Lever labor-saving squeezing device and juicer

The technology of a squeezing device and a juicer is applied in the field of lever labor-saving devices, which can solve the problems of troublesome and troublesome cleaning, and achieve the effects of labor-saving operation, solving manual labor-saving and insufficient squeezing force, universal application value and market prospect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

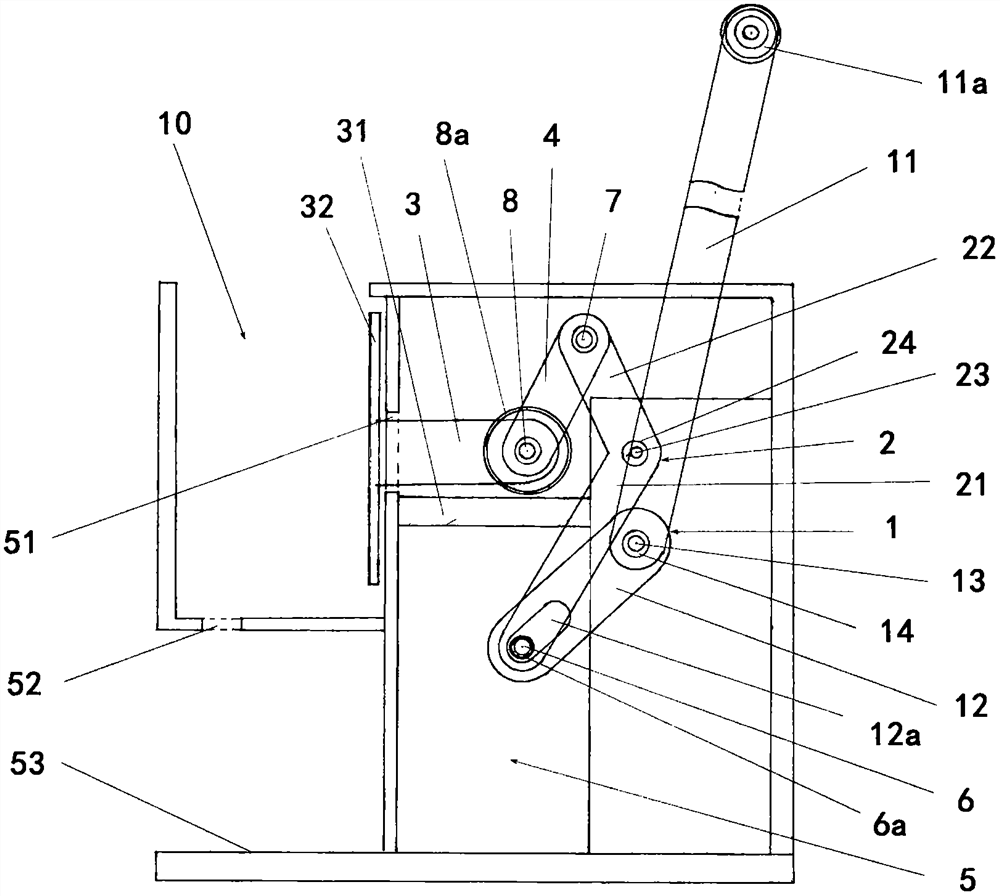

[0091] combine Figure 6 , refer to figure 1 , image 3 , Figure 4 , Figure 5 , Figure 7 as shown,

[0092] A lever labor-saving extrusion device, comprising a frame box 5, the top or side of the extrusion operation area 10 in the frame box 5 has an opening; it also includes a first lever 1, a second lever 2, an extrusion rod 3. Connecting rod 4, track 31;

[0093] The first lever 1 is composed of a hand lever 11 intersected with a short arm 12, the first end of the short arm 12 is the first lever fulcrum 13; the free end of the hand lever 11 is provided with a handle 11a ;

[0094] The first lever fulcrum 13 and the second lever fulcrum 23 are respectively movably connected to the rack box 5 through the first pin shaft 14 and the second pin shaft 24, and the first lever fulcrum 13 is located at the second Two lever fulcrums 23 are to the side of the long arm end 21, and its position is within the range of the rod length of the long arm end 21;

[0095] The second ...

Embodiment 2

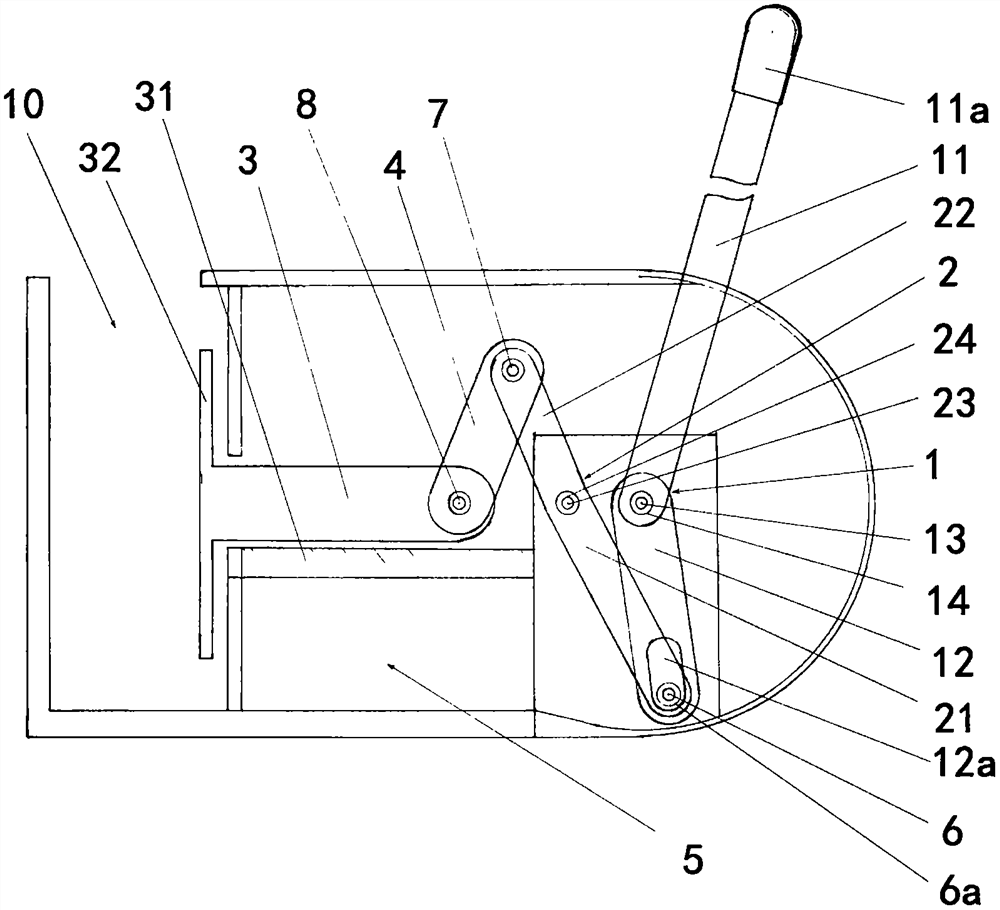

[0125] to combine Figure 8 , refer to figure 2 as shown,

[0126] A lever labor-saving extrusion device, comprising a frame box 5, the top or side of the extrusion operation area 10 in the frame box 5 has an opening; it also includes a first lever 1, a second lever 2, an extrusion rod 3. Connecting rod 4, track 31;

[0127] The first lever 1 is composed of a hand lever 11 intersected with a short arm 12, the first end of the short arm 12 is the first lever fulcrum 13; the free end of the hand lever 11 is provided with a handle 11a ;

[0128] The first lever fulcrum 13 and the second lever fulcrum 23 are respectively movably connected to the rack box 5 through the first pin shaft 14 and the second pin shaft 24, and the first lever fulcrum 13 is located at the second Two lever fulcrums 23 are to the side of the long arm end 21, and its position is within the range of the rod length of the long arm end 21;

[0129] The second end of the short arm 12 of the first lever 1 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com