A connection structure of the damping ring and the pole piece of a solid magnetic pole salient pole synchronous motor

A synchronous motor, solid magnetic pole technology, applied in the direction of structural connection, electric components, electrical components, etc., can solve the problems of easy generation of sparks, motor repair, melting, etc., to achieve the effect of firm and reliable connection, offset centrifugal force, and sufficient contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

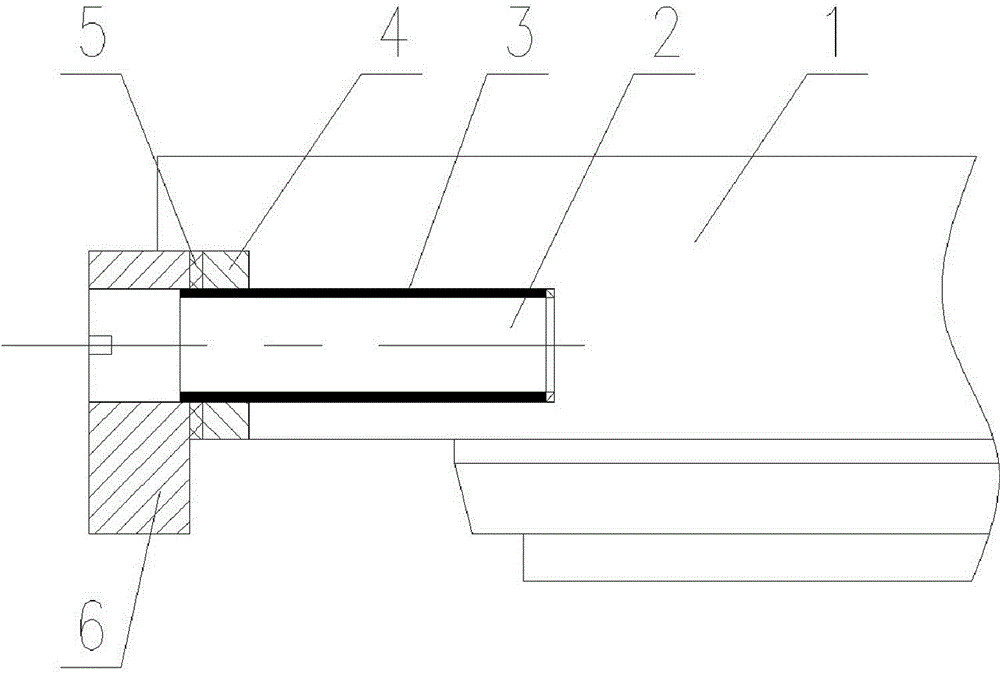

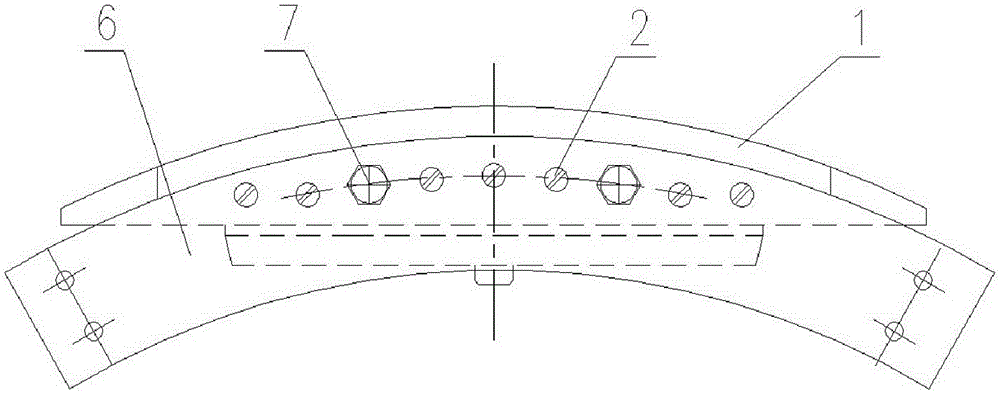

[0012] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. A connection structure between a solid magnetic pole salient pole synchronous motor damping ring and a pole shoe includes a pole shoe 1, a conductive connecting screw 2, a conductive paste 3, a copper layer 4, Silver copper solder piece 5, damping ring 6, bolt 7. Process the end face of the pole shoe 1 into a flange and the contact surface with the damping ring 6, weld the copper layer 4 on the contact surface of the pole shoe 1 by welding process, and process the surface of the copper layer 4 to be smooth And guarantee a thickness of 3mm to 5mm. A number of screw holes are processed on the end face of the pole shoe 1 with the copper layer 4, and the conductive paste 3 is applied to the threaded surface of the conductive connecting screw 2, and the threaded end of the conductive connecting screw 2 is tightened on the screw on the end face of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com