A method, device and system for online detection of mass flow rate of high temperature fluid

A high-temperature fluid and mass flow technology, which is applied to mass flow measurement devices, indirect mass flow meters, etc., can solve the problems of low detection accuracy of high-temperature fluid mass flow and achieve real-time accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

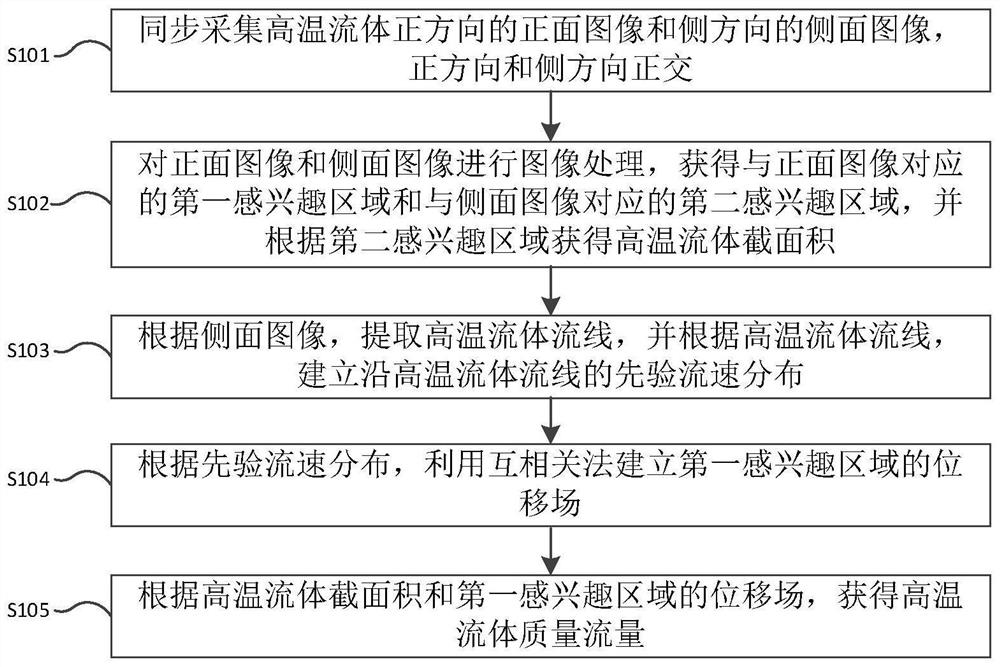

[0066] refer to figure 1 , the online detection method of high-temperature fluid mass flow rate provided by Embodiment 1 of the present invention, comprising:

[0067] Step S101, synchronously collect the frontal image of the high-temperature fluid in the forward direction and the lateral image in the lateral direction, and the forward direction and the lateral direction are orthogonal;

[0068] Step S102, performing image processing on the front image and the side image, obtaining a first region of interest corresponding to the front image and a second region of interest corresponding to the side image, and obtaining a cross-sectional area of the high-temperature fluid according to the second region of interest;

[0069] Step S103, extracting high-temperature fluid streamlines according to the side image, and establishing a priori flow velocity distribution along the high-temperature fluid streamlines according to the high-temperature fluid streamlines;

[0070] Step S104,...

Embodiment 2

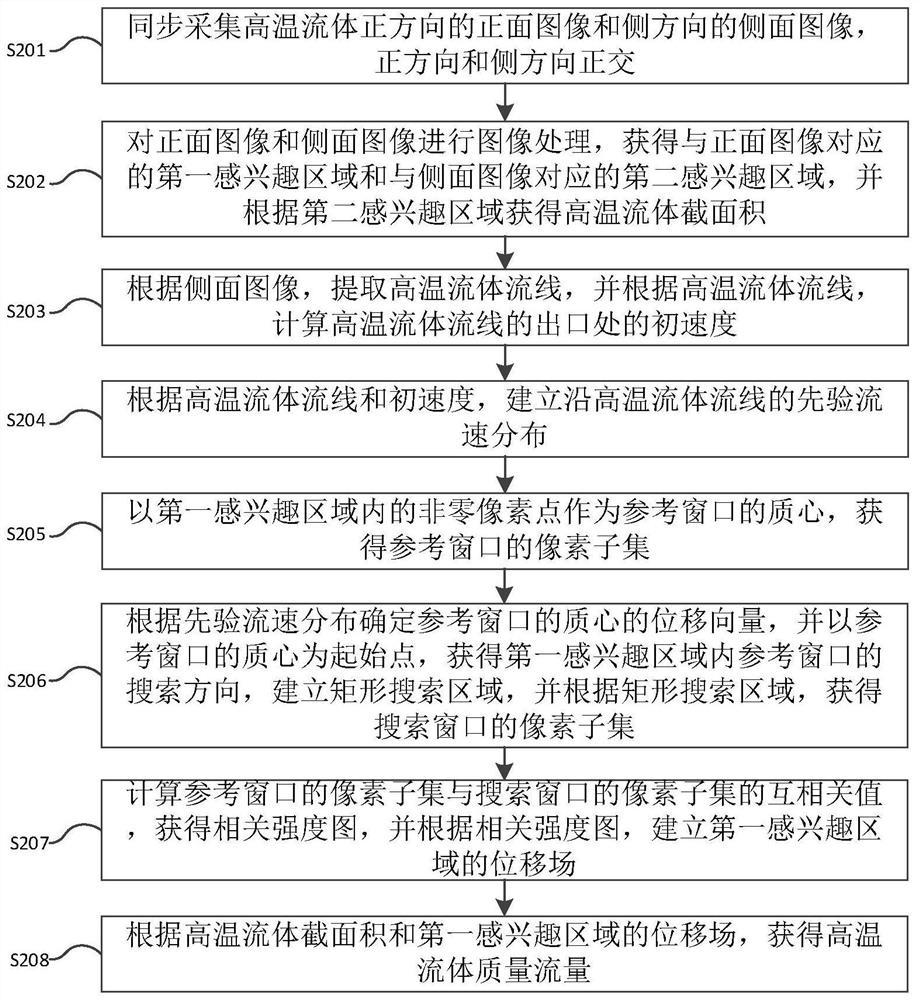

[0075] refer to figure 2 , the online detection method of high-temperature fluid mass flow rate provided by Embodiment 2 of the present invention, comprising:

[0076] Step S201, synchronously collect frontal images of the high-temperature fluid in the forward direction and lateral images in the lateral direction, and the forward direction and the lateral direction are orthogonal.

[0077] Specifically, in this embodiment, the front camera captures the frontal image corresponding to the positive direction of the high-temperature fluid, and the side camera captures the side image corresponding to the side direction of the high-temperature fluid, and the installation position of the front camera is orthogonal to the installation position of the side camera. When collecting frontal and side images in this embodiment, first determine the type selection of the industrial dual camera (i.e., the front camera and the side camera), install and fix the industrial dual camera on site an...

Embodiment 3

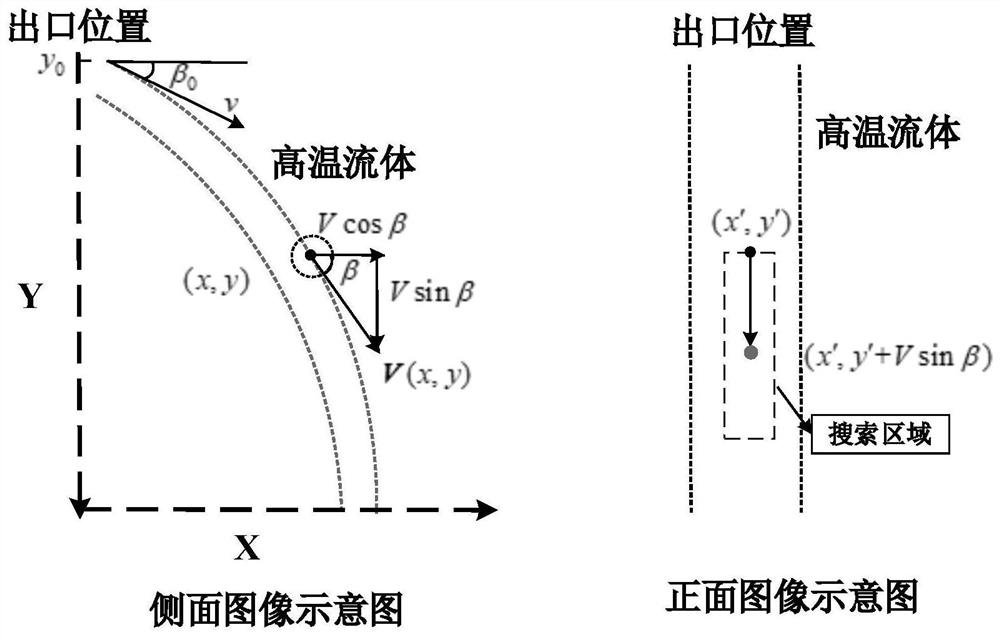

[0125] combined with Figure 4 And attached Figure 5 The situation of the specific embodiment of the present invention is further described, and the present invention is applied to a certain 2650m in China 3 On the blast furnace, in the casthouse on the blast furnace, all in accordance with image 3 with Figure 4 Installation method Install dual cameras. There are harsh environments such as high temperature and high dust on site. In order to ensure the stable operation of the dual cameras, it is necessary to install a protection device for the dual cameras. Specifically, the protection device uses air cooling to isolate a large amount of external heat radiation and take away the heat emitted by the dual cameras. The steps of specific implementation are as follows:

[0126] (1) According to the installation parameters of the dual cameras and field data, the cameras are calibrated to determine the relationship between the image coordinate system and the world coordinate sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com