A Brake Difference Monitoring System Based on Pneumatic Brake Response Time

A technology of response time and monitoring system, applied in the direction of braking safety system, etc., can solve the problems of poor deviation control effect and high cost of improvement, and achieve the effect of eliminating potential safety hazards and reducing the amount of calculation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

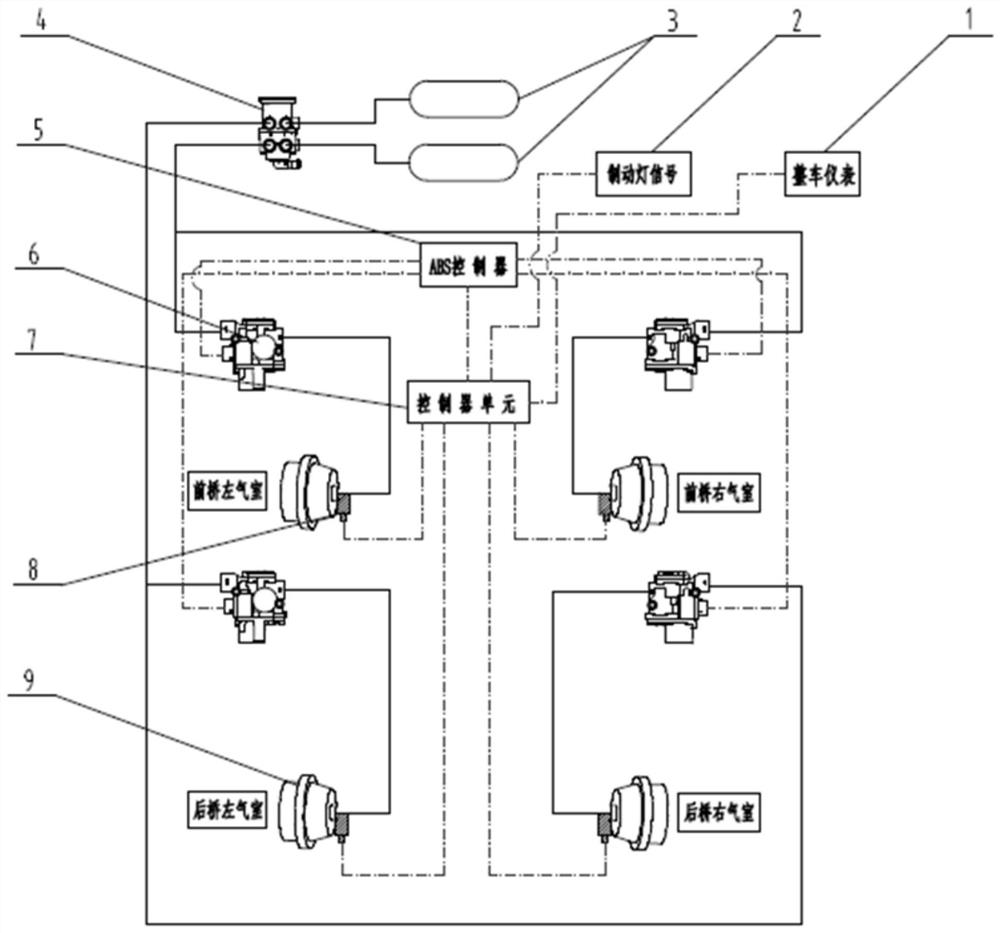

Image

Examples

Embodiment 1

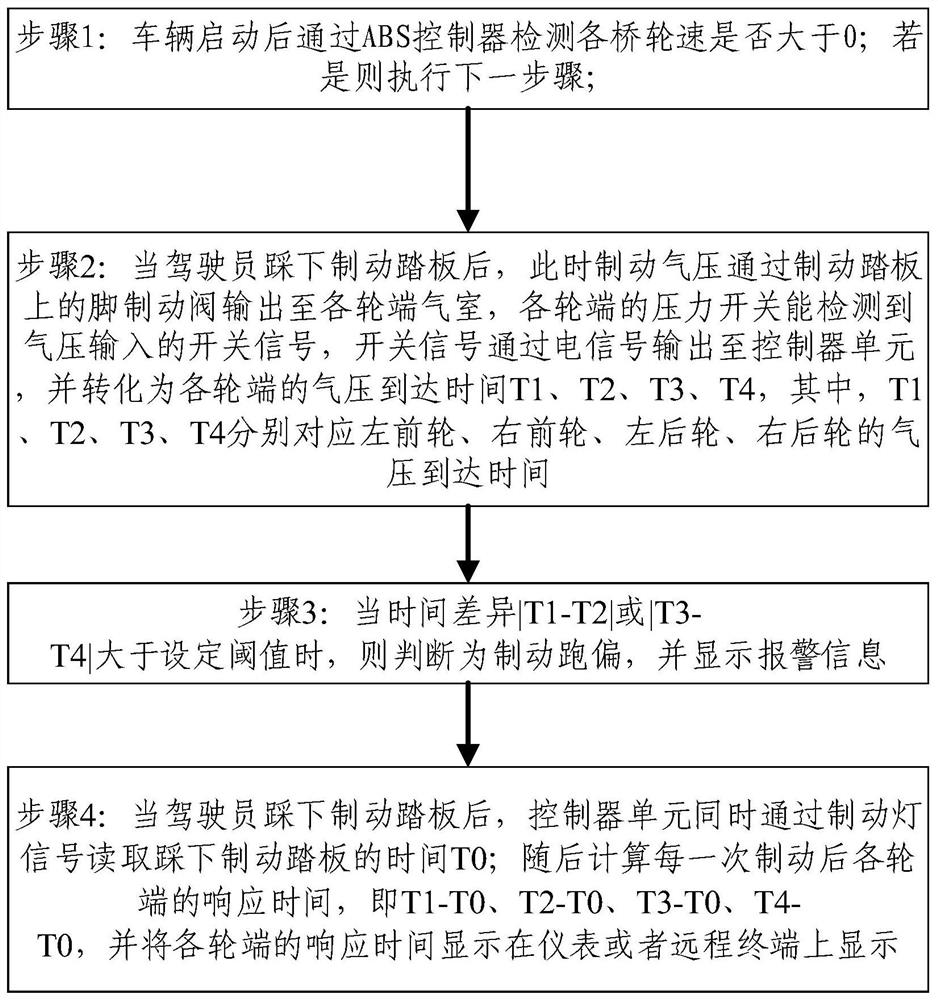

[0046] Such as figure 2 As shown, in order to ensure the consistency of left and right after braking, the lateral left and right difference braking difference monitoring method includes the following steps:

[0047] Step 1: After the vehicle is started, check whether the wheel speed of each axle is greater than 0 through the ABS controller; if so, execute the next step; otherwise, stop executing the program and manually check for hardware problems;

[0048] Step 2: When the driver depresses the brake pedal, the brake air pressure is output to the air chamber at each wheel end through the foot brake valve on the brake pedal, and the pressure switch at each wheel end can detect the switch signal of the air pressure input. The switch signal is output to the controller unit through an electrical signal, and converted into the air pressure arrival time T1, T2, T3, T4 at each wheel end, where T1, T2, T3, T4 correspond to the left front wheel, right front wheel, and left rear wheel ...

Embodiment 2

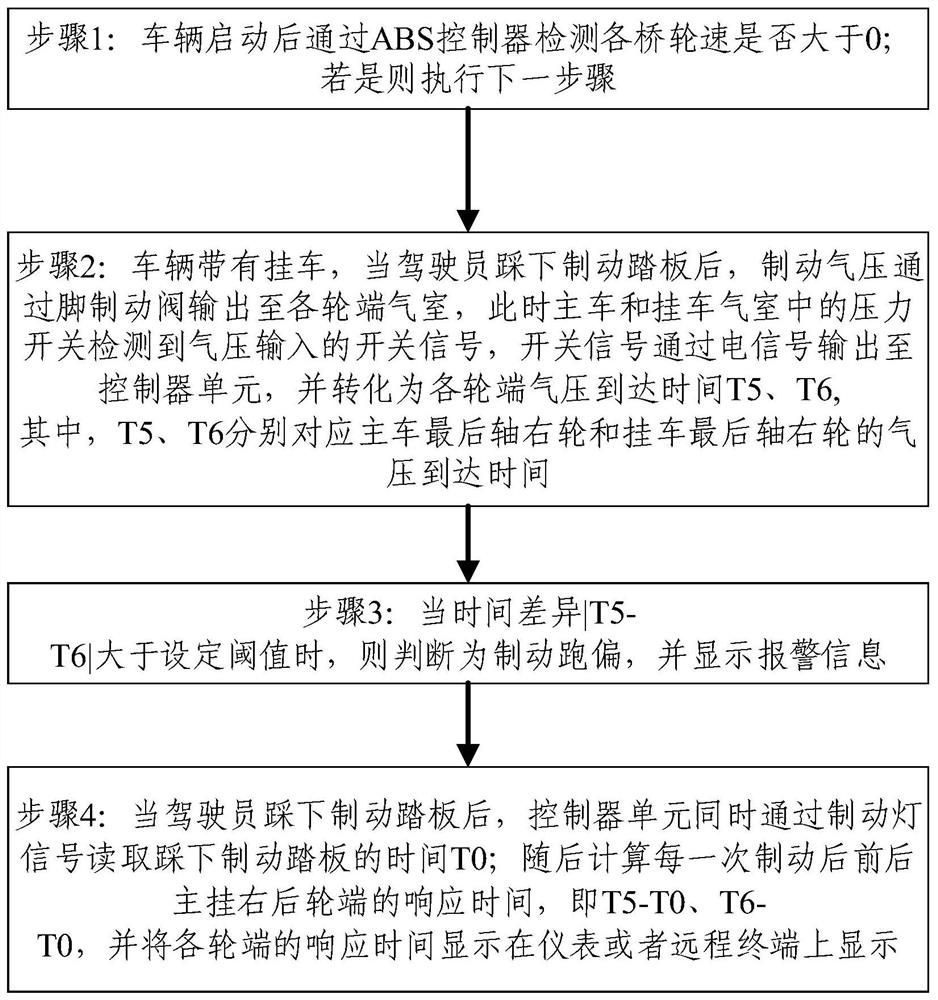

[0060] Such as image 3 As shown, in order to ensure the consistency of the main suspension after braking, the braking difference monitoring method of the front and rear differences of the main suspension includes the following steps:

[0061] Step 1: After the vehicle is started, check whether the wheel speed of each axle is greater than 0 through the ABS controller; if so, execute the next step; otherwise, stop executing the program and manually check for hardware problems;

[0062] Step 2: The vehicle has a trailer (for example: truck or tractor, forklift). When the driver steps on the brake pedal, the brake air pressure is output to the air chamber at the end of each wheel through the foot brake valve. At this time, the main vehicle and the trailer The pressure switch in the air chamber detects the switch signal of the air pressure input, and the switch signal is output to the controller unit through the electrical signal, and converted into the arrival time T5 and T6 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com