Multifunctional medicine grinding device

A grinding device and multi-functional technology, which can be used in grain processing, feeding and oral medicine, etc., can solve the problems of drug residues, inability to select grinding powder particles in a targeted manner, and difficult to clean.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

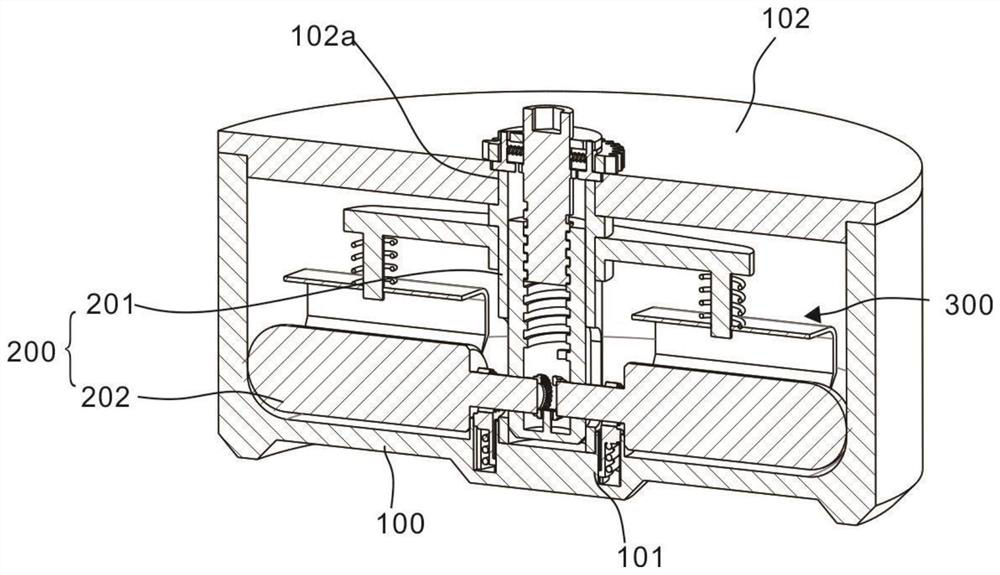

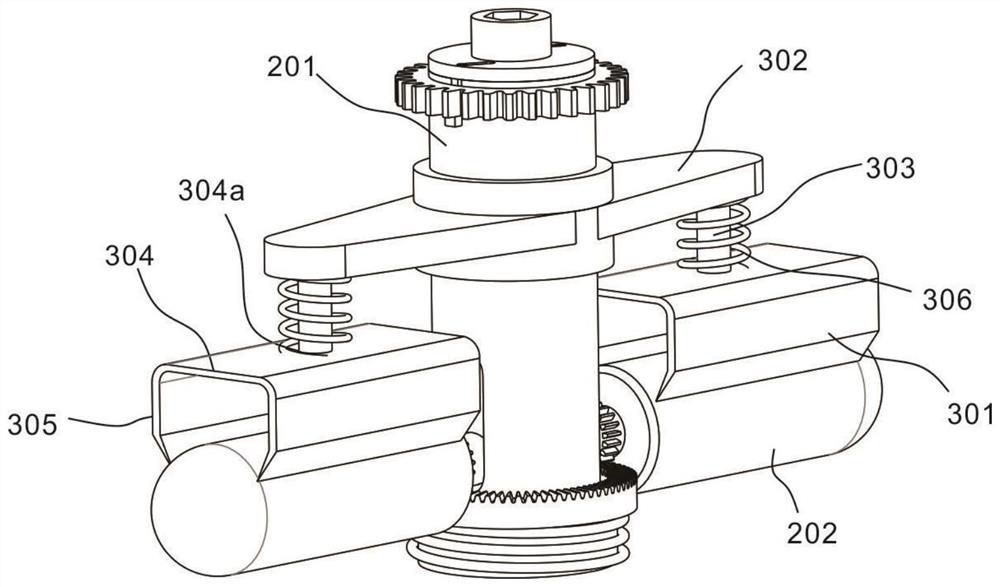

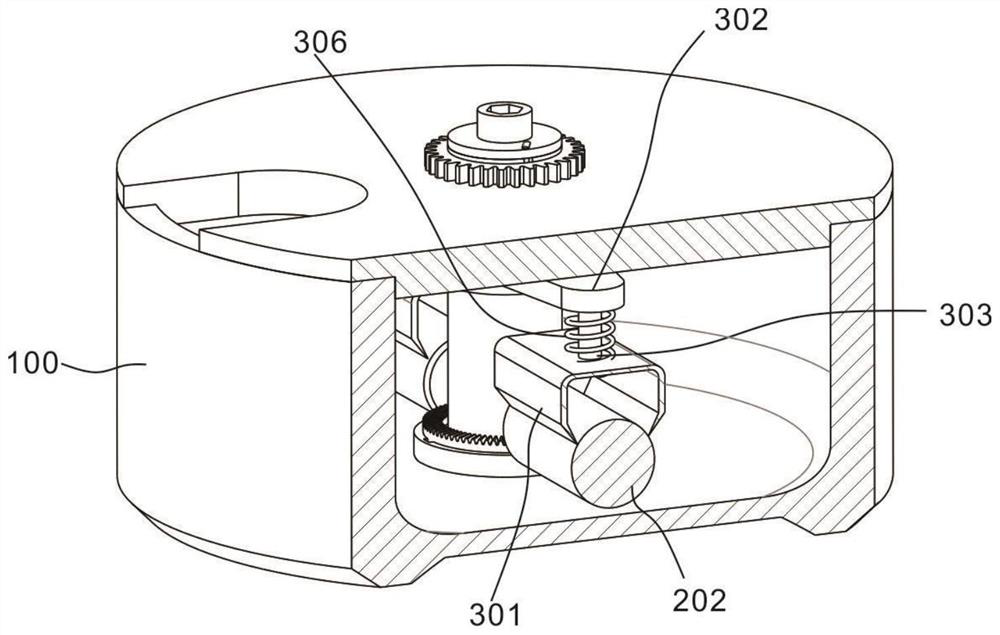

[0032] Refer Figure 1 ~ 3 This embodiment provides a multifunctional drug abrasive device, including accommodating tank 100, abrasive assembly 200, and blade assembly 300, accommodating tank 100 for accommodating the drug, the blade assembly 300 is used to scrape the residue of the abrasive assembly 200. Drug; specifically, the abrasive assembly 200 includes a rotating shaft 201 disposed within the accommodating tank 100, a grinding rod 202 is connected to the rotating shaft 201 and is located radially in the rotation shaft 201; the blade assembly 300, including provided in the accommodating can 100 And the scraper member 301 on the surface of the abrasive rod 202 is contracted. However, the blade assembly 300 includes a link 302 connected to the rotating shaft 201, and the link 302 is provided with a guide rod 303 in the axial direction of the rotating shaft 201; the link 302 is fixed to the rotating shaft 201, and the blade 301 includes and the guide. The slide 304 connected to ...

Embodiment 2

[0037] Refer Figure 1 ~ 8 For the second embodiment of the present invention, this embodiment is based on the previous embodiment, and is different from the above-in-one embodiment: the accommodating tank 100 is used to accommodate the drug, and the abrasive assembly 200 is ground to the drug.

[0038] Specifically, the accommodating tank 100 includes a ring boss 101 disposed at the bottom of the tank 100, a cover 102 provided at the accommodating tank 100, and the cover 102 is provided with a rotating hole 102a; the annular boss 101 is disposed The center position of the can 100; the abrasive assembly 200 includes a grinding shaft 201 that passes through the rotating hole 102a and at one end to the annular boss 101, and is connected to the rotating shaft 201 and located radially radial in the rotation shaft 201. Therefore, the annular boss 101 is common to the rotating hole 102a to limit the axial and radial offsets of the rotation shaft 201, and the gap between the abrasive rod 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com