An integrated equipment for microbial cultivation

A technology for microbial culture and microbial culture medium, applied in the field of integrated microbial culture equipment, can solve the problems of occupied space, blocked sampling process, harsh temperature, humidity, and cleanliness, etc., and achieve the effect of reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

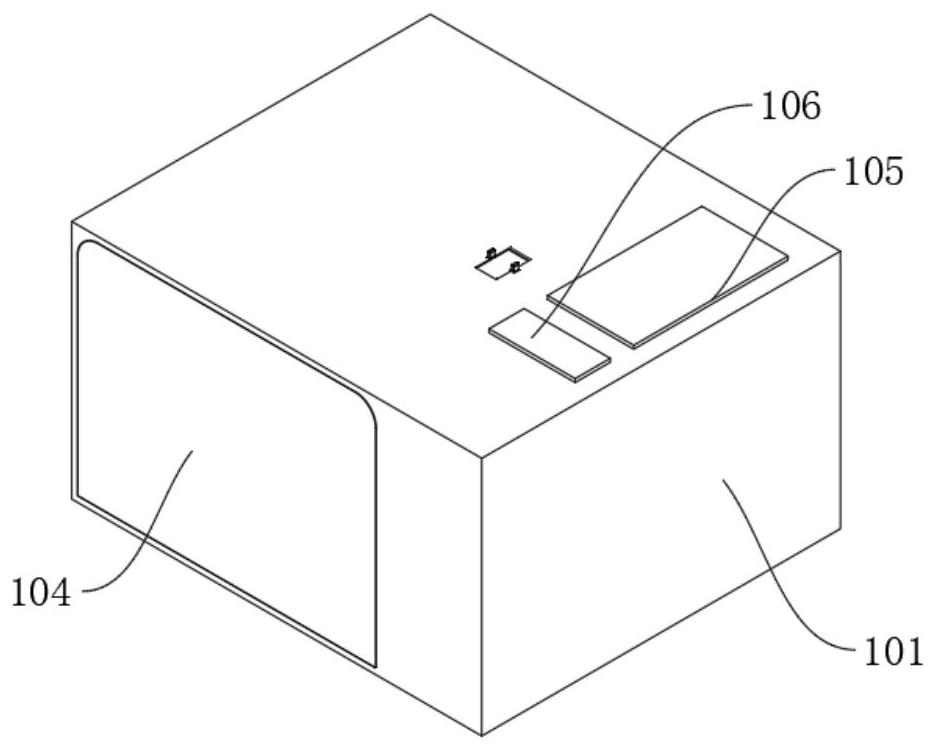

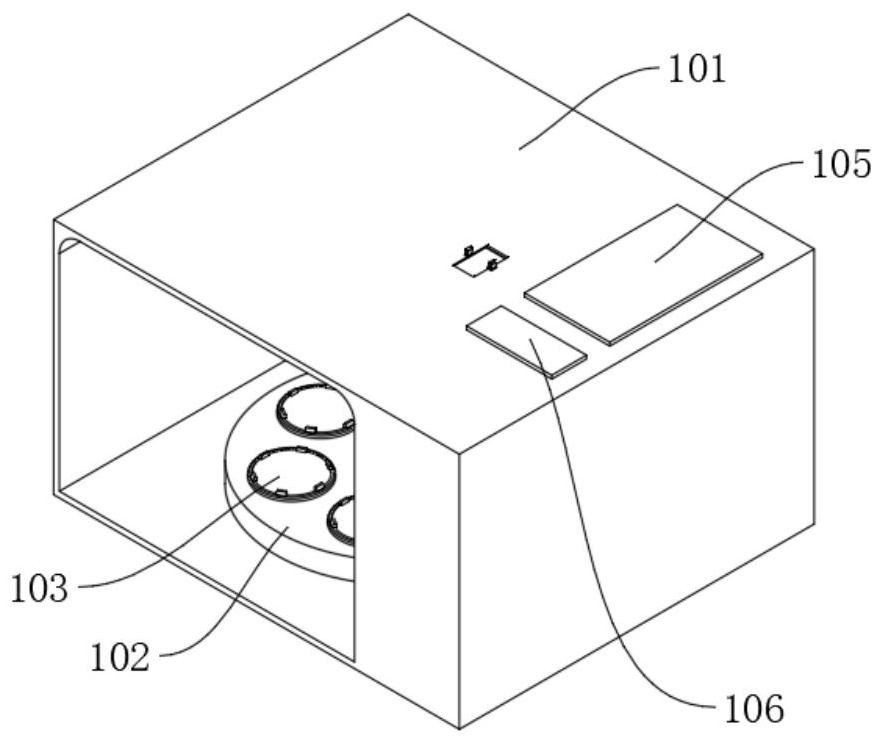

[0027] refer to Figure 1-5 , an integrated equipment for microbial cultivation, comprising: a microbial cultivation chamber 101, a built-in rotating chassis 102 and a built-in rotating base 103, the microbial cultivation chamber 101 is provided with a cavity for placing microbial culture medium and is movable at the bottom of the cavity. Rotating chassis 102, the interior of the built-in rotating chassis 102 is ring-shaped and movable. Six sets of built-in rotating bases 103 are installed. The built-in rotating bases 103 are used to fix and place microbial culture media, and the cavity for placing microbial culture media is provided inside the microbial culture chamber 101. A built-in microbial culture sampling device is movable installed at the position corresponding to the axis center of any set of built-in rotating bases 103. The upper surface of the microbial culture chamber 101 is located at the built-in microbial culture sampling device. There is a sealed revolving door ...

Embodiment 2

[0031] Embodiment 2: Based on Embodiment 1, but different:

[0032] The built-in microbial culture sampling mechanism includes: a fixed frame 301, a linkage sealed door 302, a moving pole 303, a rotating rod 304, a rotating shaft 305, a fixed arc plate 306, a rotary spring 307 and a hydraulic rod 308. There are hydraulic rods 308 fixedly installed on the left and right sides inside the culture chamber 101. The lower ends of the hydraulic rods 308 are fixedly connected to the outer surfaces of the left and right sides of the middle of the fixed frame 301. The fixed frame 301 is divided into an inlet area, a fixed area and a sampling area from top to bottom. The left and right sides of the inside of the fixed frame 301 are movably socketed with movable struts 303, the upper end of the movable struts 303 is movably connected with the middle part of the lower surface of the upper linkage airtight door 302, and the outer side of the upper linkage airtight door 302 is connected with ...

Embodiment 3

[0035] Embodiment 3: Based on Embodiment 1 and 2, but different:

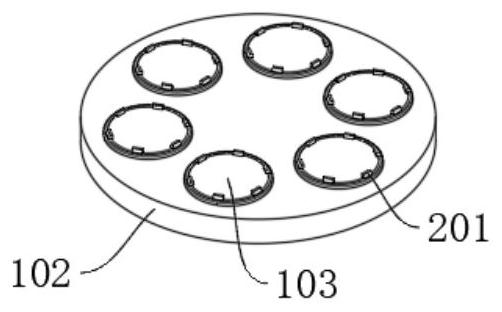

[0036] The built-in rotating base 103 is provided with multiple groups of moving grooves 203 in a ring shape away from the axis. The moving groove 203 is equipped with a fixed buckle 201. The outer side of the fixed buckle 201 is fixedly connected with one end of the fixed spring 202. The fixed spring The other end of 202 is fixedly connected with the inner wall of the moving tank 203 .

[0037] The fixed buckle 201 is provided on the built-in rotating base 103. During the process of placing the culture dish, the culture dish can be fixed on the built-in rotating base 103 by simply pressing down on the culture dish to prevent position deflection during the rotation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com