Reverse pressing plate type horizontal milling double-cutter milling double-face clamping device

A clamping device and clamping plate technology, which is applied in the field of mechanical processing tooling, can solve problems such as not being able to meet the requirements of one-time fast clamping of double-facade workpieces, and achieve the effects of improving processing efficiency and precision, easy operation, and scientific and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

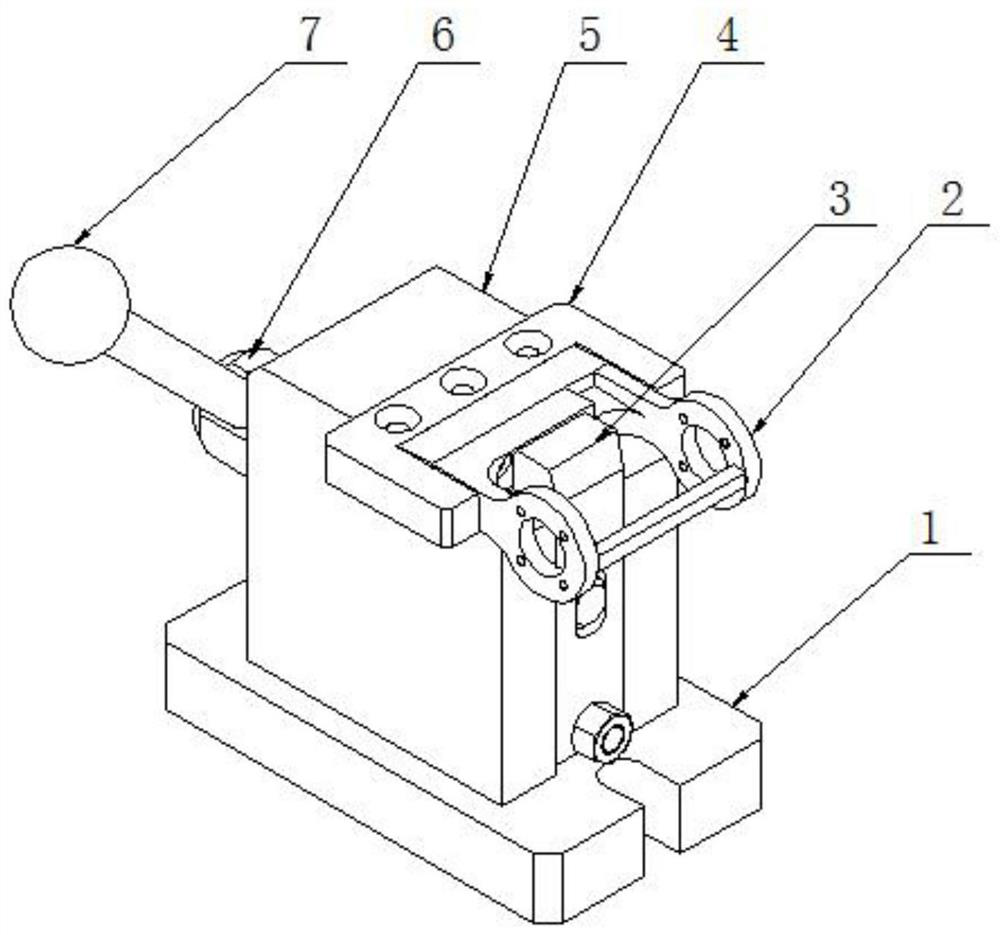

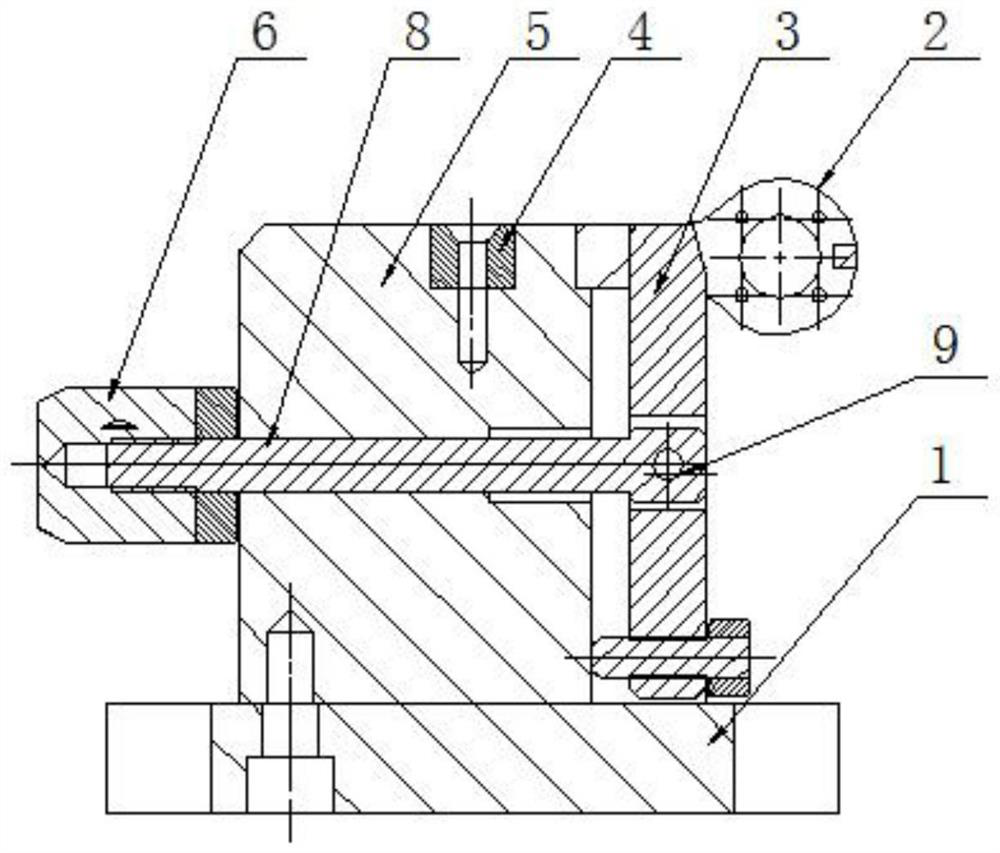

[0016] A double-sided clamping device for horizontal milling, double-cutter milling and double-sided clamping of a reverse pressure plate, which includes a base 1, a vertical base 5, a pressure plate 3, a pull rod 8, a pull rod cover 6, a handle 7 and a U-shaped clamping plate 4, fixedly installed on the upper surface of the base Vertical seat, wear the pull rod horizontally on the vertical seat, install the pull rod cover on the rear end of the pull rod, install the handle on the pull rod cover, thread the connection between the pull rod cover and the pull rod, the front end of the pull rod extends out of the stand and fixes it with the pressure plate, A U-shaped clamping plate is fixedly installed on the upper end of the seat, and a workpie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com