Novel light-transmitting superconductive automotive interior material and preparation method thereof

An automotive interior, superconducting technology, applied in the direction of coating, can solve the problems of single appearance, difficult to meet environmental protection requirements, lack of technology and modernity, etc., to achieve improved vision and touch, continuous production, flame retardant performance Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

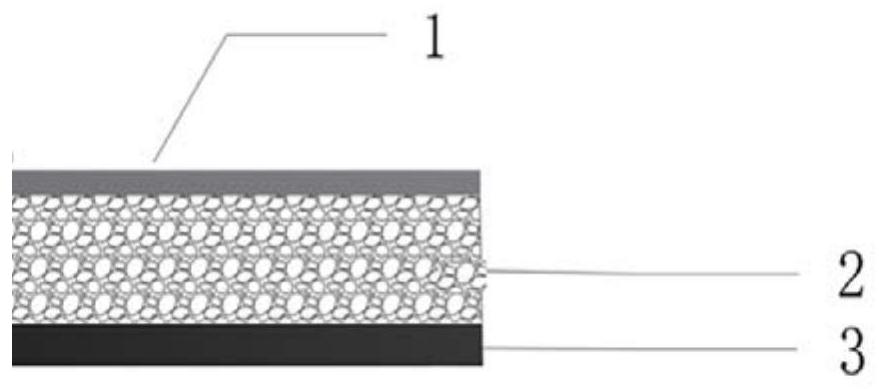

[0034] The translucent superconducting automotive interior material provided by this embodiment, such as figure 1 As shown, the automotive interior material includes a surface treatment layer 1, a TPO film layer 2 and a back treatment layer 3 arranged in sequence.

[0035] The material used for the surface treatment layer 1 is water-based two-component polyurethane resin with a solid content of 25%.

[0036] The material used for the back treatment layer 3 is water-based polyolefin resin with a solid content of 28%.

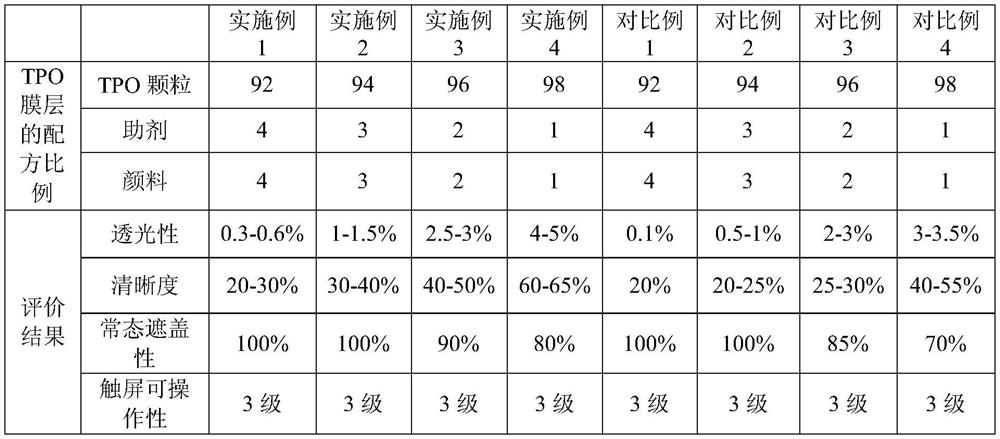

[0037] The raw material formula that TPO film layer 2 adopts is as shown in table 1, wherein,

[0038] Modified TPO particles are thermoplastic elastomers, model RG-30, purchased from Mitsui Corporation.

[0039] The additive is hindered amine light stabilizer.

[0040] The pigment is a pigment containing metal particles with a particle size of 0.3-1 μm, specifically, the pigment purchased from Ximeishi, model 2686.

[0041] The automotive interior material i...

Embodiment 2

[0047] The light-transmitting superconducting automotive interior material provided in this embodiment, the raw material formula of the TPO film layer in the automotive interior material is shown in Table 1, and the others are the same as in Example 1.

Embodiment 3

[0049] The light-transmitting superconducting automotive interior material provided in this embodiment, the raw material formula of the TPO film layer in the automotive interior material is shown in Table 1, and the others are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com