Cold rolling process steel bending detection and analysis method based on artificial intelligence

A technology of artificial intelligence and analysis methods, applied in image analysis, image data processing, instruments, etc., to save human resources, ensure quality, and reduce bending defects of steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

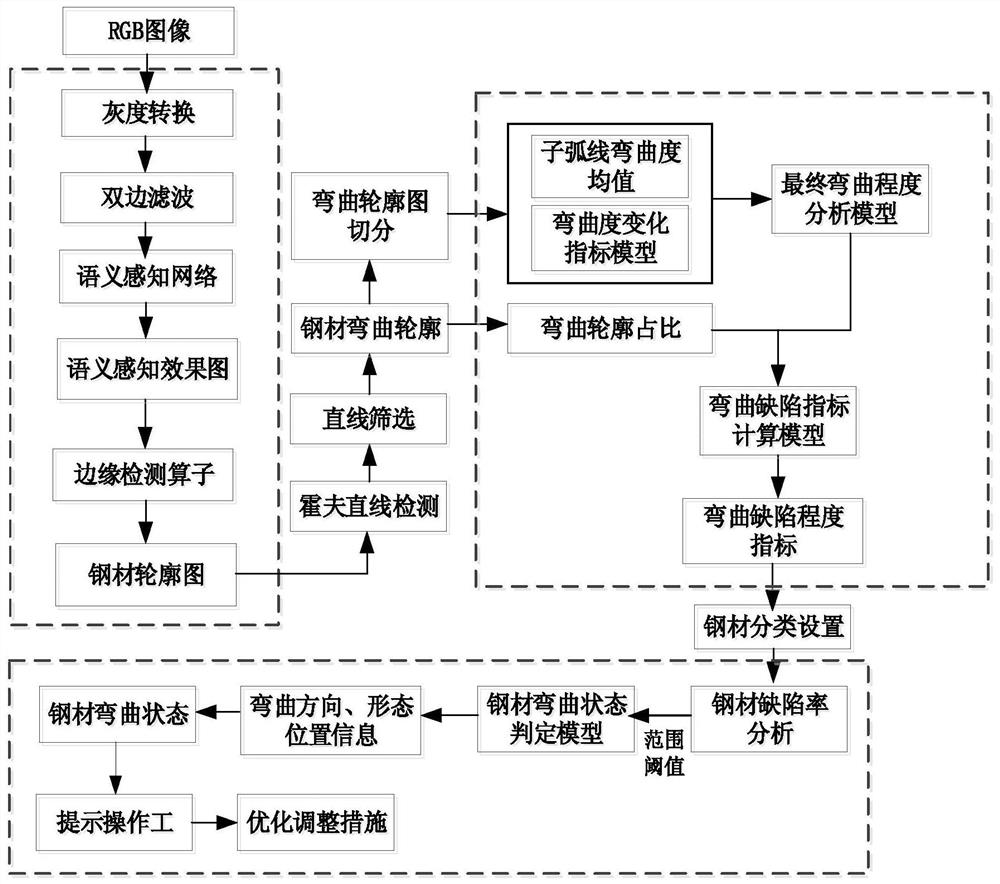

[0037]The artificial intelligence-based cold rolling process steel bending detection and analysis method of the present invention will be further described below in conjunction with the accompanying drawings and specific implementation methods: Bending defect detection, and analysis of bending defect status, to obtain specific bending defect information.

[0038] Step 1: Set up an RGB camera at the end of the cooling bed to take a complete image of the steel.

[0039] Step 2: Convert the collected image into a grayscale image, and then filter out the interference noise of the image through bilateral filtering, and save the edge information of the image at the same time.

[0040] Firstly, the grayscale processing is carried out on the collected data. The grayscale processing methods here include weighted average method, maximum value method, etc., which simplifies the three-channel information into single-channel information and reduces the amount of calculation.

[0041] Then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com