A vehicle load learning system and method based on extended power interruption time

A technology of power interruption and learning system, which is applied in the field of vehicle load learning system, which can solve the problems that the slope and load cannot complete self-learning, prolong the power interruption time, etc., and achieve the effect of avoiding the problem of cyclic shifting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

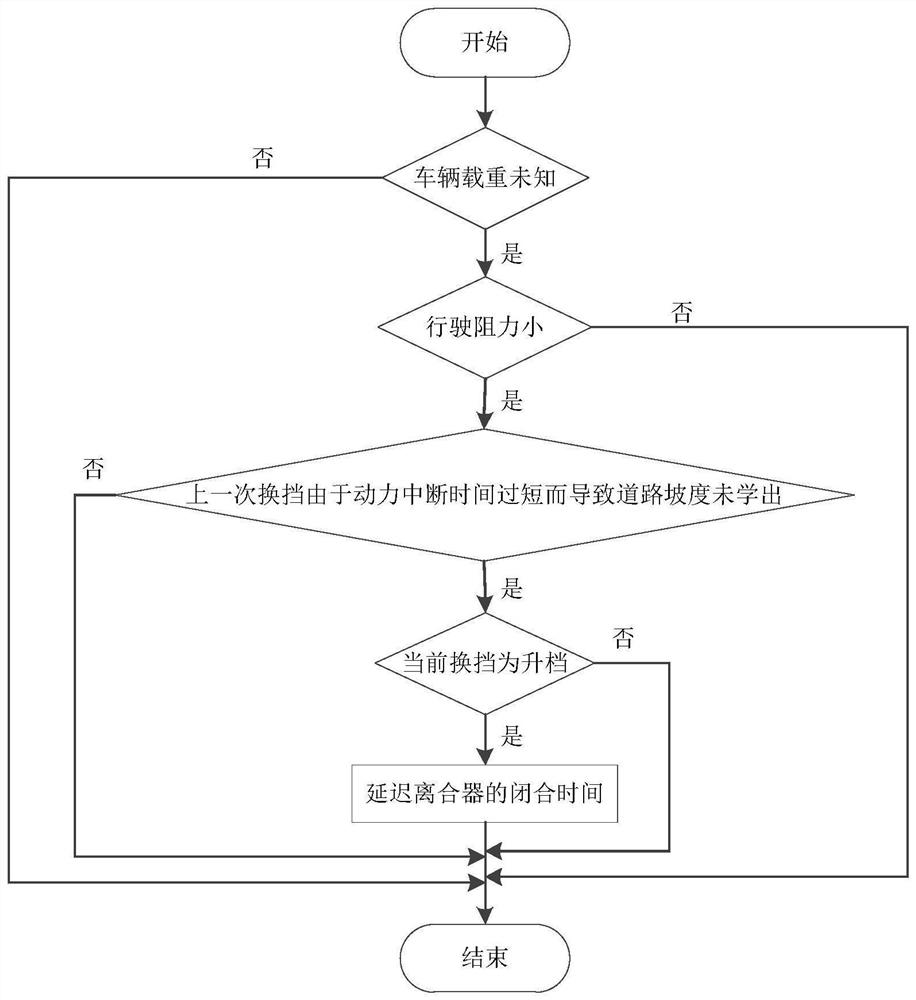

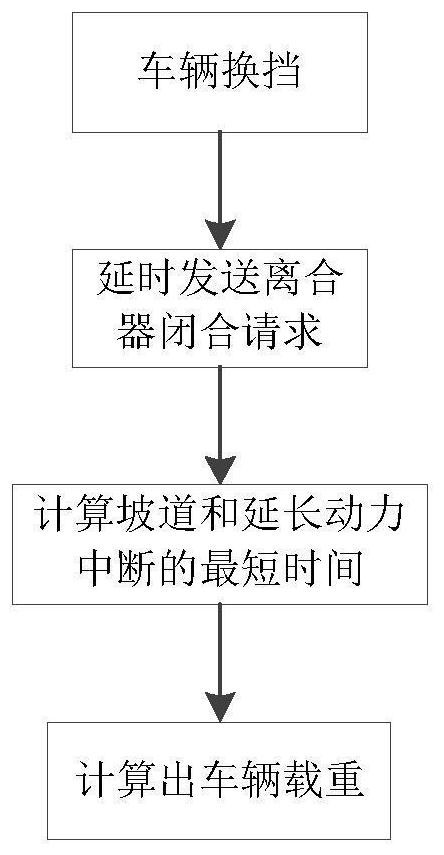

Method used

Image

Examples

Embodiment 1

[0049]In order to verify the feasibility of the present invention, a comparison test is carried out on a 45-ton fully loaded vehicle and an 8-ton empty locomotive respectively, and the test results are shown in Table 1 and Table 2:

[0050] Table 1 Test results of fully loaded vehicle (45 tons)

[0051] Fully loaded truck (45 tons) number of shifts Time from power-on to calculating load driving distance Delay function not activated 26 3m38s 1500m Delay function activation 3 23s 200m

[0052] Table 2 Test results of empty locomotive (8 tons)

[0053] Empty locomotive (8 tons) number of shifts Time from power-on to calculating load driving distance Delay function not activated 28 4m15s 1800m Delay function activation 8 32s 360m

[0054] It can be seen from the table that the system and method of the present invention greatly improves the efficiency of vehicle load calculation. Whether it is a fully loaded...

Embodiment 2

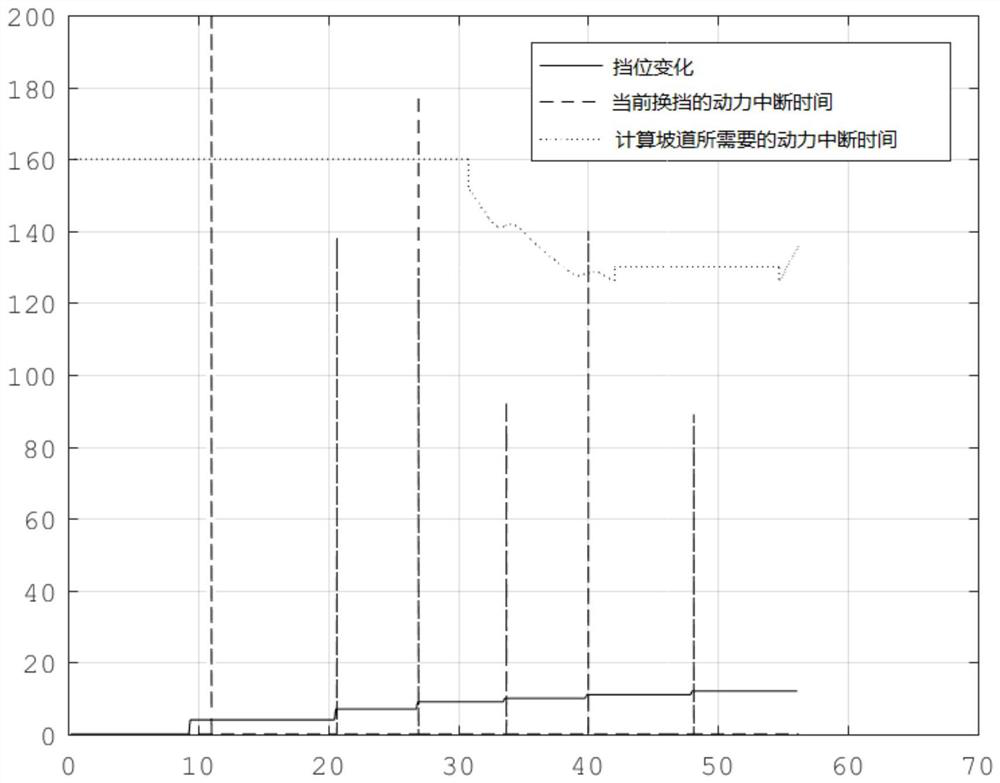

[0056] pass again image 3 and Figure 4 The comparison chart of the present invention further verifies the feasibility of the present invention. The horizontal axis in the figure is the time, and each line segment represents the gear change, the power interruption time of the current gear shift, and the power interruption time required for calculating the ramp; the numbers on the vertical axis are not actual. Meaning, only to distinguish relative sizes.

[0057] from image 3 It is not difficult to find that, after activating the delay function in the system, the power interruption time is prolonged, and the required time can be achieved by two shifts in one acceleration process except for the gear shift. In contrast, in the system without the delay function Figure 4 During the acceleration process, a total of four accelerations were carried out, from the vehicle static to the highest gear. In the first three times, except for the start gear, the power interruption time o...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap