A bleed air arrangement for reducing the dissipation vortex in front of the grate plate

A grate tooth and dissipation technology, which is applied in the field of aero-engines, can solve the problems of low cost and achieve the effects of reducing wind resistance temperature rise, improving cooling effect, and improving cooling quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

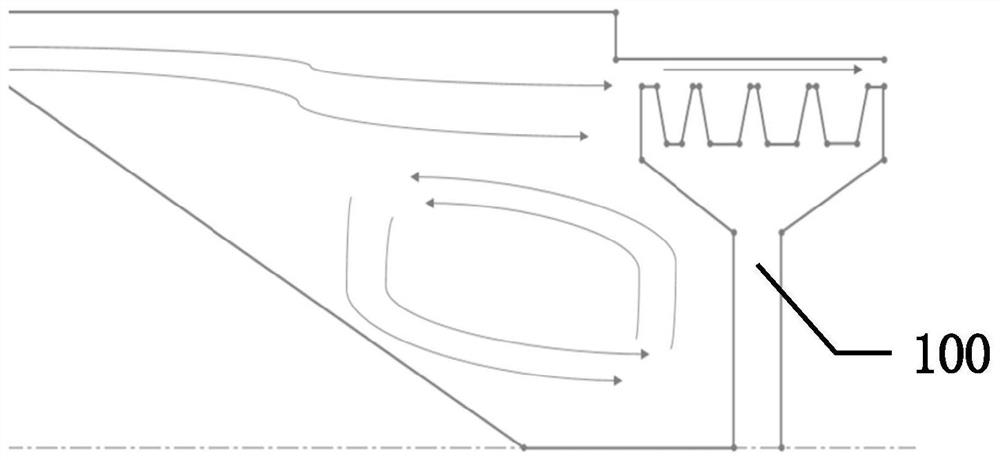

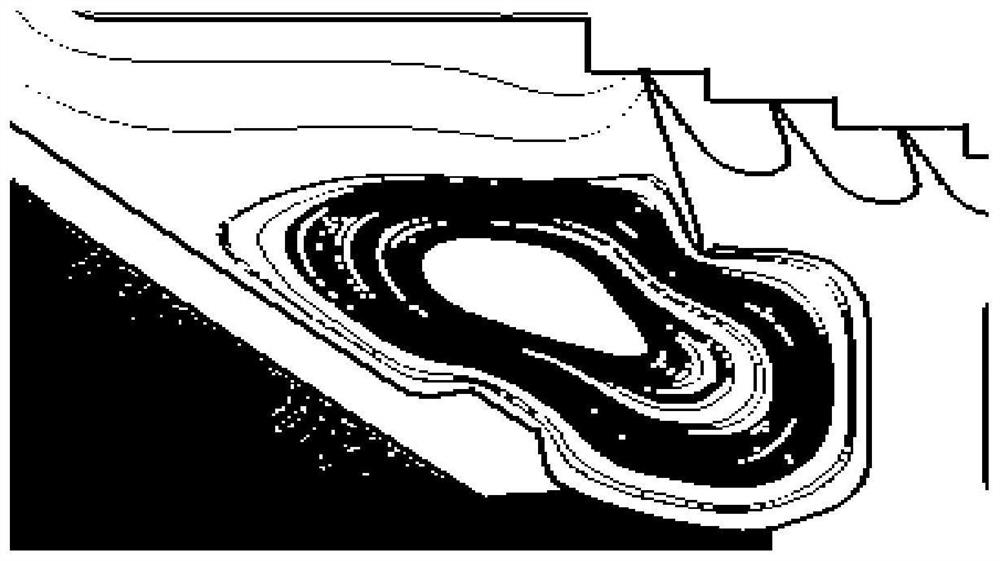

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only for illustration and are not intended to limit the present invention.

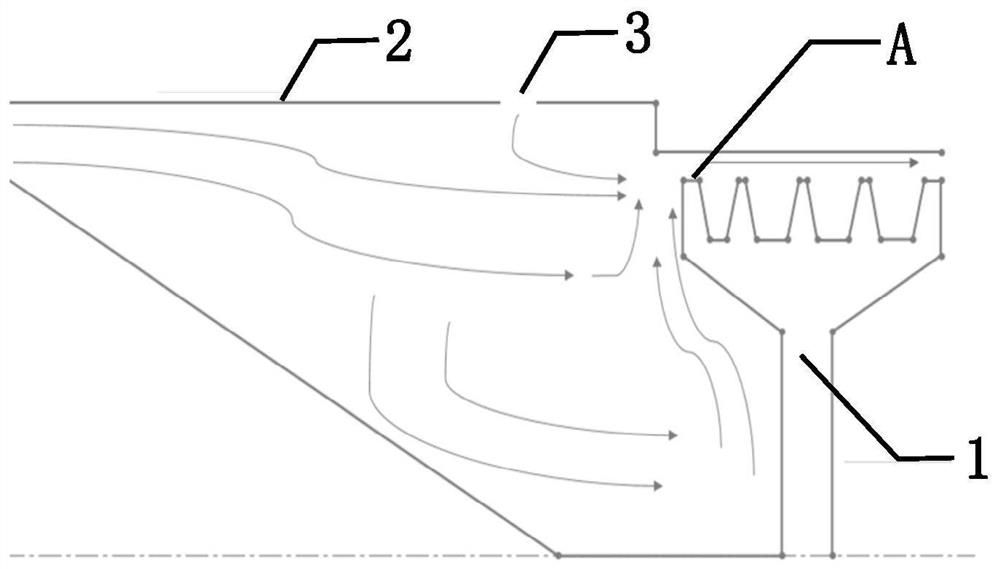

[0021] The invention provides a kind of bleed air layout that weakens the dissipation vortex in front of the grate tooth plate, such as image 3 As shown, on the surface of the stator drum 2 opposite to the grate plate 1, the distance from the first tooth in the grate plate 1 located upstream of the air flow (such as image 3 As shown in A) within the range of 8 mm to 10 mm, a ring of bosses are provided along the circumference of the stator drum surface 2, and a plurality of pre-rotating nozzles are arranged on the bosses as the air inlet 3; since the stator is a thin-walled For thin-walled parts, it is impossible to directly excavate an orifice struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com