Gear ring combination of mechanical pulverizer

A pulverizer and ring gear technology, which is applied to mechanical equipment, components with teeth, belts/chains/gears, etc., can solve the problems that the pulverizer cannot pulverize and stick, and achieve strong pulverization shear force and pulverization temperature low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with embodiment, but protection scope of the present invention is not limited to this:

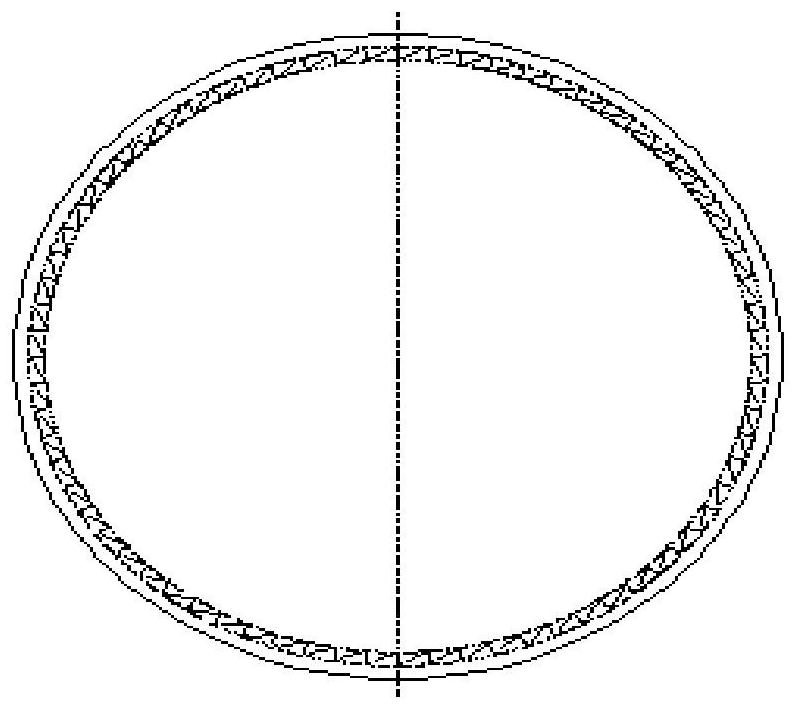

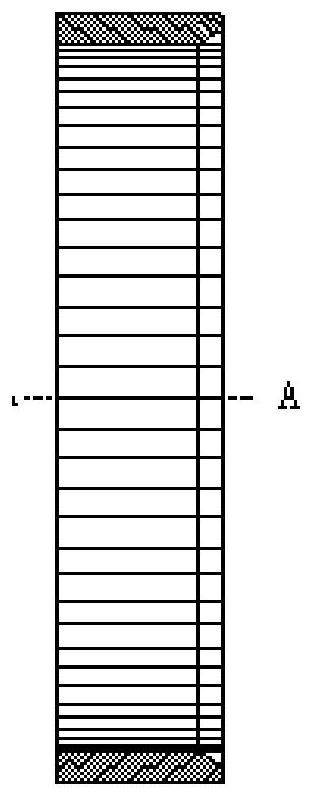

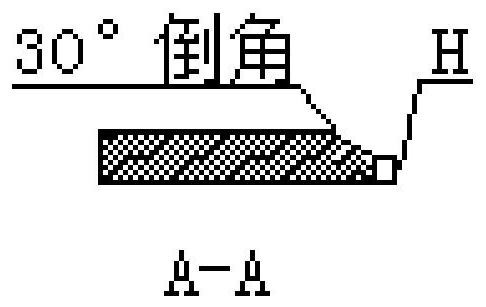

[0023] like Figure 1~5 , a ring gear combination of a mechanical pulverizer, the ring gear combination includes a casing ring gear and a combination of an optical cone ring that is close to the casing ring gear, and the casing ring gear is provided with a A number of gear teeth, each gear tooth is provided with a chamfer a of 10-40° at the height H, the light cone is provided with a chamfer a of 10-40° at the height H, and the housing The ring gear and the cone form a shear angle. The height H is 1 / 5-1 / 3 of the height of the gear teeth or the light cone. The ring gear assembly is located in the inner cavity of the pulverizing chamber of the pulverizer. The inner cavity corresponding to the ring gear of the housing is also provided with a rotary knife swing device, and the rotary knife swing device is driven by ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap