Steel slag modifier as well as preparation and use methods thereof

A modifier and steel slag technology, applied in the field of iron and steel metallurgy, can solve the problems of poor melting effect and low oxidizing ability of steel slag, and achieve the effects of improving ductility, increasing effective utilization rate, and improving slag state.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

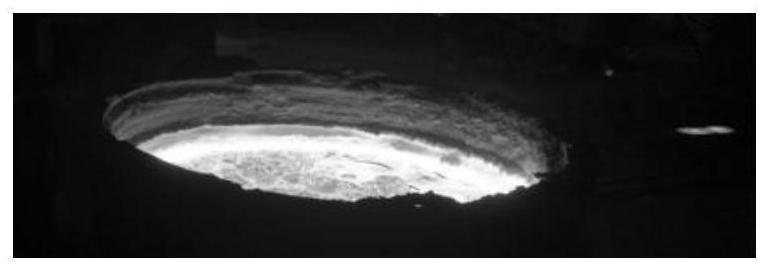

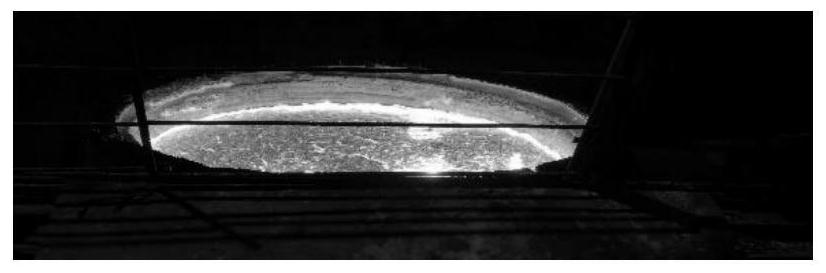

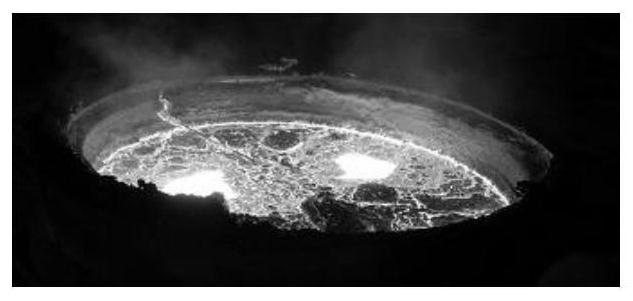

Image

Examples

preparation example Construction

[0031] The present invention also provides a method for preparing the above-mentioned steel slag modifier, comprising the following steps:

[0032] a. Dry mix, mix and stir the main dry material for 8-10 minutes, then add the auxiliary material forming binder and mix for 5-7 minutes to prepare the dry mix;

[0033] b. Prepare steel slag modifier pellets with a size of 10-20mm by dry-type briquetting with a powerful briquetting machine;

[0034] c. Screening, sieving the steel slag modifier pellets with a sieve hole of 5 mm, and selecting steel slag modifier pellets with a particle size larger than 5 mm as steel slag modifier pellets.

[0035] The present invention also provides a method for using the steel slag modifier, comprising the following steps:

[0036] The amount of lime added in converter tapping ladle slag washing is controlled by 800kg-1000kg / furnace, and steel slag modifier is added 1-3 minutes after tapping, and the addition amount is 450-550kg / furnace; Then st...

Embodiment 1

[0041] The semi-steel after vanadium extraction and desulfurization of vanadium-containing titanium hot metal is used as raw material for primary molten steel, wherein the semi-steel contains 3.48% of C, 0.039% of Mn, 0.065% of P, 0.005% of S, 0.015% V and traces of Cr, Si and Ti, the balance being iron and unavoidable impurities.

[0042] Specific steps:

[0043] (1) Put 23 tons of the above-mentioned semi-steel into a 220-ton (nominal capacity) top-bottom combined blowing converter, and use the function of the top-bottom combined blowing converter to blow oxygen and decarburize the above-mentioned semi-steel into molten steel. When the molten steel is initially smelted to a C content of 0.038wt%, a Mn content of 0.027wt%, a P content of 0.0072wt%, a S content of 0.0061wt%, and a temperature of 1660°C, the thick slag begins to be tapped into the ladle.

[0044] (2) Lime was added after 1 minute of tapping, and the addition of lime was completed 2 minutes after tapping starte...

Embodiment 2

[0050] The semi-steel after vanadium extraction and desulfurization of vanadium-containing titanium hot metal is used as raw material for primary molten steel, wherein the semi-steel contains 3.72% of C, 0.036% of Mn, 0.068% of P, 0.005% of S, 0.017% V and traces of Cr, Si and Ti, the balance being iron and unavoidable impurities.

[0051] Specific steps:

[0052] (1) Add 243 tons of the above-mentioned semi-steel into a 220-ton (nominal capacity) top-bottom combined blowing converter, and use the function of the top-bottom combined blowing converter to blow oxygen and decarburize the above-mentioned semi-steel into molten steel. When the molten steel is initially smelted to a C content of 0.037wt%, a Mn content of 0.020wt%, a P content of 0.0082wt%, a S content of 0.0061wt%, and a temperature of 1675°C, the thick slag begins to be tapped into the ladle.

[0053] (2) Lime is added 1 minute after tapping, and the lime addition is completed 1 minute after tapping begins. A tota...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com