Circumferential clamping type glue and color paste mixing device

A mixing device and glue technology, applied in the field of color paste, can solve the problems of air bubbles, low use effect, uneven mixing of color paste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

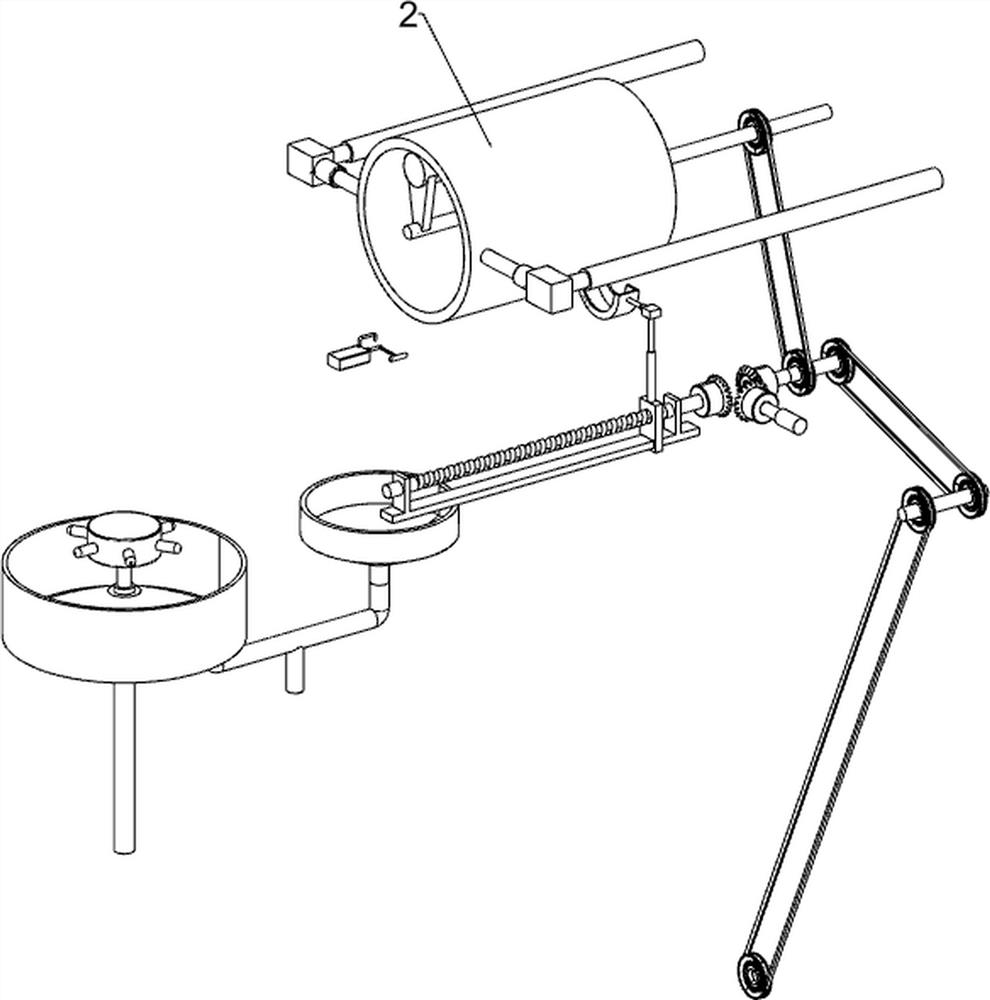

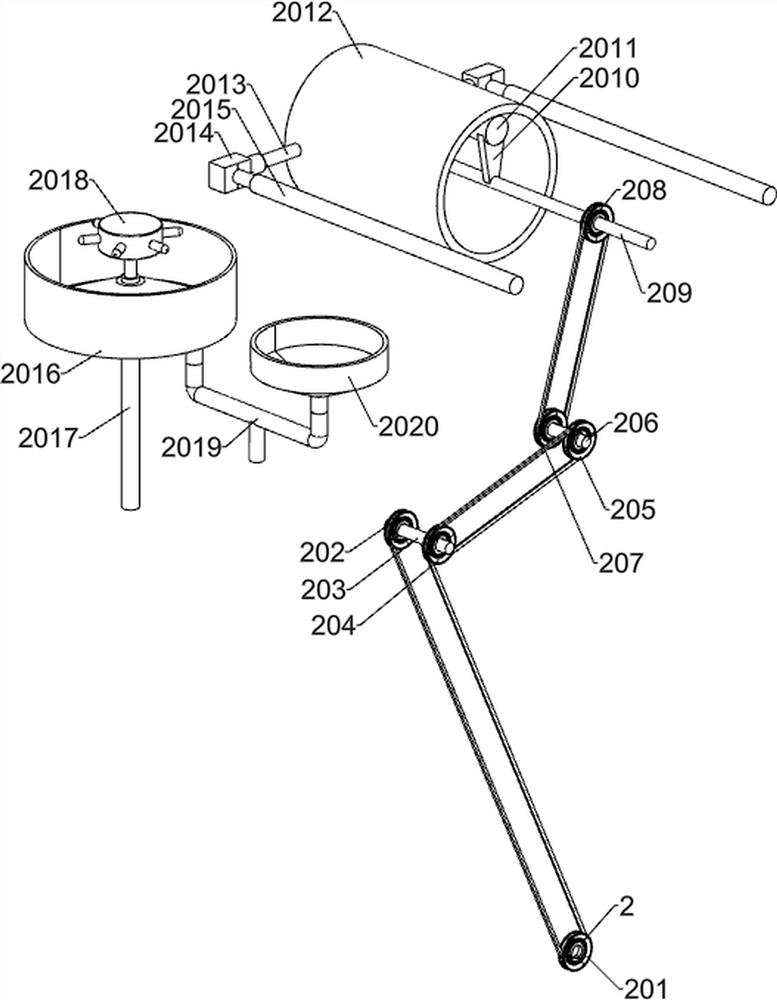

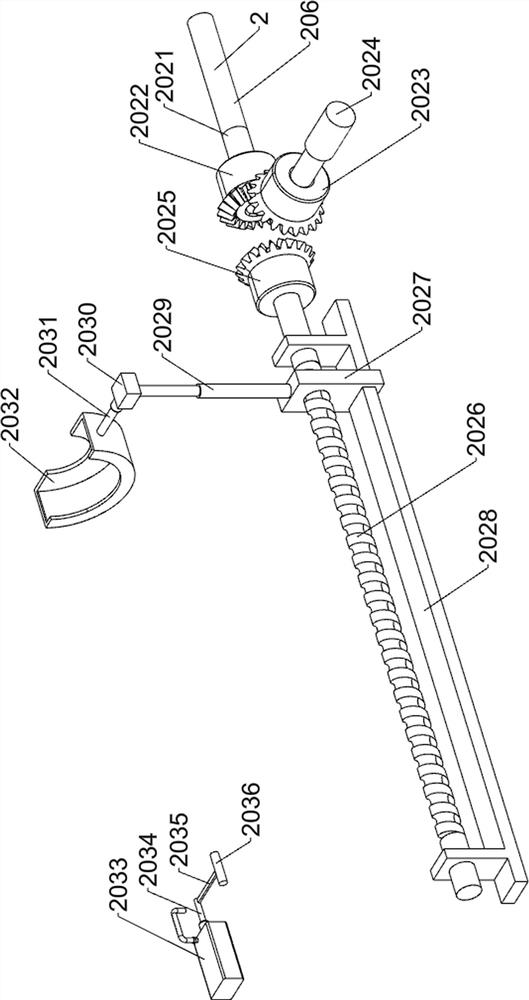

[0029] A kind of circumferential cladding type glue color paste mixing device, such as Figure 1-9 As shown, it includes a bottom frame 1, a mixing assembly 2, a stirring assembly 3, a bubble removal assembly 4 and a control panel 5; the bottom frame 1 is connected with the mixing assembly 2; the bottom frame 1 is connected with the stirring assembly 3; the bottom frame 1 is connected with the mixing assembly 3; The bubble removal component 4 is connected; the bottom frame 1 is connected with the control panel 5; the mixing component 2 is connected with the stirring component 3 .

[0030] When preparing for work, fix the device on a horizontal surface, turn on the power, put an appropriate amount of white color paste into the mixing component 2, and then manipulate the control panel 5 on the chassis 1 to start operation, and the mixing component 2 will mix the white color paste Fully smooth it to the circumferential surface, then put an appropriate amount of color paste into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com