Customized ring size measuring instrument

A measuring instrument and size technology, applied in the field of custom ring size measuring instruments, can solve the problems of poor flexibility, blurred scale, waste of manpower, etc., and achieve the effect of easy installation, placement and portability, prolonging service life, and improving accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

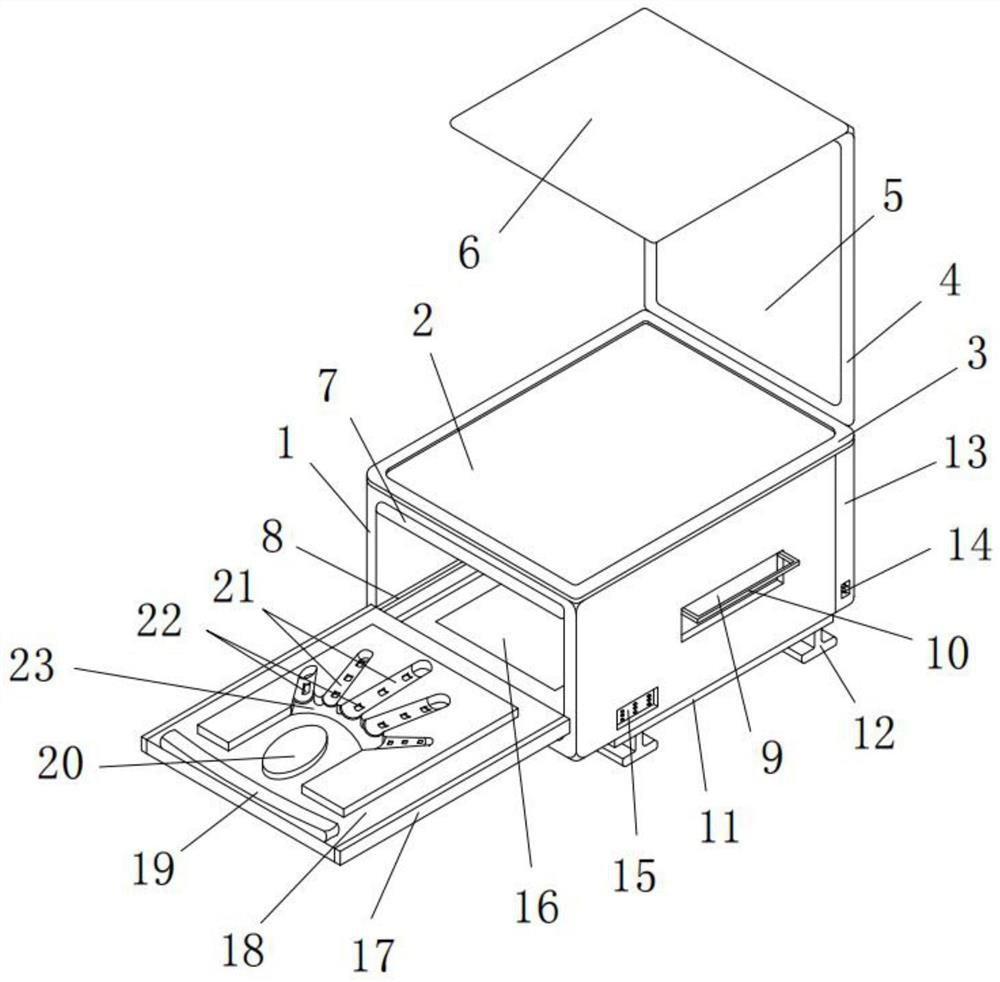

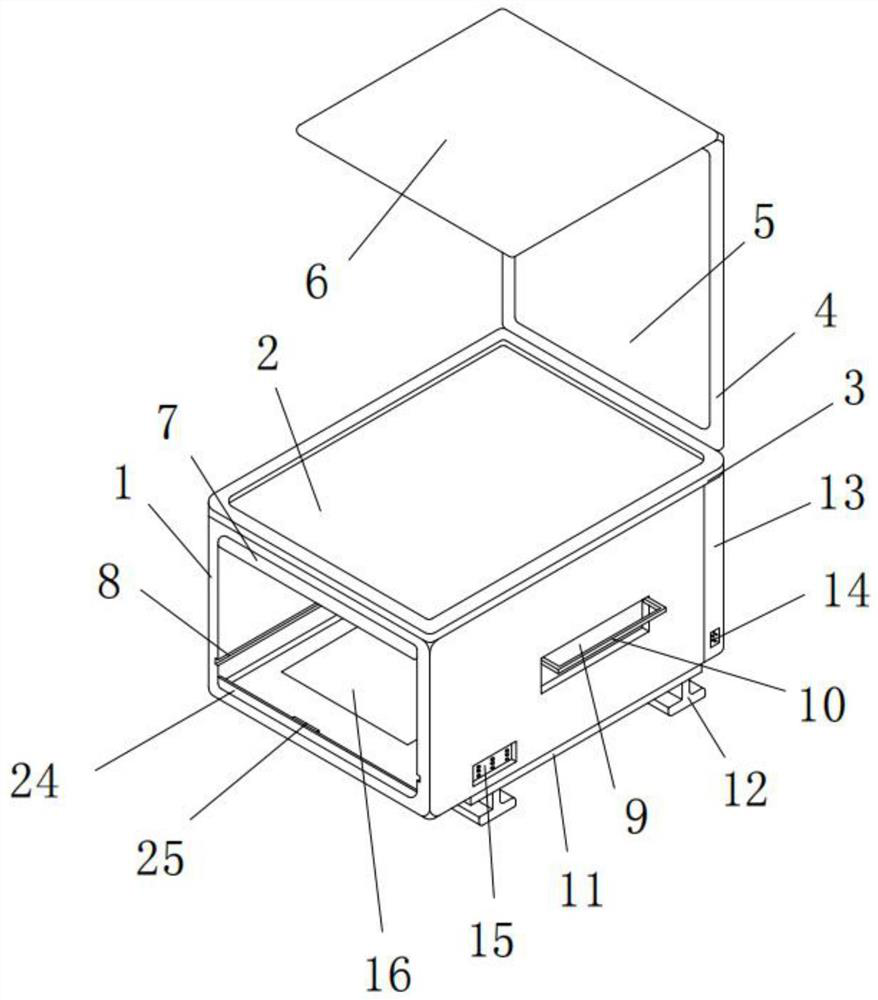

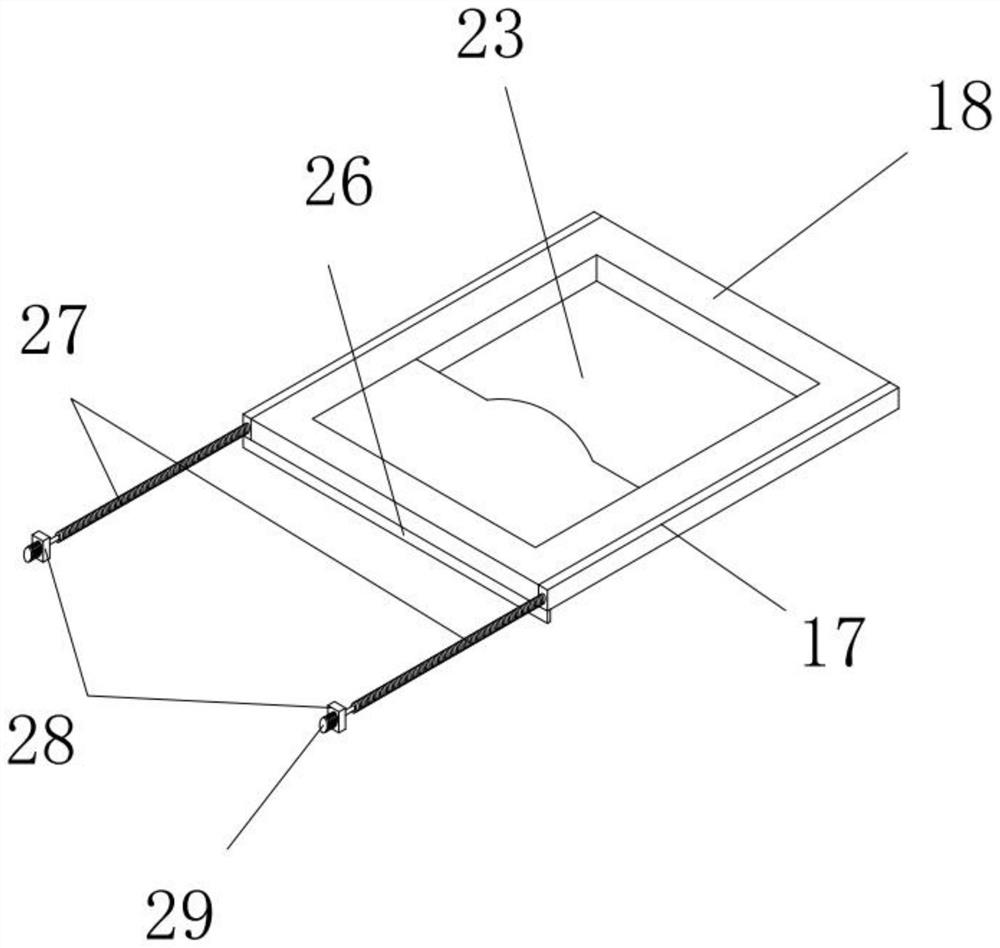

[0022] Example: see Figure 1-4 , the present invention provides a technical solution: a customized ring size measuring instrument, including a measuring instrument body 1, a display screen 2 is installed on the top of the measuring instrument body 1, a magnet plate 3 is installed on the outside of the top of the display screen 2, and the measuring instrument body One end of the top of 1 is connected with a top cover 4, a glass plate 5 is installed in the middle of the top cover 4, a side cover 6 is welded on one side of the top cover 4, and a first sensor fixing plate 7 is installed on the inner top of the measuring instrument body 1 to measure The inner bottom of the instrument body 1 is equipped with a second sensor fixing plate 16, and both sides of the interior of the measuring instrument body 1 are provided with a chute 8, one end of the chute 8 is equipped with a gear box 28, and one side of the gear box 28 is equipped with a Micromotor 29, the other side of gear case 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com