A processing and positioning method of cooling air film hole of aero-engine flame tube

An aero-engine and positioning method technology, which is applied in the direction of combustion methods, air transportation, climate sustainability, etc., can solve the problems of low yield, large error, time-consuming and labor-intensive, etc., to improve clamping efficiency, avoid positioning errors, The effect of facilitating subsequent removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

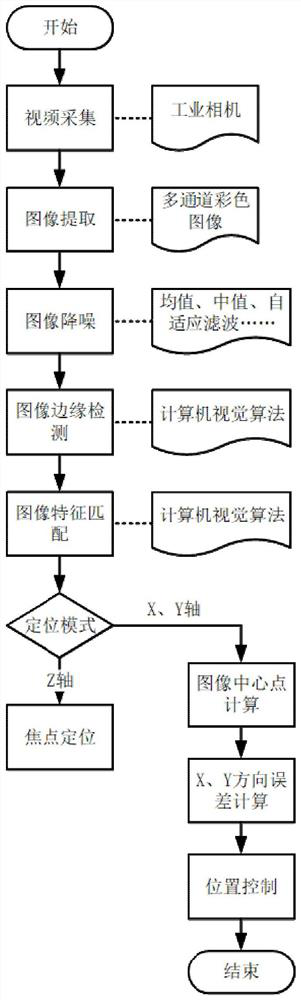

[0036] The precise positioning and processing of the cooling gas film holes of the flame tube are carried out according to the following steps:

[0037] 1) Flame collet mounting

[0038] The flame tube is mounted on a special fixture, which is specially designed and customized.

[0039] 2) Theoretical coordinate acquisition

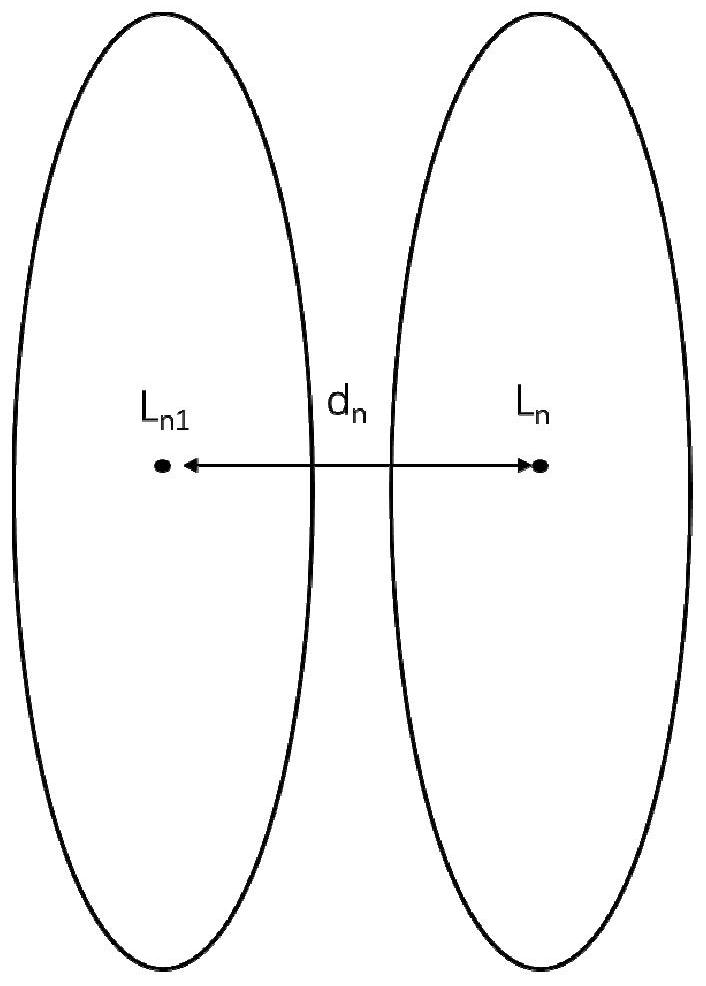

[0040] According to the UG model of the actual flame tube, the theoretical three-dimensional coordinates of the gas film holes of the flame tube in the world coordinate system are obtained; the three-dimensional hole position coordinates of all the gas film holes on the flame tube in the world coordinate system (X ,Y,Z); where the nth hole coordinate is represented by (X n ,Y n ,Z n ) calibration, n represents the machining sequence of the holes.

[0041] 3) Spray developer

[0042] Evenly spray a thin layer of white contrast-enhancing developer on the surface of the flame barrel.

[0043] 4) Pre-mark dots

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com