Thermocompression bonders, methods of operating thermocompression bonders, and interconnect methods for fine pitch flip chip assembly

A technology of thermocompression bonding and bonding head, which can be used in electric heating devices, metallurgical bonding, electric solid devices, etc., and can solve the problem of time-consuming removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

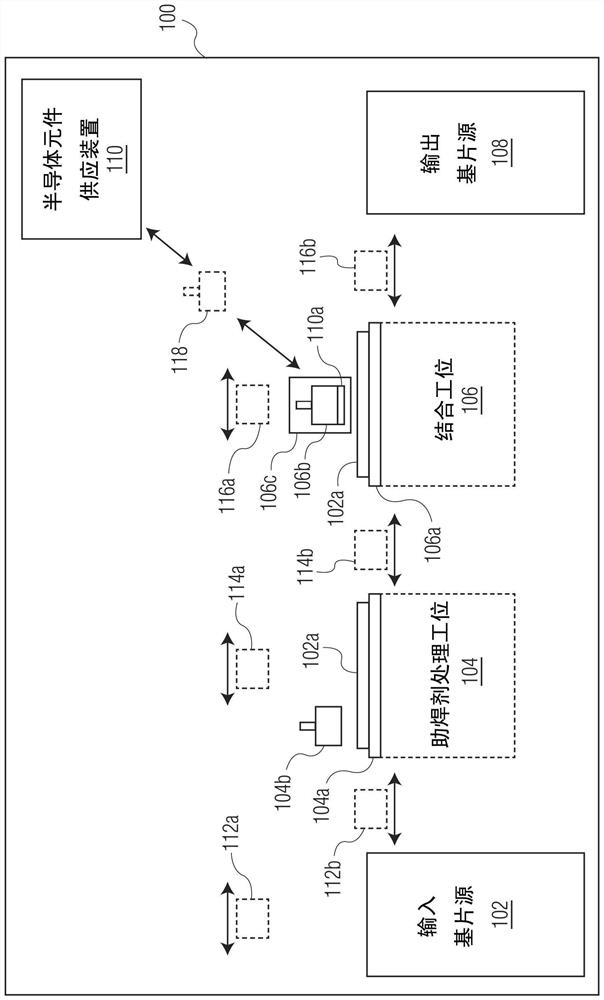

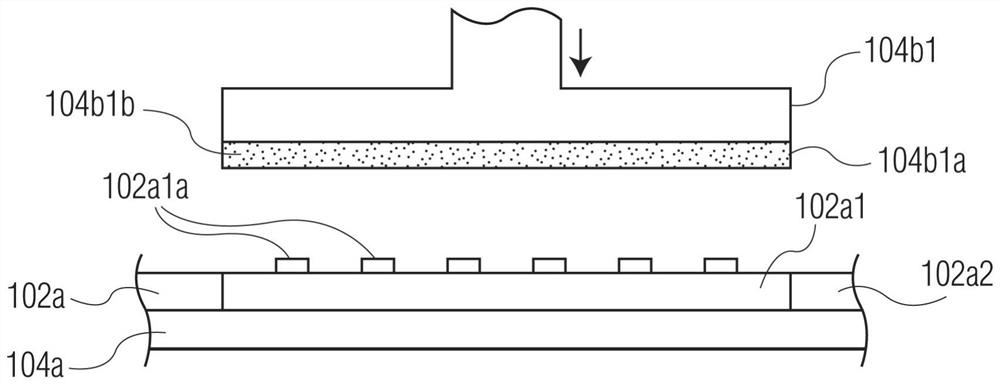

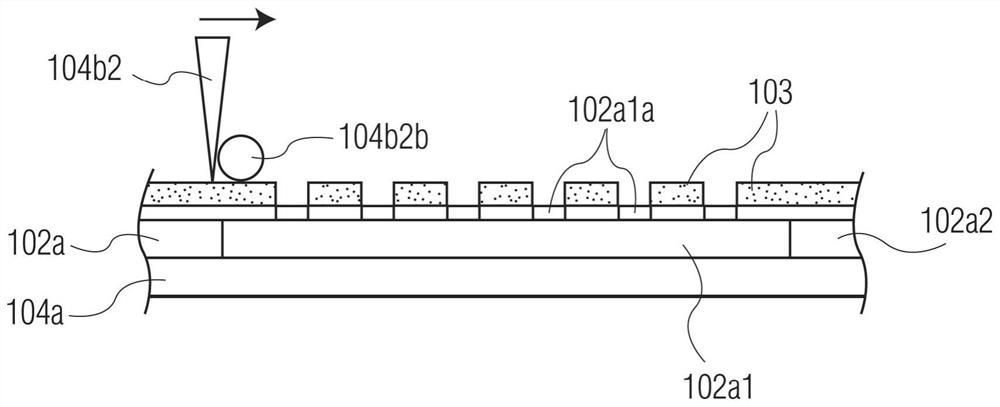

[0038] As used herein, the term "semiconductor element" means any structure that contains (or is constructed to contain in a subsequent step) a semiconductor chip or die. Exemplary semiconductor components include bare semiconductor dies, semiconductor dies on substrates (e.g., lead frames, PCBs, carriers, semiconductor chips, semiconductor wafers, BGA substrates, semiconductor components, etc.), packaged semiconductor devices, flip-chip Semiconductor devices, dies embedded in substrates, stacks of semiconductor dies, interposers (eg, glass or silicon substrates with fine pitch circuitry), and the like.

[0039] As used herein, the terms "substrate" and "workpiece" mean any structure to which a semiconductor element can be bonded (eg, thermocompression bonded, etc.). Illustrative substrates include, for example, lead frames, PCBs, carriers, semiconductor chips, semiconductor wafers, BGA substrates, semiconductor components, interposers (eg, glass or silicon substrates with fin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com