Crushing structure of anti-sticking crusher

A pulverizer and anti-sticking technology, applied in grain processing and other directions, can solve the problems that pulverizers cannot be pulverized and adhered, and achieve the effects of low noise, high pulverization output, and no environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with embodiment, but protection scope of the present invention is not limited to this:

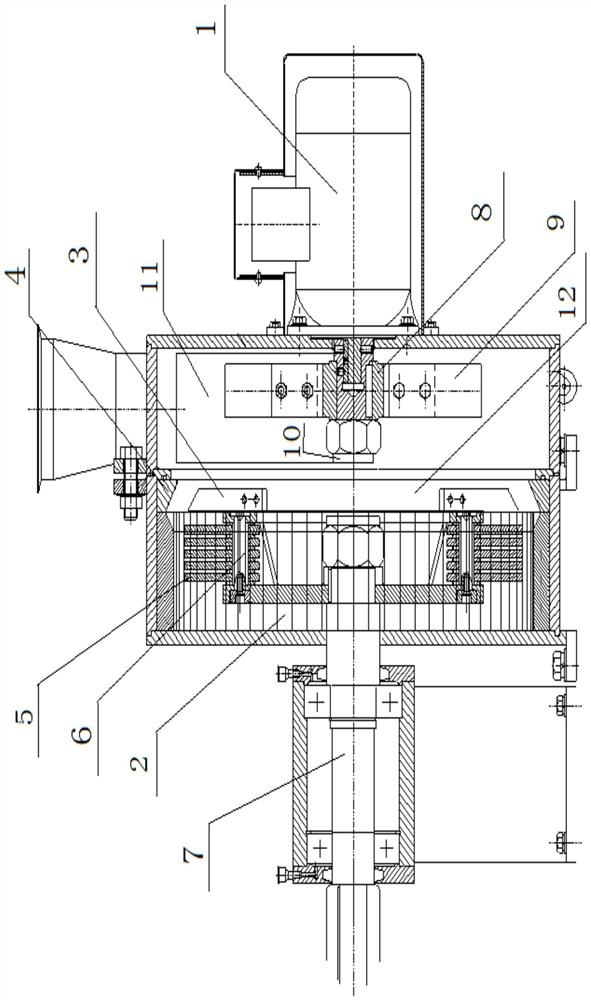

[0036] like Figure 1-7 , a crushing structure of an anti-sticking grinder, the structure includes a swinging knife rotating crushing device installed in a crushing chamber shell, a ring gear fixed crushing device, a conical knife rotating crushing device, a cone aperture fixed crushing device and another A powder discharge device on the housing;

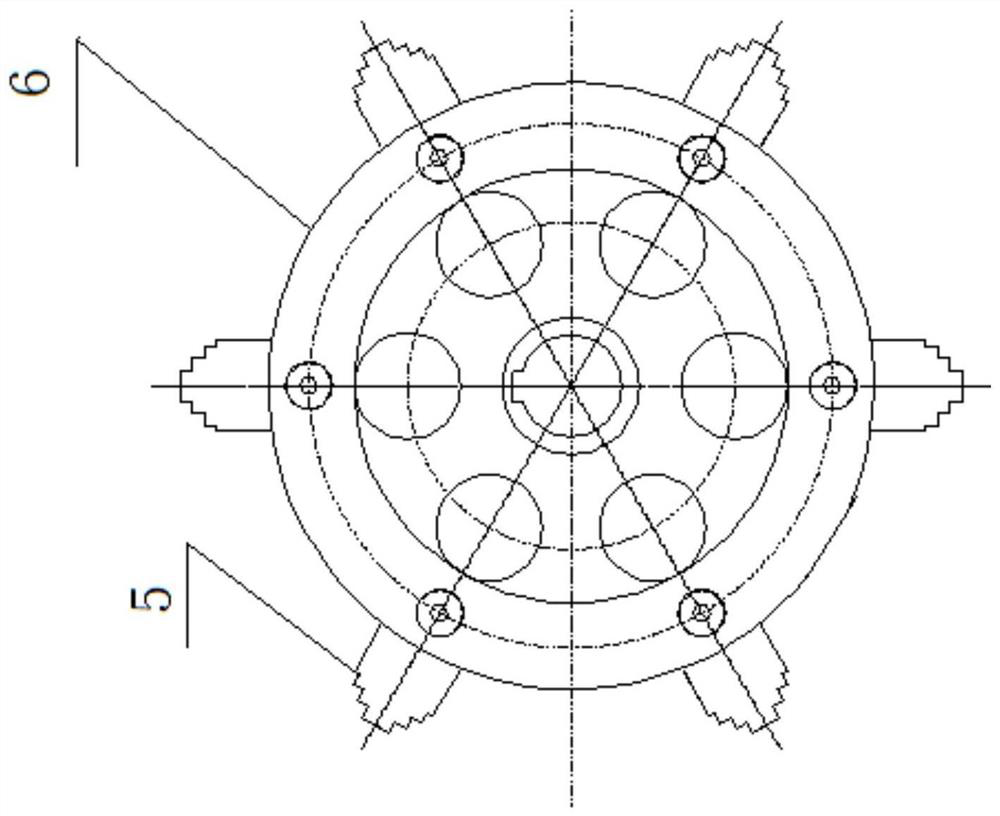

[0037] The pendulum knife rotary crushing device comprises a rotary pendulum knife support 6, and the pendulum knife 5 symmetrically arranged on the rotary pendulum knife support 6; Cone knife 3;

[0038] The rotary swing knife support 6 and the rotary cone knife support 12 are driven to rotate by the crushing shaft 7;

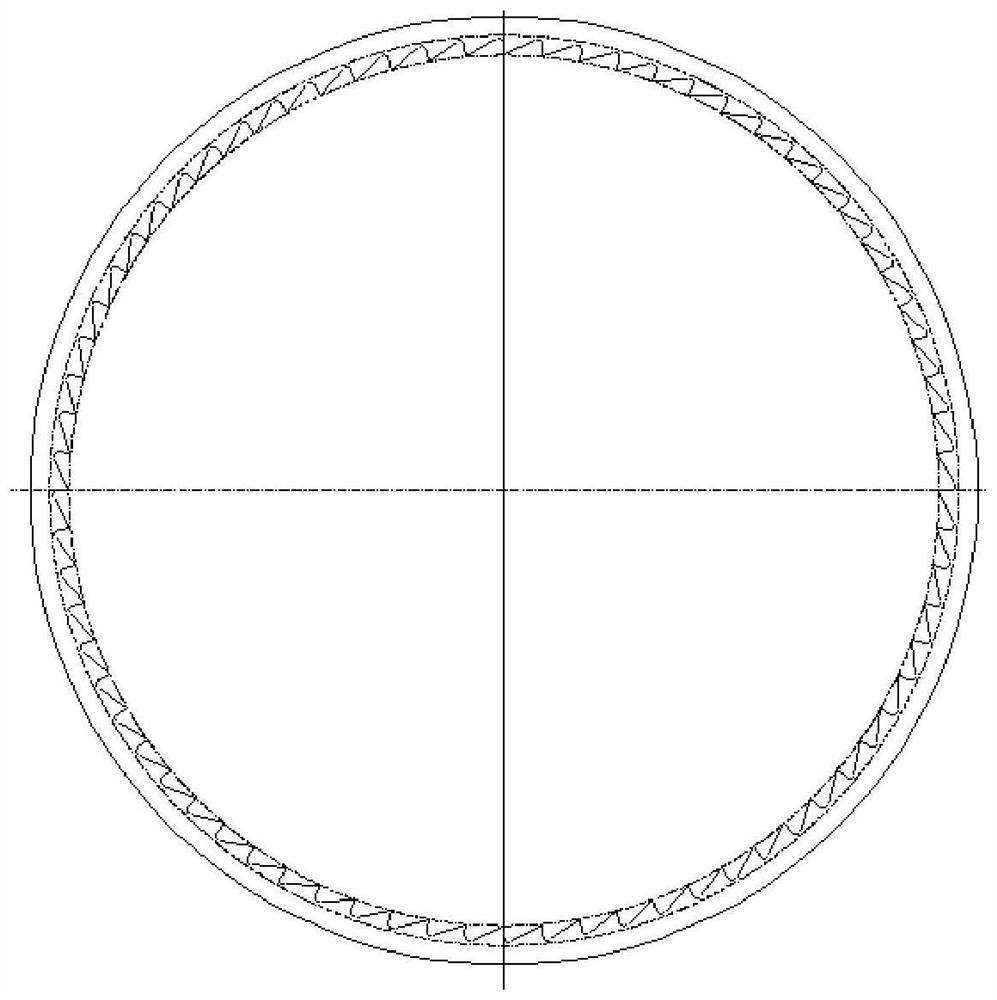

[0039] The straight ring gear 2 is fixed on the inner wall of the shell of the anti-stick crushing area at the corresponding position of the pendulum...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap