A construction method of concrete rainwater well using steel pipe as inner mold

A construction method and technology for rainwater wells, which are applied in waterway systems, water supply devices, drainage structures, etc., can solve the problems of cracking, low compressive strength, and easy falling off of ash joints, so as to reduce costs, facilitate extubation, and prevent concrete from leaking. sprinkle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

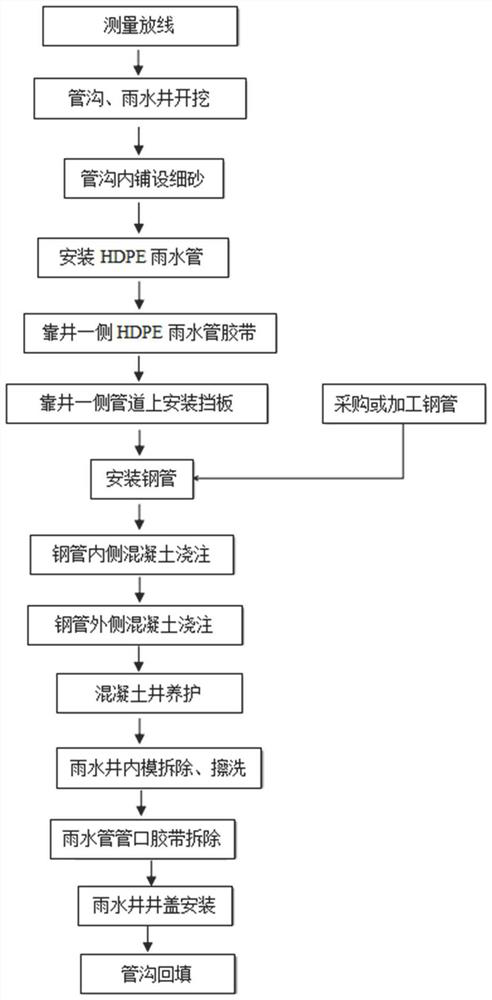

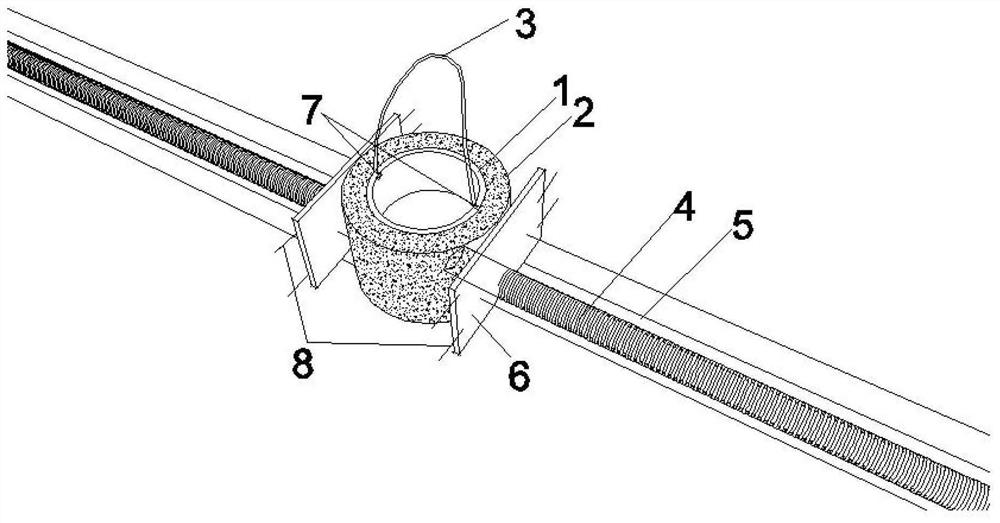

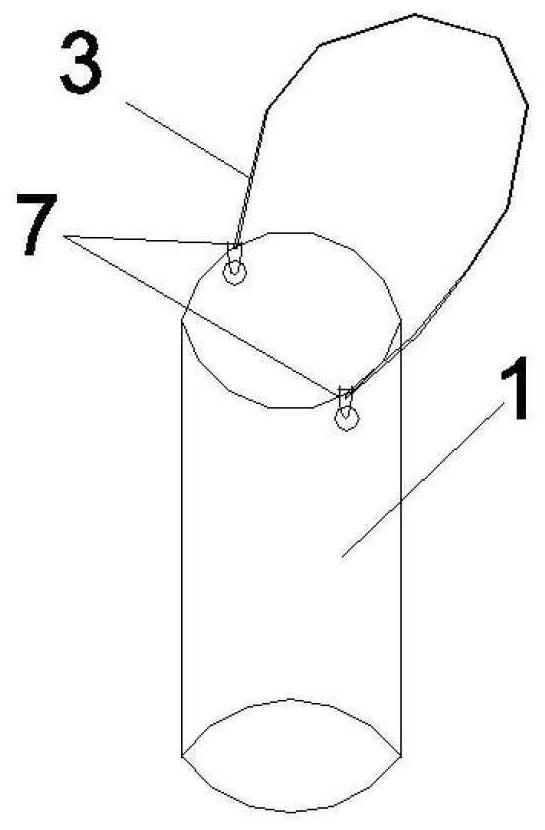

[0040] Such as Figure 1 to Figure 4 Shown, a kind of concrete rainwater well construction method that utilizes steel pipe to make inner formwork is characterized in that, comprises specific following steps:

[0041] Step 1: HDPE rainwater pipe 4 installation

[0042] 1) Measuring and setting out: according to the direction and elevation of the pipeline in the drawing, use lime wire to release the direction and position of the pipeline and tube well respectively; excavate a circular well pit with a diameter of φ1400 at the position of the tube well, and spread lime line at the center of the well pit. On the "ten"-shaped mark, the depth of the well pit should be based on the drawing design plus 100mm as the rainwater well cushion;

[0043] 2) Excavation of pipe trench 5 and rainwater well: according to the design requirements of the construction drawings, use excavator to excavate pipe trench 5 and rainwater well;

[0044] 3) Fine sand laying: The original soil at the rainwat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com