Grooving equipment for building water and electricity installation

A slotting equipment and installation technology, applied in stone processing equipment, work accessories, stone processing tools, etc., can solve the problems of inconvenient and stable connection, troublesome length adjustment, lack of hand protection, etc., to accelerate heat loss, increase Improved cutting range and height, safety concerns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

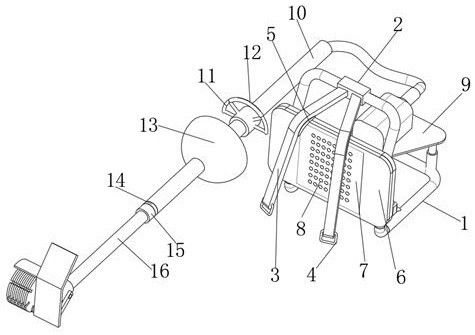

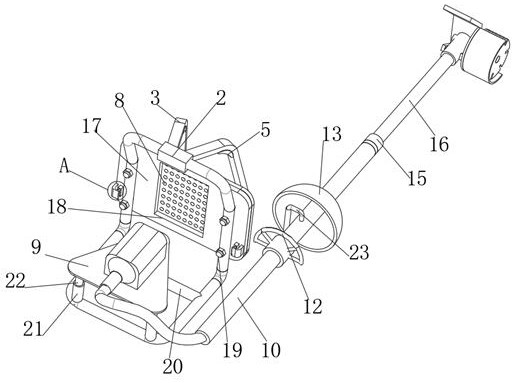

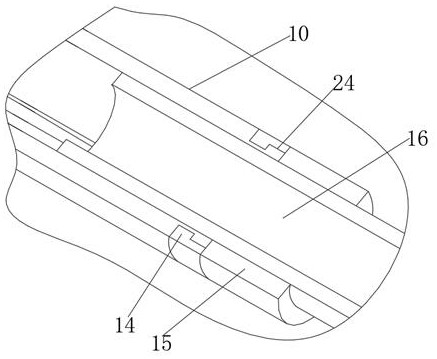

[0024] see Figure 1-7 , the present invention provides the following technical solutions: a slotting device for building water and electricity installation, including an installation frame 1, the upper end of the installation frame 1 is fixedly connected with a connection block 2, and the inside of the connection block 2 is provided with a stopper block 29 for snap-fit connection The back strap 3, the other end of the strap 3 is rotatably connected with a snap ring 4, the lower surface of the strap 3 is fixedly connected with a protective pad 5 for protection, the surface of the installation frame 1 is fixedly connected with a shock-absorbing pad 6, and the inside of the shock-absorbing pad 6 A heat-absorbing plate 7 is installed, and the surface of the heat-absorbing plate 7 is equidistantly arranged with several cooling holes 8, and the No. 1 fixed column 21 slidingly connected with the No. 2 fixed column 22 is installed on the top of the installation frame 1, and the No. ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap