Foaming cotton mop cleaning tool

A technology of cleaning tools and foamed cotton, applied in cleaning equipment, cleaning machinery, carpet cleaning, etc., can solve the problems of inconvenient operation, long water squeezing stroke, increased cost, etc., and achieve short time spent and short squeezing stroke , The effect of convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

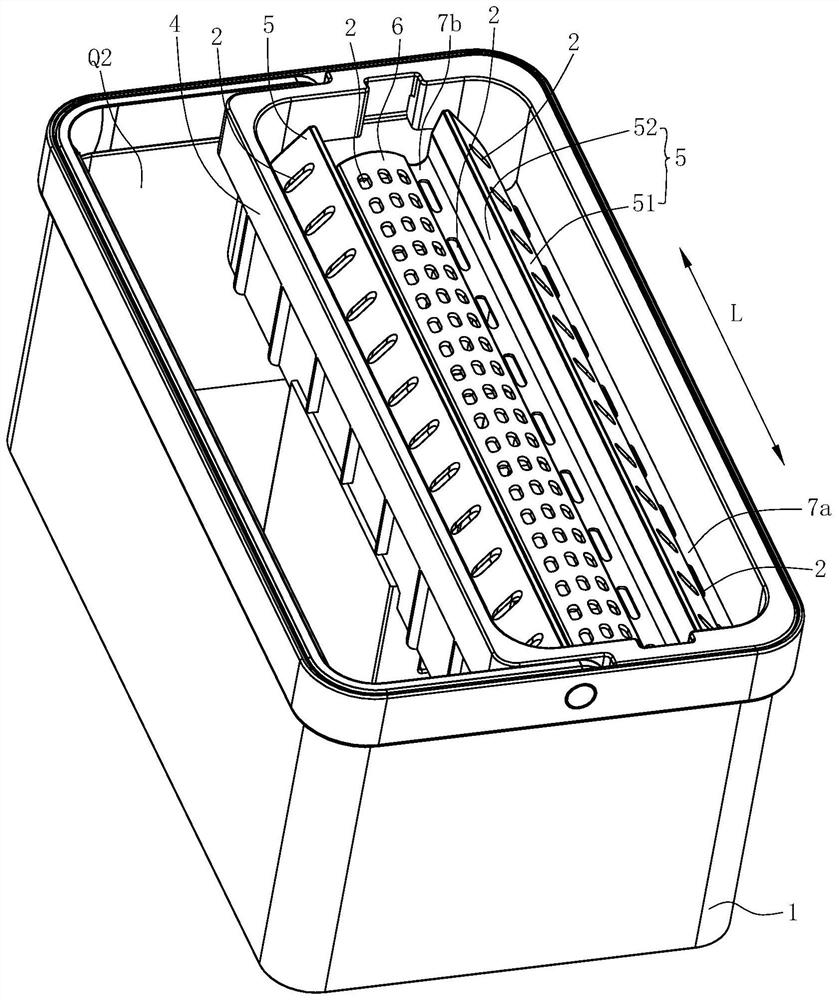

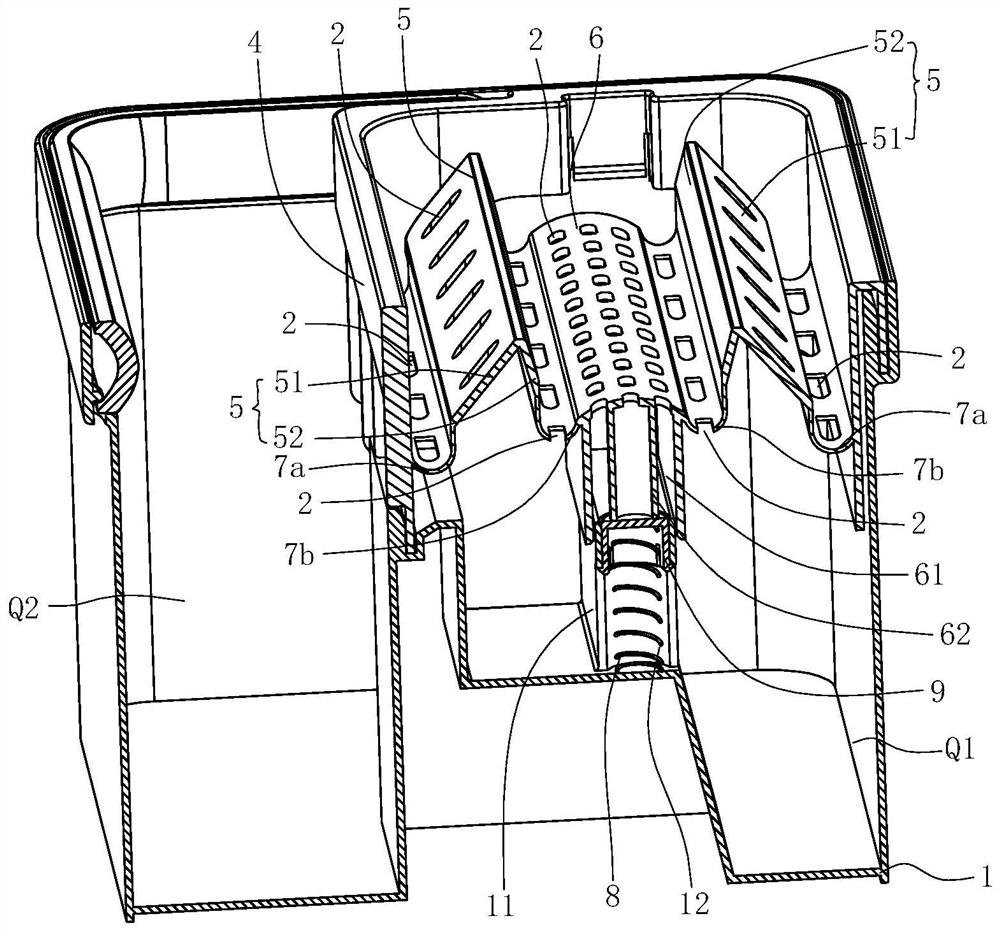

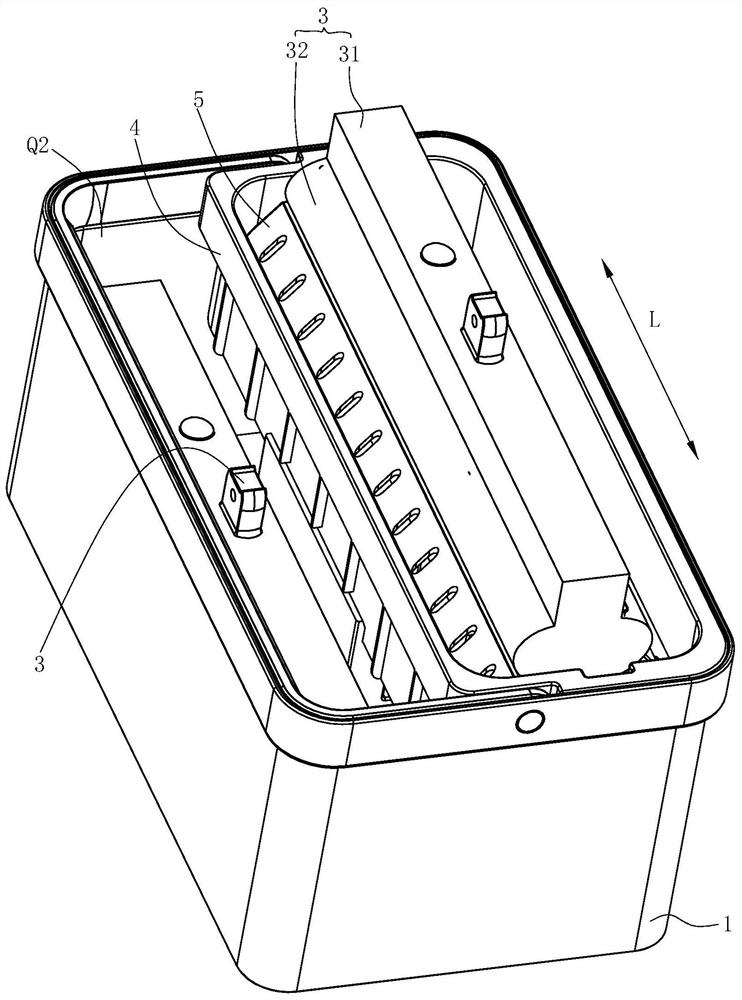

[0021] Such as Figure 1-8 Shown is a preferred embodiment of the present invention.

[0022] A foamed cotton mop cleaning tool, including a cleaning bucket 1 and a mop, the mop includes a mop head 3 connected to the lower end of the mop rod, the mop rod is not shown in the drawings, and the mop head 3 includes a mounting part 31 and a mounting part 31 The foamed cotton 32 at the bottom, the cleaning bucket 1 is installed with an extruded frame 4, and the extruded frame 4 is provided with a water-squeezing structure for squeezing the foamed cotton 32, and the foamed cotton has a certain thickness and strong water absorption. The cleaning barrel 1 is divided into a squeezing area Q1 and a cleaning area Q2. The squeezing frame is arranged in the squeezing area Q1. The cleaning area is for the mop head 3 to enter, and the mop head 3 can be clean...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com