A kind of method of alkylanthraquinone hydrogenation

A technology of alkyl anthracene and hydrogenation catalyst, applied in chemical instruments and methods, preparation of hydroxyl compounds, preparation of organic compounds, etc., can solve problems such as shortening service life, affecting catalyst fluidization, affecting catalyst utilization efficiency, etc., and achieves long-term The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

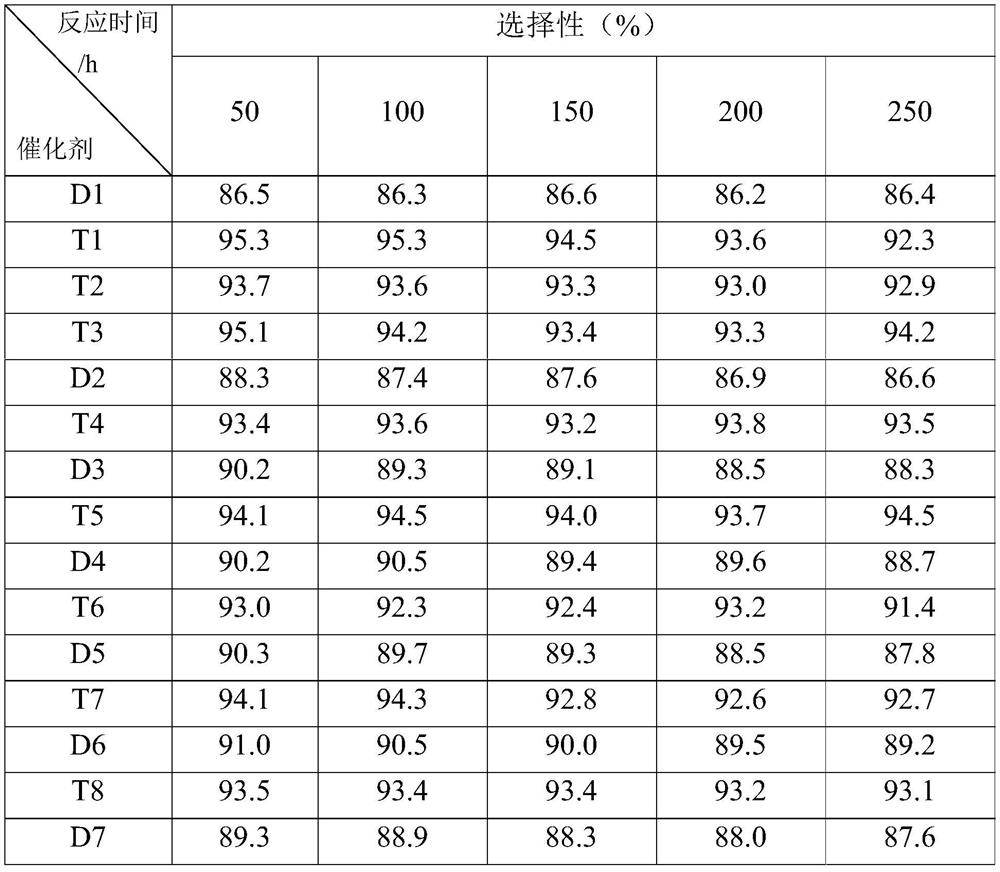

Image

Examples

preparation example Construction

[0019] The preparation method of the hydrogenation catalyst described in the method of the present invention preferably comprises the following steps:

[0020] a. Dry the activated alumina powder and measure the saturated water absorption;

[0021] b. According to P 2 O 5 / Al 2 O 3 The mass ratio of 0.001 to 0.3 is used to calculate the P required for 100g of activated alumina 2 O 5 , and then calculate the corresponding required mass of phosphorus-containing compounds;

[0022] c. Weigh the required amount of deionized water and phosphorus-containing compound, prepare a solution of corresponding phosphorus-containing compound, fully mix with activated alumina, dry, and roast to obtain a carrier;

[0023] D, impregnate the carrier that step c obtains with the solution that contains palladium compound, ruthenium compound and the compound containing co-active component of required amount, and drips NaOH solution to obtain catalyst precursor suspension;

[0024] e. Then pa...

Embodiment 1

[0032] (1) Carrier preparation

[0033] Weigh 100g γ-Al 2 O 3 (Jiangyan City Chemical Auxiliary Factory, Jiangsu Province, with a surface area of 150m 2 / g, the pore volume is 0.4mL / g, the particle size is 30-150μm), the saturated water absorption is determined to be 70mL, according to P 2 O 5 / Al 2 O 3 Weigh 3.25g of ammonium dihydrogen phosphate with a mass ratio of 0.02 and add it to 70mL of deionized water required for weighing to prepare a corresponding ammonium phosphate solution, mix with activated alumina and stir evenly, and then move it into an oven to dry at 120°C for 4h. The dried samples were calcined at 550 °C for 8 h to obtain the desired carrier.

[0034] (2) Catalyst preparation

[0035] Measure 100mL of aqueous solutions with palladium chloride and ruthenium chloride concentrations of 7.5g / L and 7.5g / L respectively, take 75g of the carrier obtained in step (1), disperse the carrier into the above solution, immerse it at room temperature for 12h, drop...

Embodiment 2

[0037] (1) Carrier preparation

[0038] Weigh 100g γ-Al 2 O 3 (Jiangyan City Chemical Auxiliary Factory, Jiangsu Province, with a surface area of 150m 2 / g, the pore volume is 0.4mL / g, the particle size is 30-150μm), the saturated water absorption is determined to be 70mL, according to P 2 O 5 / Al 2 O 3 Weigh 8.2 g of ammonium dihydrogen phosphate with a mass ratio of 0.05 and add it to 70 mL of deionized water required for weighing to prepare a corresponding ammonium phosphate solution, mix with activated alumina and stir evenly, and then move it into an oven to dry at 120 ° C for 4 hours. The dried samples were calcined at 550 °C for 8 h to obtain the desired carrier.

[0039] (2) Catalyst preparation

[0040] Measure 100mL of aqueous solutions with palladium chloride and ruthenium chloride concentrations of 7.5g / L and 7.5g / L respectively, take 75g of the carrier obtained in step (1), disperse the carrier into the above solution, immerse it at room temperature for 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com