Horizontal frozen pipe drawing device

A freezing tube and horizontal technology, applied in mining equipment, mining equipment, tunnels, etc., can solve the problems of increasing the difficulty of extubation, high personal risk, scaffolding pulling to the direction of the ground and wall, and even bending, etc., to achieve easier The effect of pulling out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

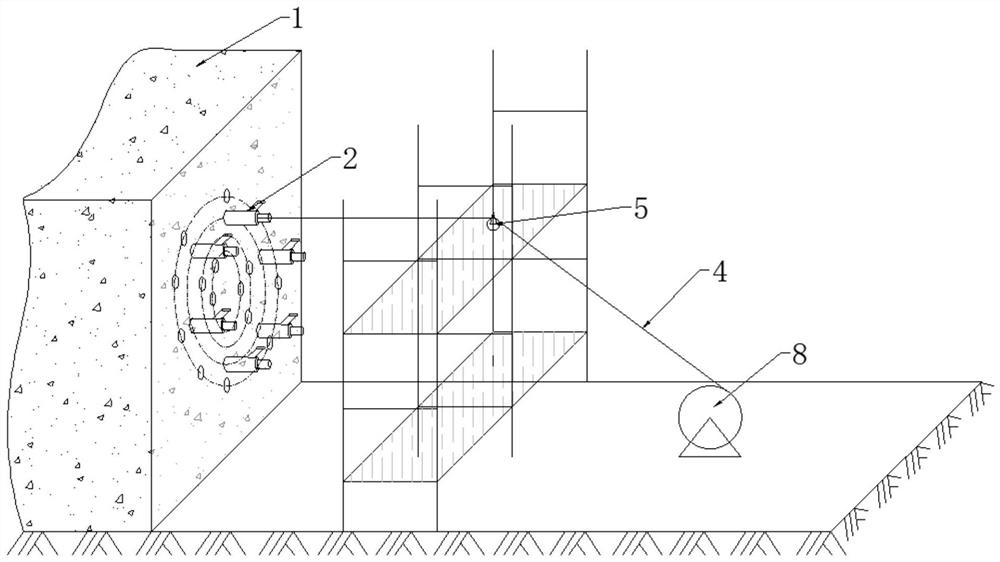

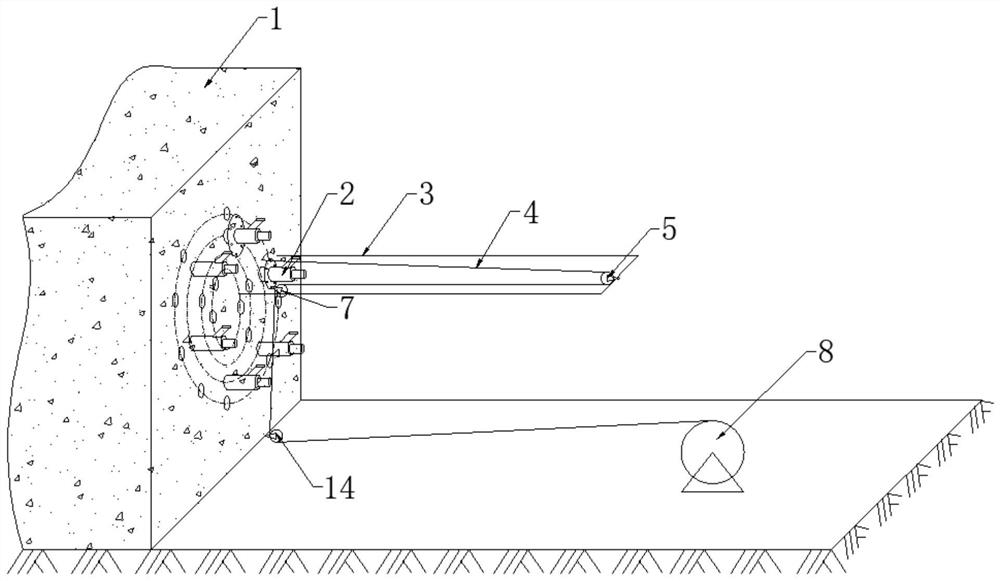

[0033] Such as figure 2 and Figure 5 As shown, the horizontal frozen tube extubation device of this embodiment includes a steel wire rope 4, a hoist 8, an extubator support 3, a first fixed pulley 5, a second fixed pulley 7, a third fixed pulley 14 and a fourth fixed pulley 15; The first end of the tube holder bracket 3 abuts against the facade of the ground connection wall structure 1, the first fixed pulley 5 is fixedly installed on the second end of the tube puller bracket 3; the second fixed pulley 7 is fixedly installed on the On the flange plate 2 of the horizontal freezing pipe freezer; the third fixed pulley 14 is fixedly installed on the facade of the ground connection wall structure 1 where the flange plate 2 of the horizontal freezing pipe freezer to be removed; the fourth fixed pulley 15 is fixedly installed on On the tube puller bracket 3; one end of the steel wire rope 4 is a steel hook structure, and is fixedly connected with the flange plate 2 of the freezer...

Embodiment 2

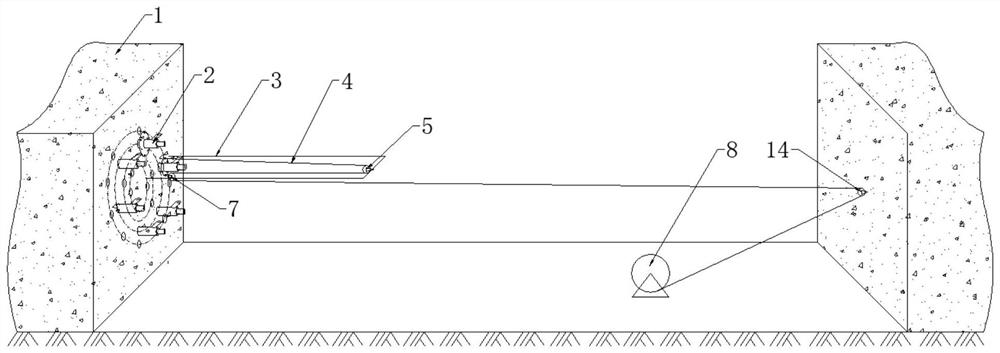

[0039] Such as image 3 and Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that the third fixed pulley 14 is installed on the facade of the ground connection wall structure 1 opposite to the ground connection wall structure 1 where the horizontal freezing tube freezer flange plate 2 to be removed is located. (promptly installed on the facade of the ground wall structure opposite to the ground wall structure 1 where the horizontal freezing pipe freezer flange plate 2 to be removed is located), only the first fixed pulley 5 is installed on the pipe puller support 3 The fourth fixed pulley 15 is not installed. After the steel wire rope 4 is drawn out from the second fixed pulley 7, the distance to the third fixed pulley 14 is relatively large, and the steel wire rope 4 only needs to adjust a small angle to adapt to the horizontal frozen pipe freezer flange 2 to be removed. The change of the relative position on the facade of the connecting wall s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com