Partitioned spring mattress and packaging method thereof

A packaging method and mattress technology, applied in the field of mattresses, can solve the problems that mattress packaging cannot be loaded into large retailers, spiral threads cannot be folded or coiled, and mattresses cannot be coiled, so as to broaden sales channels, The effect of small package size and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

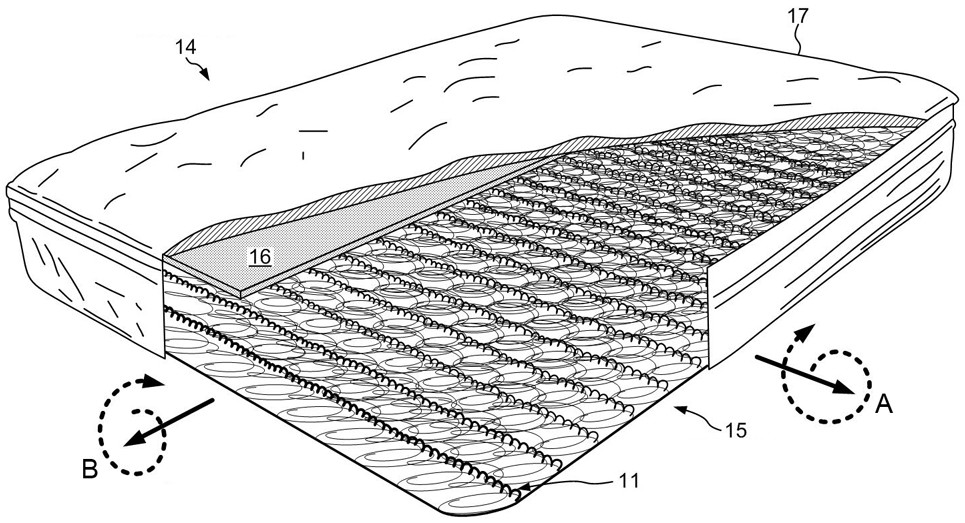

[0052] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. It should be noted that the horizontal direction in this application refers to the direction along the width of the mattress, the longitudinal direction refers to the direction along the length of the mattress, and the center line refers to the line extending along the lateral direction of the mattress that can divide the mattress in half. The center line does not have an entity present in mattresses.

[0053] Figure 4 is a schematic cross-sectional view of the foldable and coiled zoned box spring mattress 20 of the present invention. Mattress 20 comprises a partitioned spring layer 21, a sponge layer 22 and a mattress cover 23, the upper sponge layer 22 is located between the mattress cover 23 and the spring layer 21, and the mattress cover 23 wraps the upper sponge layer 22 and spring layer 21. The upper surface 28 of the spring layer 21 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com