Slow motion belt solid-liquid separation method

A solid-liquid separation and belt technology, which is applied in loading/unloading, conveyors, grain processing, etc., can solve the problems of difficult processing, affecting normal production, and occupying a large space, so as to expand the application field and solve the problem of incomplete separation, Overcome the effect of narrow space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

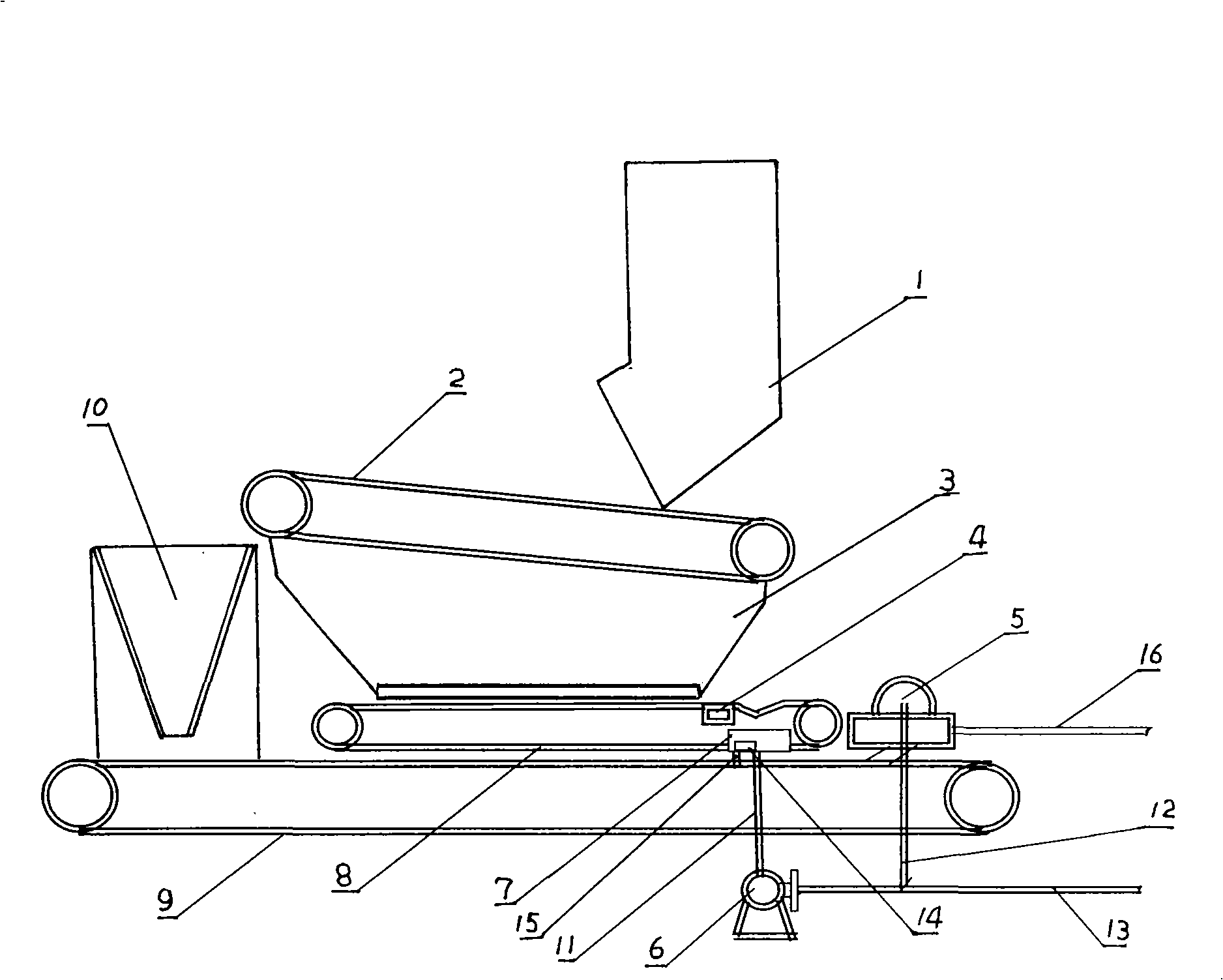

[0012] The applicable equipment is the 12000×2400 heavy plate machine feeding jaw crusher system. At the bottom of the powder ore box 3 of the heavy plate machine in the flat hole, a separation belt 8 of 17m * 1.2m is installed above the conveyor belt 9 of the belt conveyor. The size of the conveyor belt 9 of the belt conveyor is 1200m * 1.2m, and the belt speed is 1.25m / s. The speed of the separation belt 8 is lower than 0.25m / s, which is determined through experiments depending on the amount of falling material, the separation effect and the settling velocity of solid matter.

[0013] When the ore in the mining field enters the ore crushing system from the vertical shaft 1, the surface water and groundwater also enter. The ore in the shaft is transported into the crushing cavity 10 of the jaw crusher through the heavy plate conveyor 2 . The ore overflowing or leaking from the gap of the chain plate of the heavy plate conveyor 2 together with the muddy water falling in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com