High-precision screw drive fixed-point passive mapping follow-up tracking focusing system and method

A follow-up tracking and high-precision technology, applied in the field of tracking and positioning, can solve the problems of poor tracking effect and achieve the effect of accurate tracking and simple equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

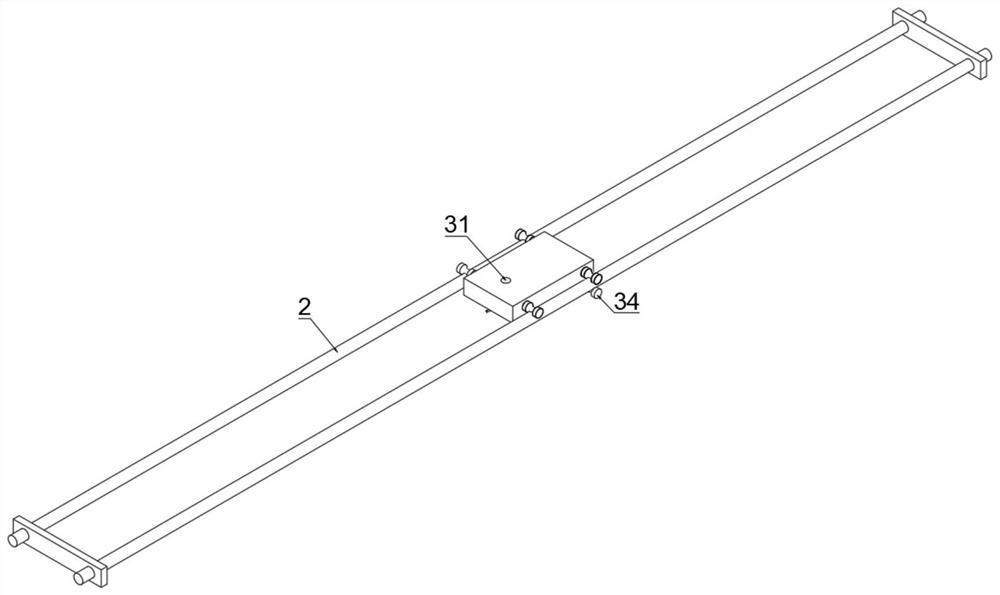

[0038] refer to figure 1 , a high-precision screw drive fixed-point passive mapping follow-up tracking focusing system, including: a traverse track 1, a structure used to move on it, track brackets are installed at both ends of the traverse track 1, and the track brackets are erected on On the ground, keep the traverse track 1 stable.

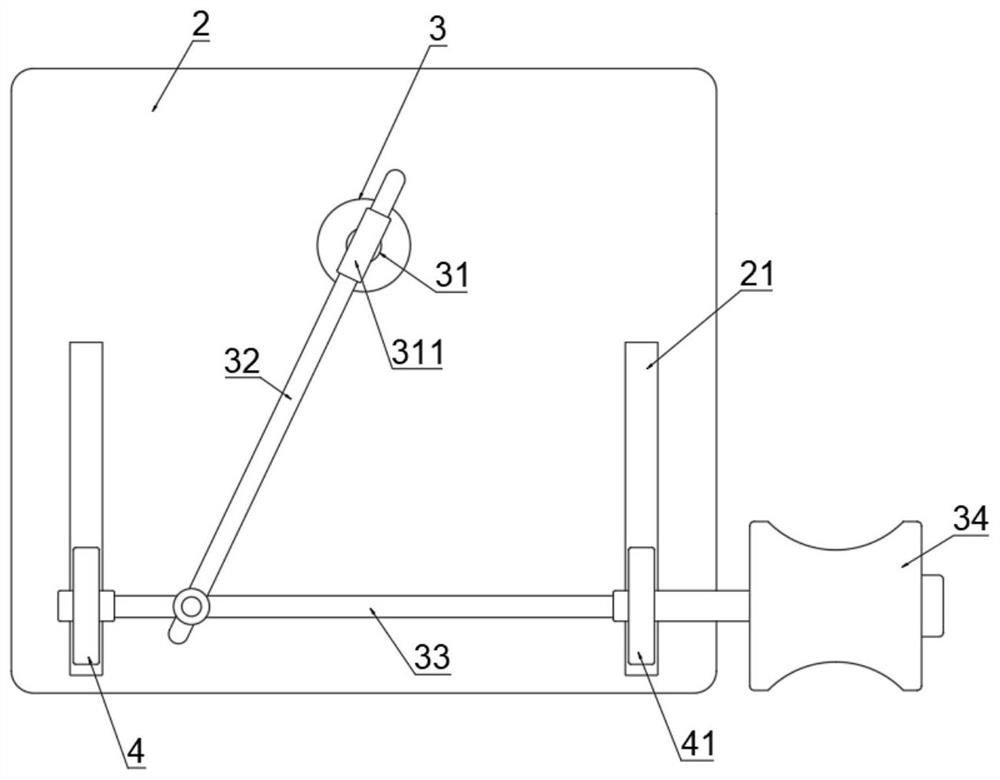

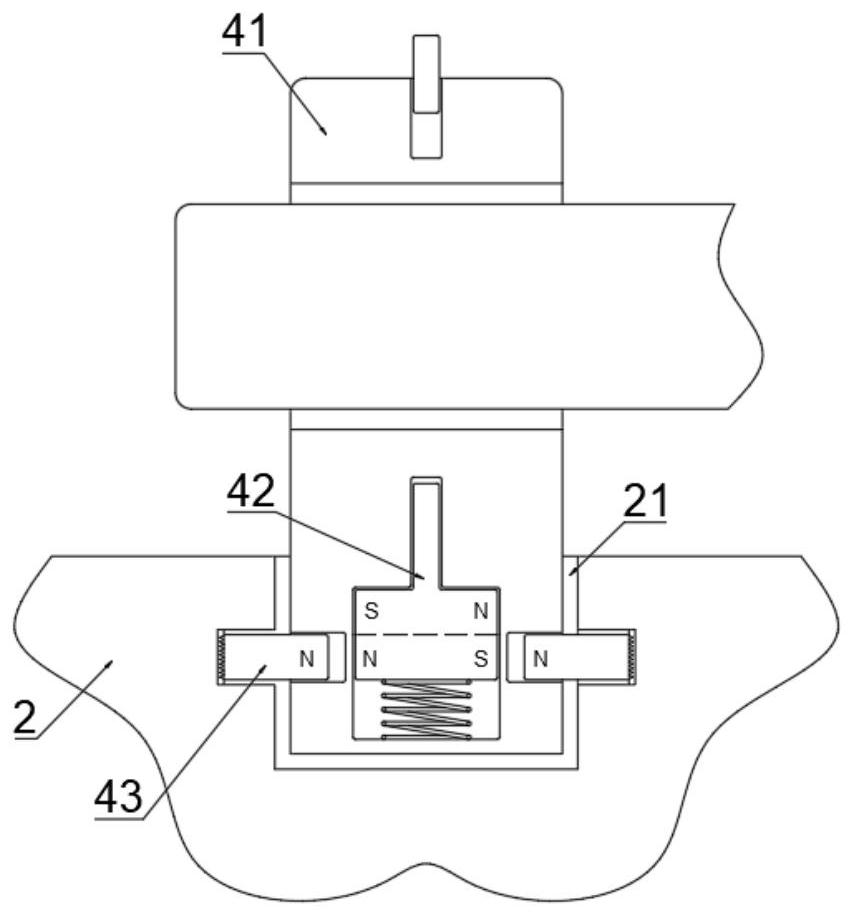

[0039] The pan-tilt 2 is used to carry the tracking and adjusting mechanism. The pan-tilt 2 is rollingly connected to the traversing track 1 through the drive wheel 34 , and the pan-tilt 2 carries the tracking and adjusting mechanism to move on the traversing track 1 .

[0040] refer to figure 2, orienting mechanism 3, is used to c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com