A cap screwing mechanism and its control method

A control method and capping technology, which is applied in packaging and other fields, can solve problems such as the inapplicability of automatic capping equipment and capping of soft bag packaging containers, and achieve the effects of compact structure, stable operation, and simplified control process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

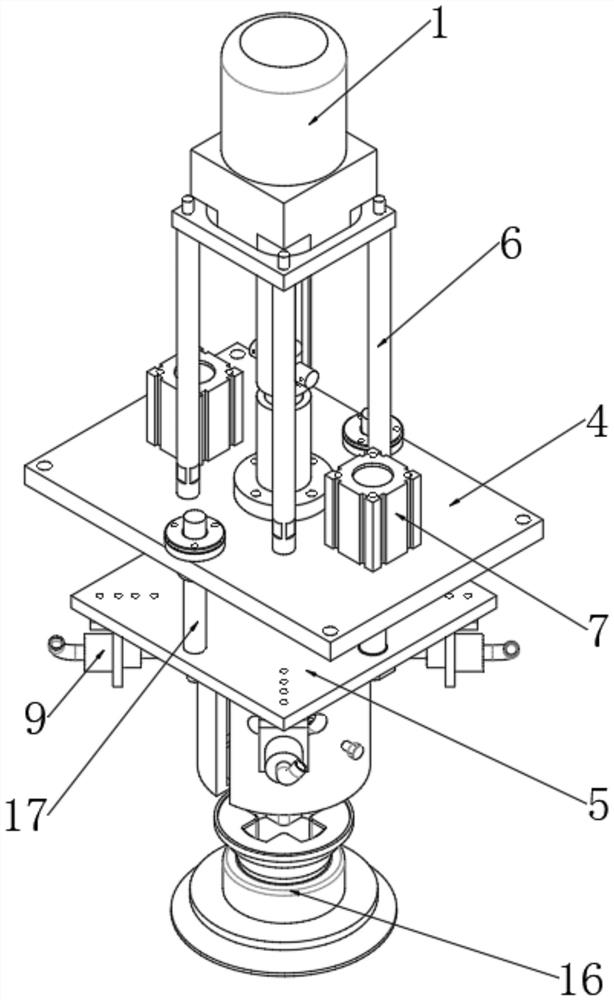

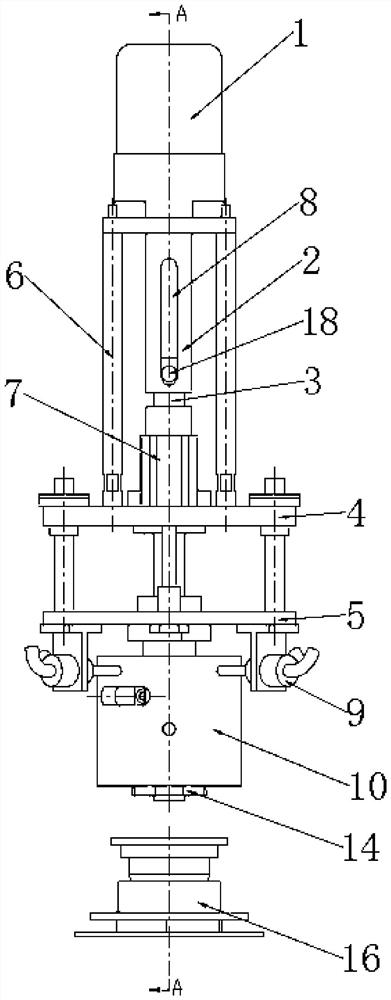

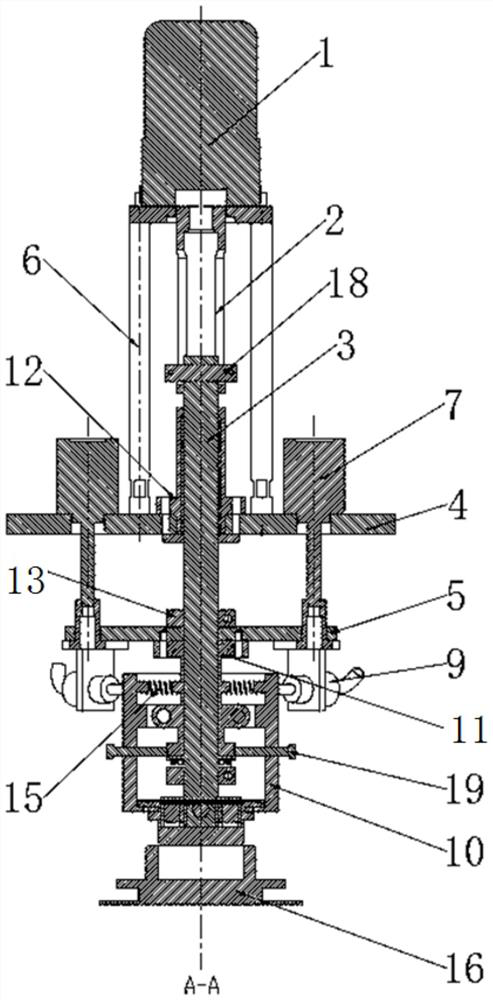

[0034] The technical solutions of the present invention will be clearly and completely described below with reference to the embodiments of the present invention and the accompanying drawings. Obviously, the described embodiments do not limit the present invention.

[0035] A capping mechanism includes a holding clip 10 , a guide rod 17 , a first platform 4 , a second platform 5 , a rotating motor 1 , a connecting rod 2 and a rotating lifting rod 3 connected in sequence. The rotating electrical machine 1 is fixed to the first platform 4 through a support rod 6 .

[0036] The connecting rod 2 is connected with the output end of the rotating motor 1, and the rotating motor 1 drives the connecting rod 2 to rotate; the connecting rod 2 is provided with a sliding groove along the axial direction, and one end of the rotating lifting rod 3 is matched and connected with the sliding groove 8, The rotating lifting rod 3 can be driven to rotate synchronously by the connecting rod, and ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com