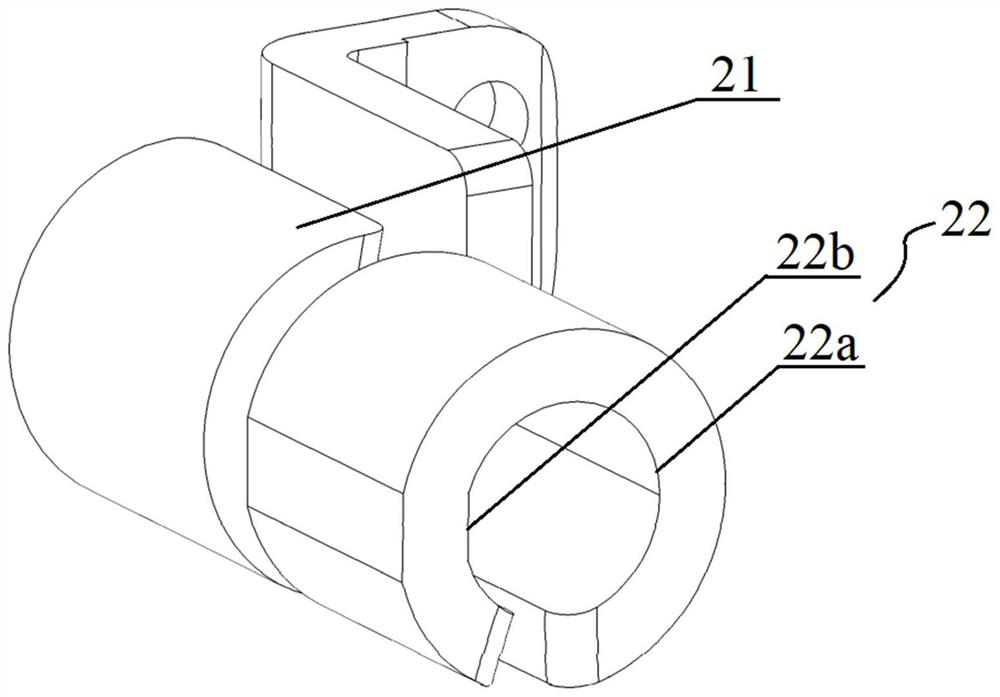

[0037] This embodiment provides a shaft mechanism, such as Figure 1-Figure 3 As shown, the rotating shaft mechanism includes: a rotating shaft bearing 1 and a torsion member 2 . Wherein, the rotating shaft bearing 1 includes a first bearing portion 11 and a second bearing portion 12, and the radius of the second bearing portion 12 is smaller than the radius of the first bearing portion 11; the rotating shaft bearing 1 is rotatably arranged in the torsion member 2, and the torsion member 2 includes a first torsion portion 21 surrounding the first bearing portion 11 and a second torsion portion 22 surrounding the second bearing portion 12, and the second torsion portion 22 includes a second avoidance portion 22a and a second braking portion 22b; the first The torsion portion 21 abuts against the first bearing portion 11 to generate a torsion force, and the second braking portion 22b abuts to the first braking portion 12b to generate a torsion force.

[0038] In this embodiment...

Embodiment 2

[0053] This embodiment provides an electronic device, which includes a first body, a second body, and the shaft mechanism described in Embodiment 1 above, the first body and the second body are connected to the shaft bearing 1 and the torsion member 2 respectively .

[0054] Such as figure 1 , Figure 5 and Figure 6 As shown, a body mounting part 4 is fixedly connected to the torsion part, and the second body is connected to the torsion part 2 through the body mounting part 4. Of course, the body mounting part 4 can also be directly integrally connected with the torsion part 2, but compared to this In the case of integral molding, by fixing a body mounting part 4 on the torsion member 2 and connecting the second body with the torsion part 2 through the body mounting part 4, the body mounting part 4 can exist independently from the torsion part 2, Thereby the thickness of above-mentioned machine body mounting part 4 can not be restricted by torsion part 2, or while guaranteei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com