Electric tool part machining device capable of carrying outing grinding conveniently

A processing device and electric tool technology, applied in the direction of grinding drive device, grinding machine parts, manufacturing tools, etc., can solve the problem of reducing flexibility and stability, reducing balance and stability, reducing the grinding efficiency of parts, etc. problems, to achieve the effect of increasing flexibility and stability, improving balance and stability, and increasing stability and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

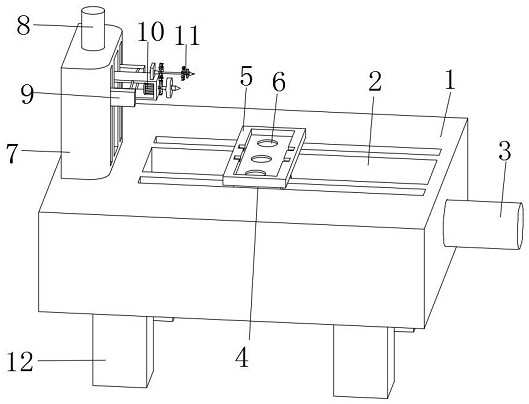

[0032] A processing device for electric tool parts that is convenient for grinding, such as Figure 1-2 As shown, including the processing main body 1, the upper right part of the processing main body 1 is provided with a sliding groove 2, and the middle part of the right end of the processing main body 1 is fixedly connected with a No. The sliding structure 4 is fixedly connected, the upper end of the sliding structure 4 is fixedly connected with the processing plate 5, the upper end of the processing plate 5 is provided with several different processing grooves 6, and the upper left part of the processing main body 1 is fixedly connected with the support frame 7, the support frame The upper end of 7 is fixedly connected with the No. 2 telescopic controller 8, the output end of the No. 2 telescopic controller 8 runs through the support frame 7 and is fixedly connected with the telescopic structure 9, the telescopic structure 9 is provided with a motor 10, and the output end of...

Embodiment 2

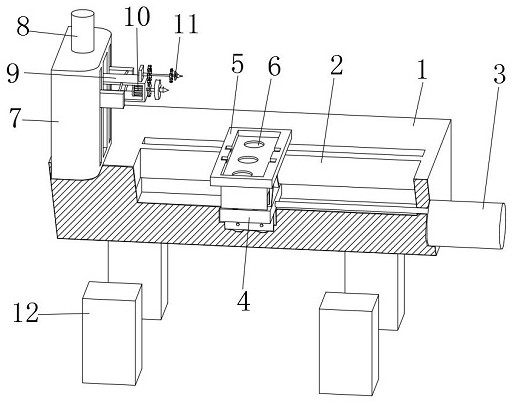

[0035] On the basis of Example 1, as Figure 3-4 As shown, a processing device for electric tool parts that is convenient for grinding includes a processing main body 1, a sliding groove 2 is opened on the upper right part of the processing main body 1, and a telescopic controller 3 is fixedly connected to the middle part of the right end of the processing main body 1. The output end of the telescopic controller 3 runs through the processing main body 1 and is fixedly connected with a sliding structure 4. The upper end of the sliding structure 4 is fixedly connected with a processing plate 5. The upper end of the processing plate 5 is provided with several different processing grooves 6. The processing main body 1 The left part of the upper end is fixedly connected with a support frame 7, and the upper end of the support frame 7 is fixedly connected with a No. A motor 10 is provided, the output end of the motor 10 runs through the telescopic structure 9 and is fixedly connecte...

Embodiment 3

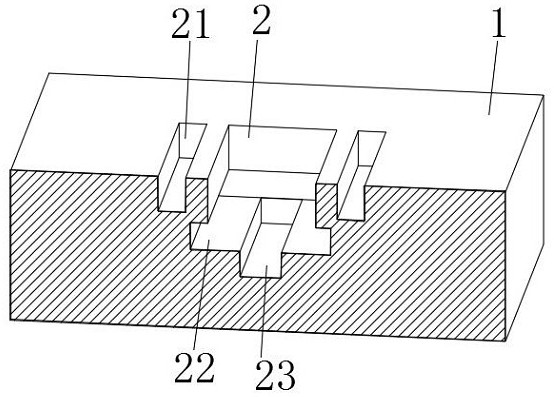

[0038] On the basis of Example 1, as Figure 5 and 6 As shown, a processing device for electric tool parts that is convenient for grinding includes a processing main body 1, a sliding groove 2 is opened on the upper right part of the processing main body 1, and a telescopic controller 3 is fixedly connected to the middle part of the right end of the processing main body 1. The output end of the telescopic controller 3 runs through the processing main body 1 and is fixedly connected with a sliding structure 4. The upper end of the sliding structure 4 is fixedly connected with a processing plate 5. The upper end of the processing plate 5 is provided with several different processing grooves 6. The processing main body 1 The left part of the upper end is fixedly connected with a support frame 7, and the upper end of the support frame 7 is fixedly connected with a No. A motor 10 is provided, the output end of the motor 10 runs through the telescopic structure 9 and is fixedly con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com