Double-arm yarn guide hook

A yarn guide and double-arm technology is applied in the field of yarn guides, which can solve the problems of difficult surface treatment, redundant action, time-consuming and laborious, and inconvenient processing, so as to reduce the workload of check-in vehicles, improve the stand capacity, and simplify the operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

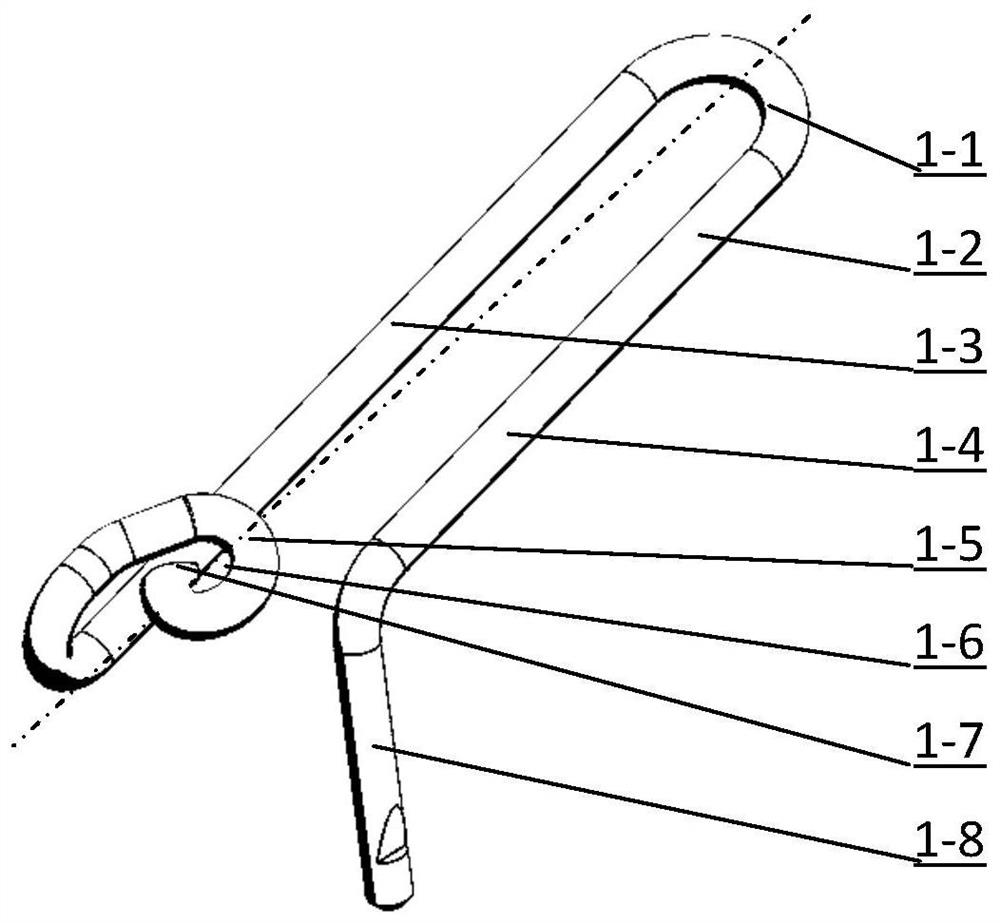

[0021] Example 1 see figure 1 , the two arms of the U-shaped tail part 1-1 and the fixed part 1-2 are the yarn guide arm 1-3 and the yarn capture arm 1-4, which respectively extend the yarn guide 1-5 and the yarn capture device 1-8, and the guide The yarn arm 1-3 is bent from bottom to top, and then the center line of the guide yarn hook is bent to form a spiral annular yarn guide 1-5 with a yarn guide hole 1-6 in the center, and the end of the yarn guide 1-7 is bent downward Fold, yarn catcher 1-8 catches yarn end downward.

Embodiment 2

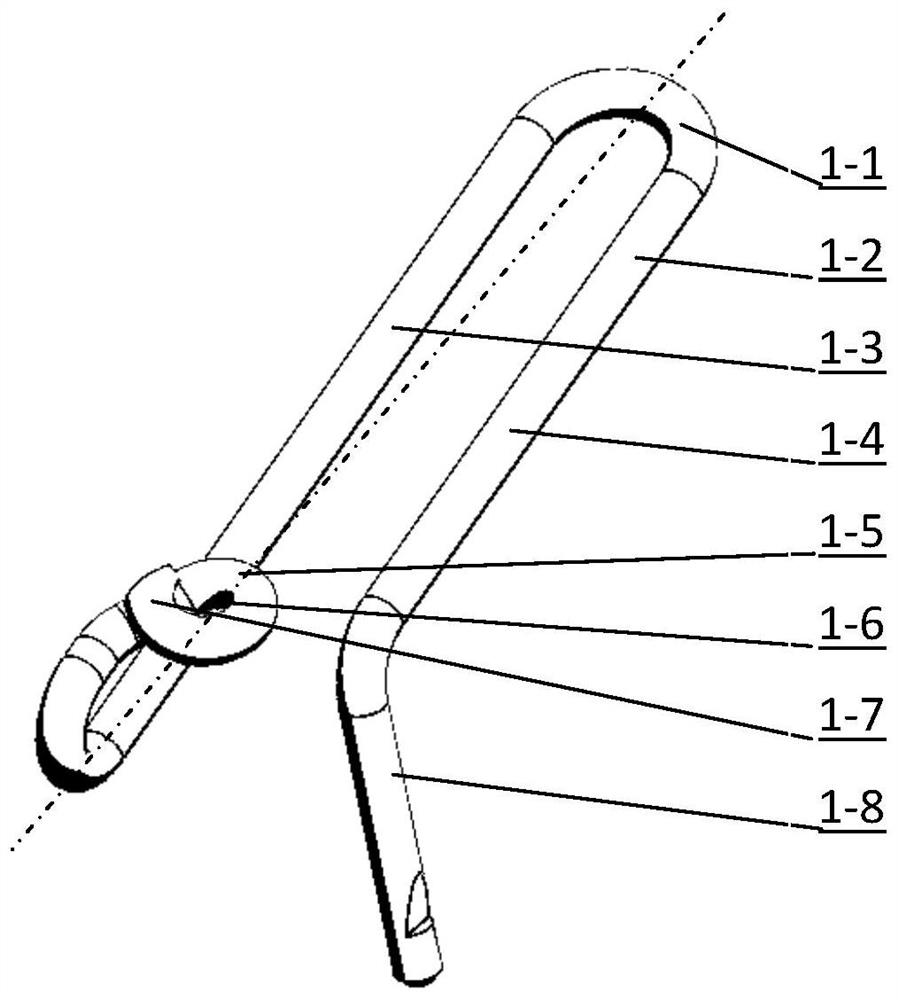

[0022] Example 2 see figure 2 , the two arms of the U-shaped tail part 2-1 and the fixed part 2-2 are the yarn guide arm 2-3 and the yarn capture arm 2-4, which respectively extend the yarn guide 2-5 and the yarn capture device 2-8, and the guide The yarn arm 2-3 is bent from bottom to top, and then the center line of the guide yarn hook is bent to form a spiral annular yarn guide 2-5 with a yarn guide hole 2-6 in the center, and the end of the yarn guide 2-7 is bent upward , Yarn catcher 2-8 catches yarn end downward.

Embodiment 3

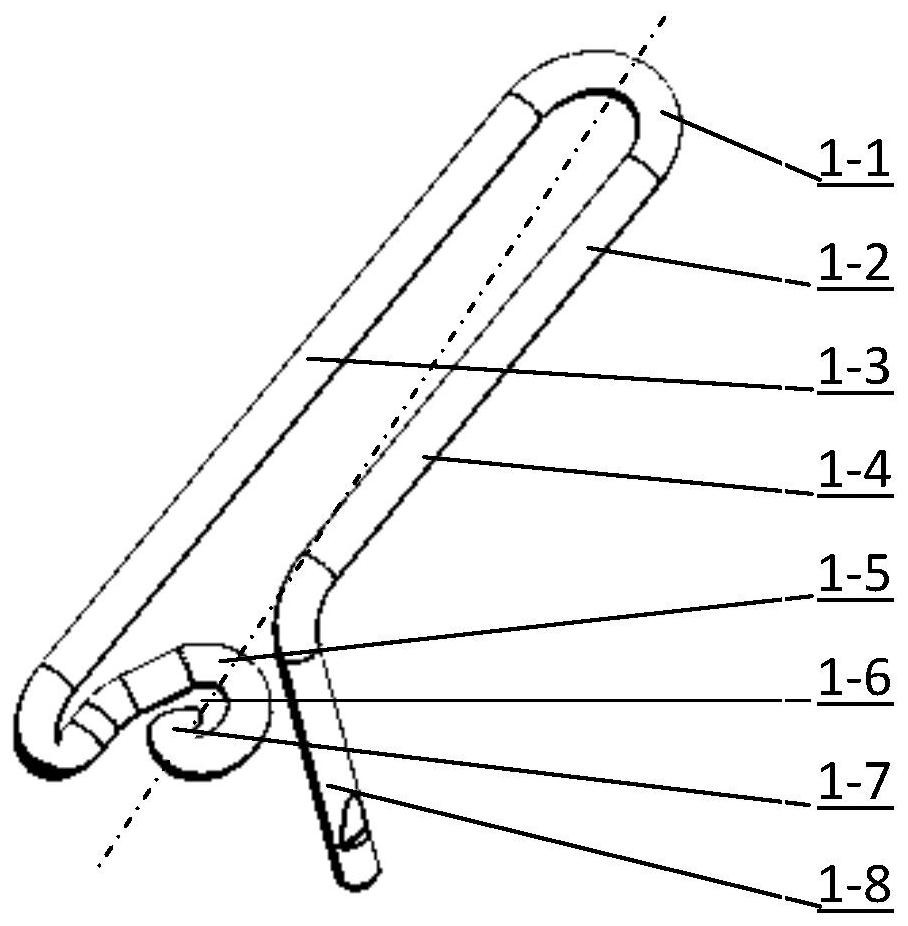

[0023] Example 3 see image 3 , the two arms of the U-shaped tail part 3-1 and the fixed part 3-2 are the yarn guide arm 3-3 and the yarn capture arm 3-4, which respectively extend the yarn guide 3-5 and the yarn capture device 3-8, and the guide The yarn arm 3-3 is bent from top to bottom, and then the center line of the guide yarn hook is bent to form a spiral annular yarn guide 3-5 with a yarn guide hole 3-6 in the center, and the end of the yarn guide 3-7 is bent downward Fold, yarn catcher 3-8 catches yarn end downward.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com