Water tank hoisting device for water tower and construction method of water tank

A hoisting device and water tank technology, applied in the direction of transportation and packaging, load hanging components, formwork/formwork/work frame, etc., can solve the problems of waste of human resources during the construction period, affect the quality of the project, shaking, etc., and save manpower and construction period Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

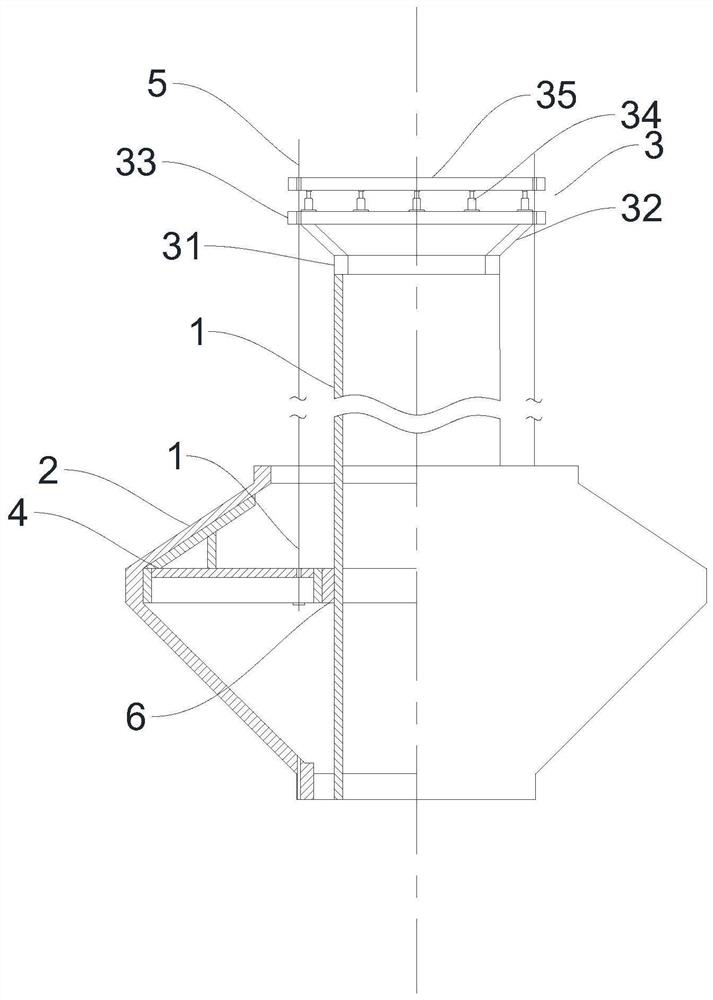

[0032] In this example, if figure 1 As shown, a water tank hoisting device for a water tower includes a support tube 1 and a water tank 2. The support tube 1 is made by a sliding form construction method. The water tank 2 is installed on the top of the support tube 1 through a hoisting device. The hoisting device includes a lifting device 3 and a stable device 4, and the lifting device 3 and the stabilizing device 4 are connected by several steel strands 5, the lifting device 3 is installed on the top of the support tube 1, and the stabilizing device 4 is installed between the support tube 1 and the water tank 2, the hoisting device of the present invention A stabilizing device 4 is provided, which can effectively prevent the water tank 2 and the support tube 1 from being damaged due to collision during the hoisting process, thereby affecting the project quality and causing potential safety hazards;

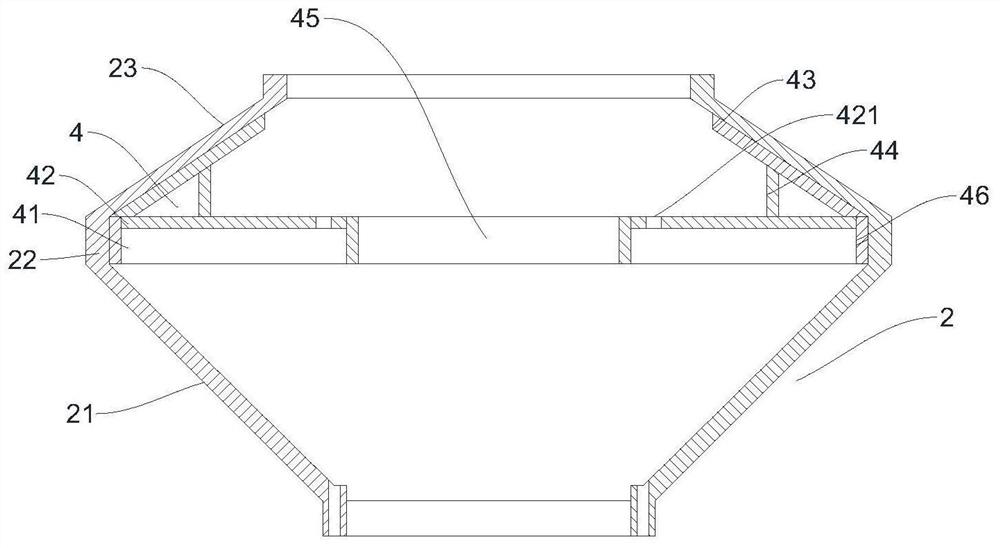

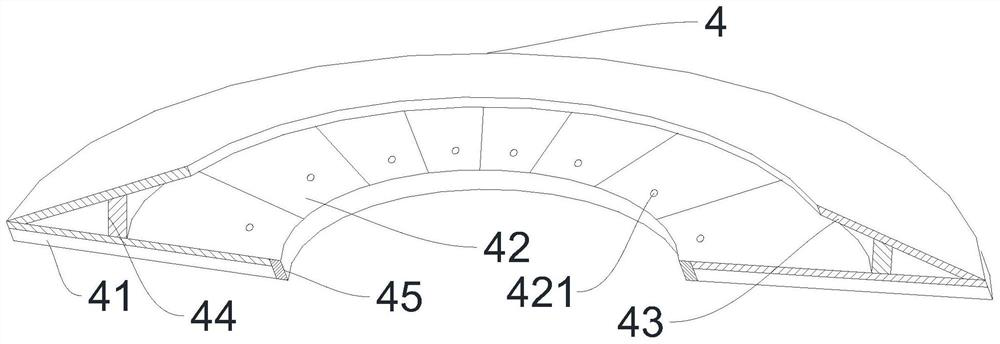

[0033] In this example, if Figure 1~4 As shown, the stabilizing device 4 i...

Embodiment 2

[0036] In this example, if Figure 1~4 As shown, the present embodiment increases the first vertical support 42 on the basis of the first embodiment, and several first vertical supports 41 are also arranged between the outer wall of the inner steel ring 45 and the inner wall of the outer steel ring 46. 41 are evenly distributed on the bottom of the annular plate 42, and the first vertical support 42 is used to strengthen the connection between the inner steel ring 45, the outer steel ring 46 and the annular plate 42. At the same time, when the steel strand 5 lifts the annular plate 42, Reinforce the annular plate 42 to prevent the annular plate 42 from being damaged when the water tank 2 is hoisted due to insufficient rigidity.

Embodiment 3

[0038] In this example, if figure 1 As shown, this embodiment adds a filling layer 6 on the basis of the second embodiment, the filling layer 6 is arranged between the inner steel ring 45 and the support tube 1, and the filling layer 6 is installed on the inner steel ring 45 for further buffering impact force, while avoiding direct contact friction between the inner steel ring 45 and the support tube 1, contacting and damaging the surface of the support tube 1, therefore, the filling layer 6 should be selected to be lower in strength, hardness and stiffness than the support tube 1 and the inner steel ring 45 The material is made of a material with strong wear resistance. Specifically, the support tube 1 is made of concrete, and the inner steel ring 45 is made of Q235-B material. Preferably, the filling layer 6 is made of polytetrafluoroethylene.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com