Wafer film coating equipment

A film coating and equipment technology, applied in the field of wafer coating equipment, can solve the problems affecting the uniformity of the coating film on the wafer surface and the uneven placement of the wafer, and achieve the effect of avoiding the uneven placement of the wafer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

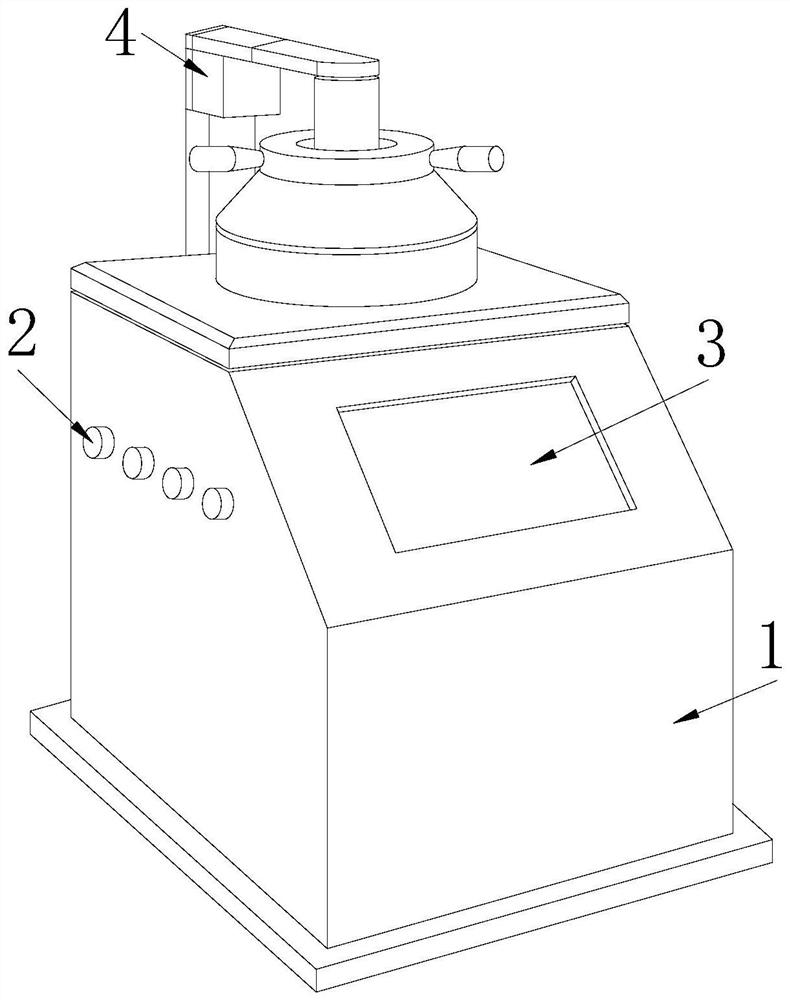

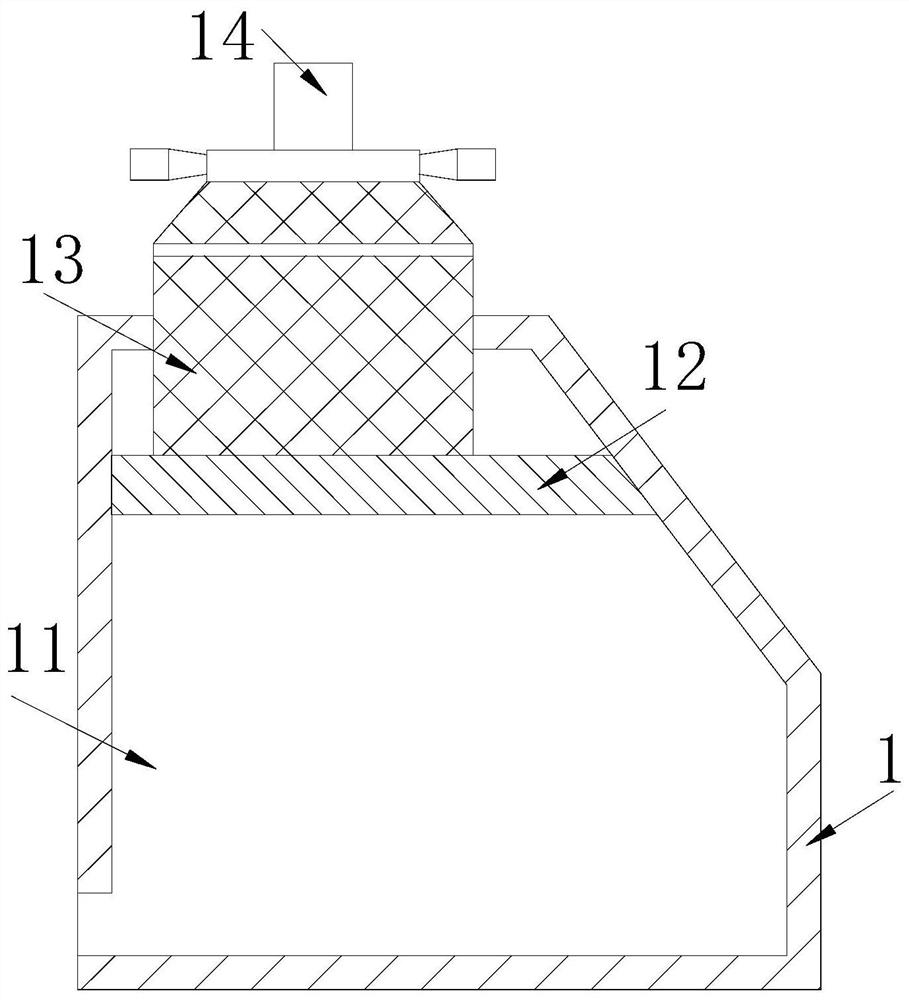

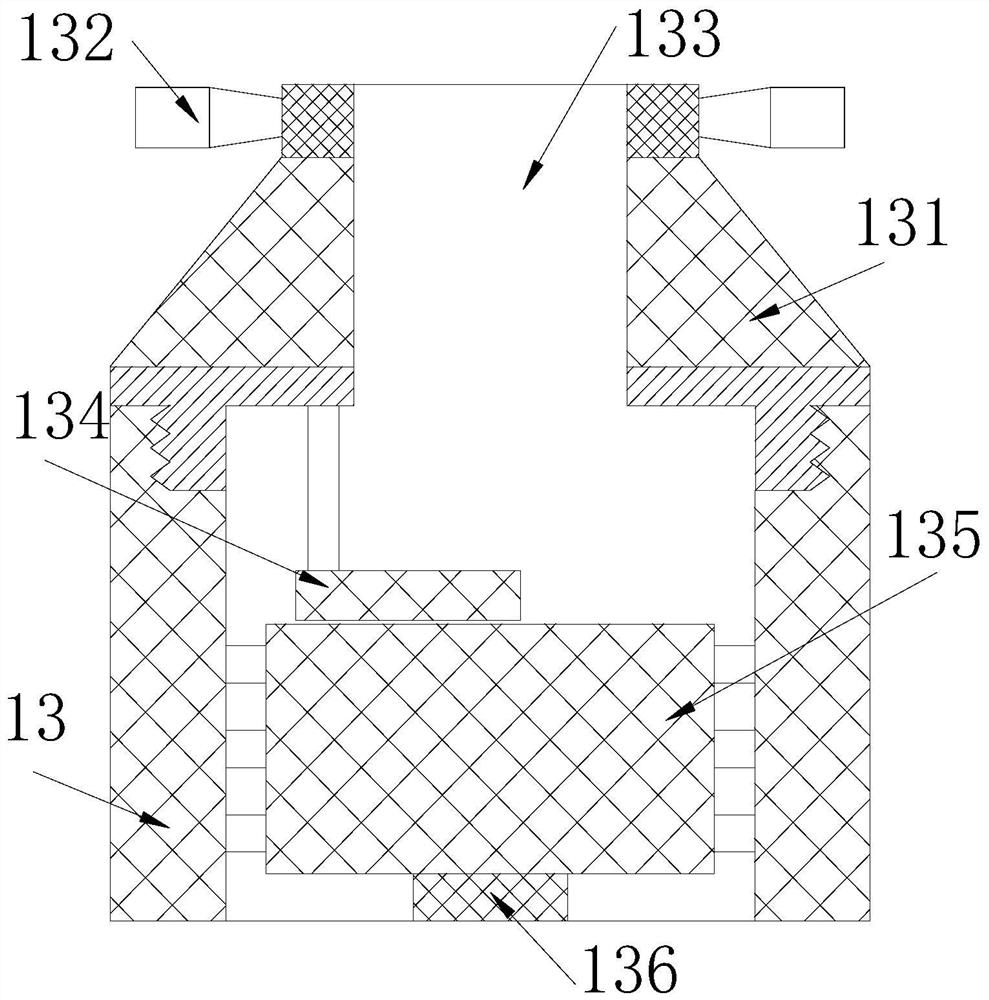

[0029] The present invention provides a wafer coating equipment, the structure of which includes a storage box 1, a button 2, a display 3, and a film feeder 4, the button 2 is installed on the left side of the storage box 1, and the display 3 is embedded in the storage box 1 front side, the two ends of the film feeder 4 are respectively connected to the back of the storage box 1 and the top of the storage box 1 by welding, the storage box 1 includes a storage cavity 11, a fixed plate 12, a film coating box 13, and a through pipe 14, The storage cavity 11 is embedded in the storage box 1, and the storage cavity 11 is connected to one end of the film delivery device 4, the fixed plate 12 is connected to the inner wall of the storage cavity 11 by horizontal welding, and the bottom of the coating box 13 is embedded Fixed on the upper surface of the fixed plate 12, the through pipe 14 is vertically arranged on the top of the film coating box 13, and the top of the through pipe 14 is...

Embodiment 2

[0036] The present invention provides a wafer coating equipment, the structure of which includes a storage box 1, a button 2, a display 3, and a film feeder 4, the button 2 is installed on the left side of the storage box 1, and the display 3 is embedded in the storage box 1 front side, the two ends of the film feeder 4 are respectively connected to the back of the storage box 1 and the top of the storage box 1 by welding, the storage box 1 includes a storage cavity 11, a fixed plate 12, a film coating box 13, and a through pipe 14, The storage cavity 11 is embedded in the storage box 1, and the storage cavity 11 is connected to one end of the film delivery device 4, the fixed plate 12 is connected to the inner wall of the storage cavity 11 by horizontal welding, and the bottom of the coating box 13 is embedded Fixed on the upper surface of the fixed plate 12, the through pipe 14 is vertically arranged on the top of the film coating box 13, and the top of the through pipe 14 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com